Resin beads, method for manufacturing resin beads and product including resin beads

A technology of resin microbeads and monomers, applied in the direction of medical preparations containing active ingredients, dressing preparations, cosmetic preparations, etc., can solve the problems of compatibility and adhesion, loss of hydrophilicity, Loss of hydrophobicity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

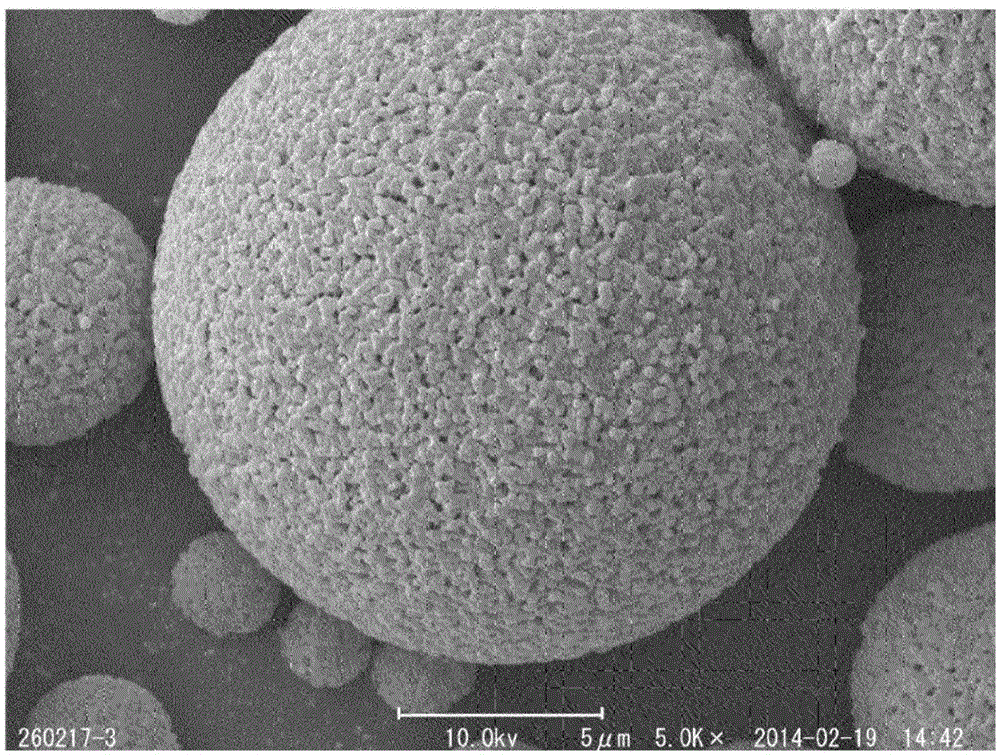

Image

Examples

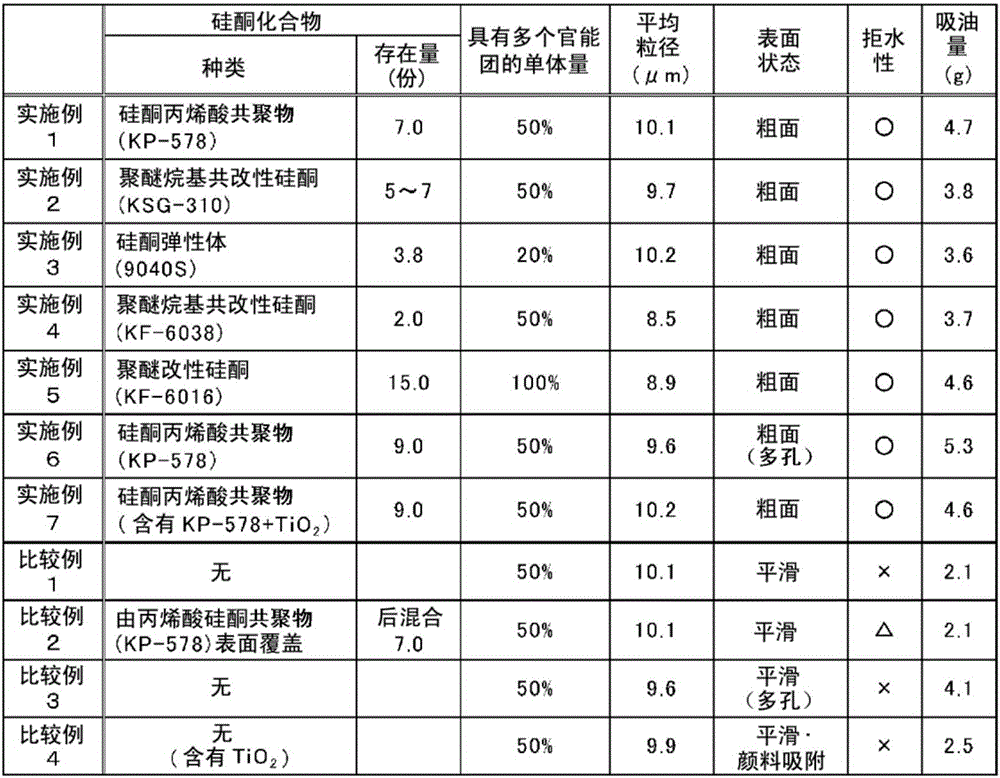

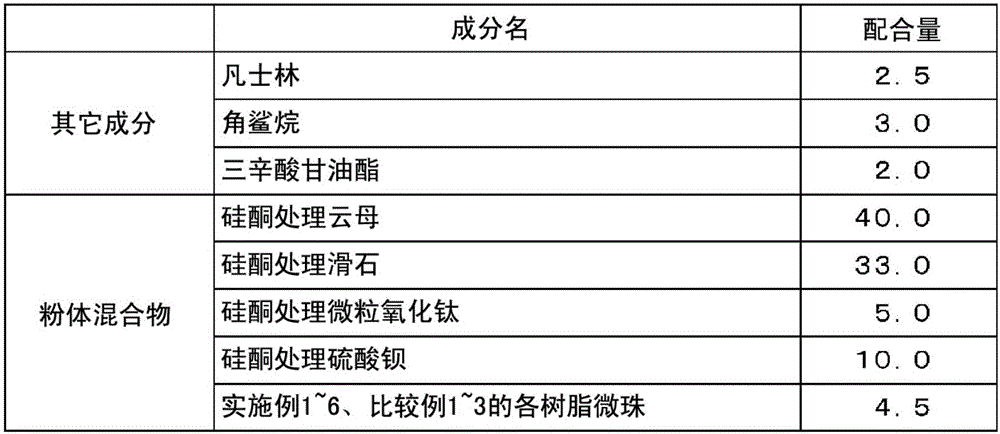

Embodiment 1

[0046] (Example of producing a non-polymerizable silicone acrylic copolymer in a polymerizable monomer liquid)

[0047] First, 200 parts of lauryl methacrylate was added to a solution in which 4 parts of V-65 was dissolved in 200 parts of polyethylene glycol dimethacrylate (manufactured by Shin-Nakamura Chemical Industry Co., Ltd., trade name: NK1G) prepared in advance. (manufactured by Kao Corporation, trade name: LMA) and 28 parts of non-polymerizable silicone acrylic copolymers (manufactured by Shin-Etsu Chemical Industry Co., Ltd., trade name: KP-578, active ingredient 100%), and they are uniformly stirred and mixed , to prepare a polymerizable monomer liquid. KP-578 used above is a graft copolymer formed of acrylic polymer and dimethyl polysiloxane. The viscosity at 25°C is 150 to 200 mPa·s.

[0048] Next, in another container, 80 parts of PVA as a dispersion stabilizer was dissolved in 1600 parts of ion-exchanged water, and the polymerizable monomer liquid prepared ab...

Embodiment 2

[0050] (Example of producing a non-polymerizable polyether alkyl co-modified silicone in a polymerizable monomer liquid)

[0051] First, 200 parts of butyl methacrylate (manufactured by Mitsubishi Rayon Co., Ltd.), 80 parts 20 parts of non-polymerizable polyether alkyl co-modified silicone (manufactured by Shin-Etsu Chemical Co., Ltd., trade name: KSG-310, active ingredient 25-35%) and 20 parts of propylene glycol monomethyl ether acetate Solution with 4 parts of V-65 dissolved. Then, these are uniformly stirred and mixed to prepare a polymerizable monomer liquid. Next, in another container, the aqueous phase in which 88 parts of PVA as a dispersion stabilizer was dissolved in 1600 parts of ion-exchanged water was used, except that the subsequent cleaning and other operations were carried out in the same manner as in Example 1 to obtain Resin beads made of a non-polymerizable silicone compound were used as the resin beads of this example. KSG-310 used above is a mixture of...

Embodiment 3

[0052] (Example of producing a polymerizable monomer liquid containing a non-polymerizable silicone elastomer)

[0053] Add 320 parts of methacrylic acid to a solution in which 4 parts of V-65 were dissolved in 80 parts of hexanediol dimethacrylate (manufactured by Shin-Nakamura Chemical Industry Co., Ltd., trade name: NK ester HD-N) prepared in advance. Lauryl ester (manufactured by Kao Corporation, trade name: LMA) and 100 parts of non-polymerizable silicone elastomers (manufactured by Dow Corning Toray Co., Ltd., trade name: 9040S.E.B, active ingredient 15%) were subjected to Stir and mix uniformly to prepare a polymerizable monomer liquid, except that, in the same manner as in Example 1, resin beads containing a non-polymerizable silicone compound immobilized inside were obtained, which were used as this example. resin beads. The silicone elastomer (trade name: 9040S.E.B) used above was a mixture of 12% of dimethicone crosspolymer and 88% of cyclopentasiloxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com