Graphene/oxide-based electrode material and lithium-sulfur battery comprising the electrode material

An electrode material, graphene technology, applied in lithium batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve the problems of high cost, difficult to control product structure, cumbersome preparation process, etc., to achieve low cost, avoid pollution, and abundant pores. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

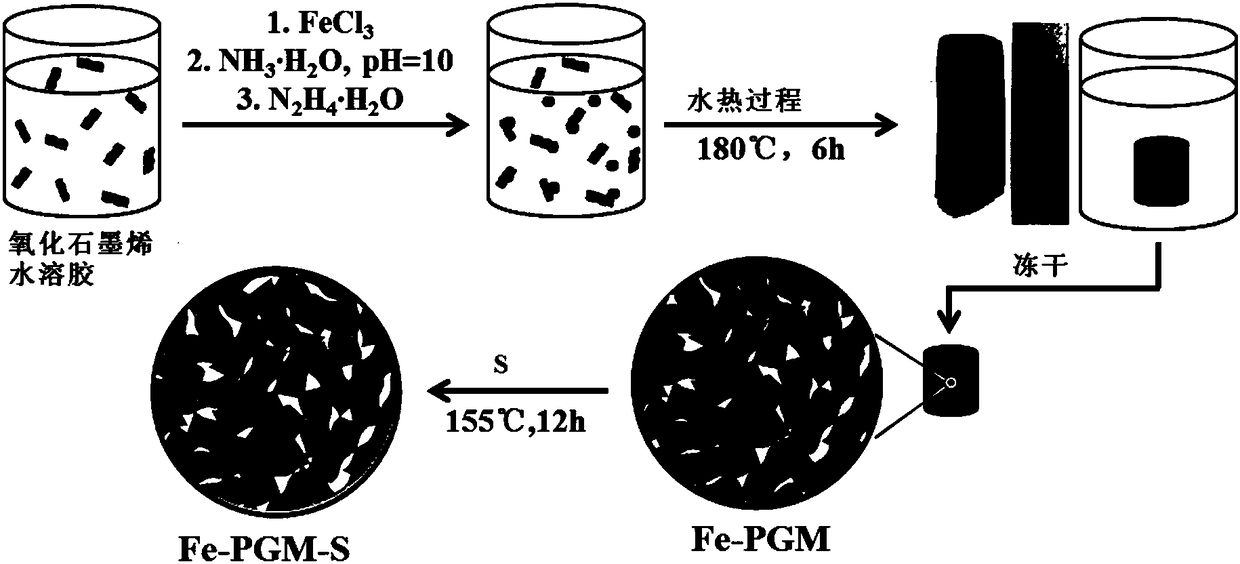

[0035] This embodiment provides a graphene / oxide-based electrode material. The electrode material includes nano-Fe 2 O 3 The composite formed by the porous macroscopic body of graphene and the nano-sulfur supported on the composite, wherein the nano-sulfur accounts for 60wt.% of the total mass of the electrode material, and the nano-Fe 2 O 3 It accounts for 15wt.% of the total mass of the electrode material, and the specific surface area of the composite is 800m 2 / g.

[0036] The preparation method includes the following steps:

[0037] S1: Add 10mg / mL FeCl to the graphene oxide hydrosol with a concentration of 2mg / mL under stirring conditions 3 The aqueous solution, continue to stir for 2h, and mix well to obtain a uniformly dispersed mixed solution, then add ammonia water (mass fraction of 28%) to the mixed solution, adjust the pH to 10, and obtain a mixed solution M1;

[0038] Wherein, the preparation method of the graphene oxide hydrosol is as follows: weigh the graphite oxide ...

Embodiment 2

[0044] This embodiment provides a graphene / oxide-based electrode material. The electrode material includes nano-Fe 2 O 3 The composite formed by the porous macroscopic body of graphene and the nano-sulfur supported on the composite, wherein the nano-sulfur accounts for 50wt.% of the total mass of the electrode material, and the nano-Fe 2 O 3 Accounting for 20wt.% of the total mass of the electrode material, the specific surface area of the composite is 500m 2 / g.

[0045] The preparation method includes the following steps:

[0046] S1: Add 8mg / mL FeCl to the graphene oxide hydrosol with a concentration of 3mg / mL under stirring conditions 3 The aqueous solution, continue to stir for 1 hour, and mix evenly to obtain a uniformly dispersed mixed solution, then add ammonia water (mass fraction of 28%) to the mixed solution, adjust the pH to 9.5, and obtain a mixed solution M1;

[0047] Wherein, the preparation method of graphene oxide hydrosol is as follows: weigh graphite oxide powder,...

Embodiment 3

[0052] This embodiment provides a graphene / oxide-based electrode material. The electrode material includes nano-Fe 2 O 3 The composite formed by the porous macroscopic body of graphene and the nano-sulfur loaded on the composite, wherein the nano-sulfur accounts for 40wt.% of the total mass of the electrode material, and the nano-Fe 2 O 3 Accounting for 12wt.% of the total mass of the electrode material, the specific surface area of the composite is 700m 2 / g.

[0053] The preparation method includes the following steps:

[0054] S1: Add 12mg / mL FeCl to the graphene oxide hydrosol with a concentration of 4mg / mL under stirring conditions 3 Aqueous solution, continue to stir for 3h, mix evenly to obtain a uniformly dispersed mixed solution, then add ammonia water (mass fraction of 28%) to the mixed solution, adjust the pH to 10.5, and obtain a mixed solution M1;

[0055] Wherein, the preparation method of graphene oxide hydrosol is as follows: Weigh graphite oxide powder, add deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com