Vehicle-mounted electrical wire and cable

A technology of cables and wires, which is applied in the field of automotive wires and cables, can solve the problems of low strength, hard fluororesin, and problems with wiring layout, and achieve the effect of high flexibility and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

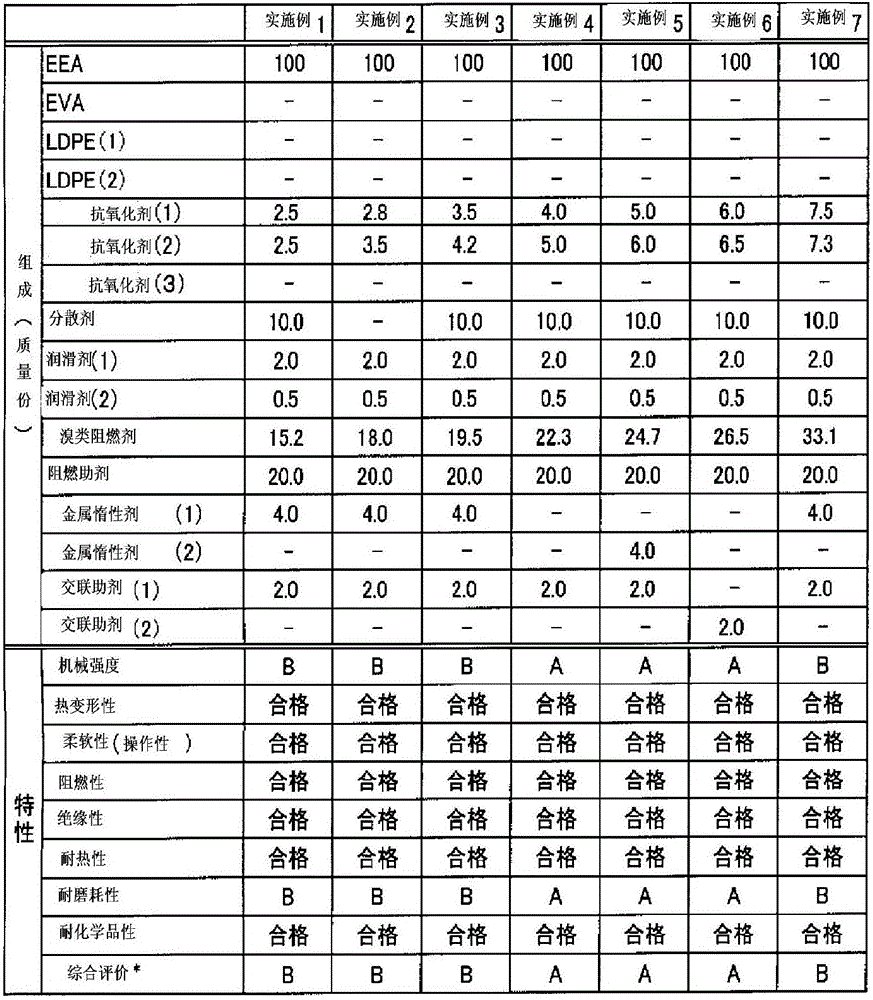

[0096] 100.0 parts by mass of EEA, 2.5 parts by mass of antioxidant (1), 2.5 parts by mass of antioxidant (2), 10.0 parts by mass of dispersant, 2.0 parts by mass of lubricant (1), 0.5 parts by mass of lubricant (2) Parts by mass, 15.2 parts by mass of a flame retardant, 20.0 parts by mass of a flame retardant aid, 4.0 parts by mass of a metal inert agent (1), and 2.0 parts by mass of a crosslinking aid (1) were uniformly kneaded to obtain a resin composition.

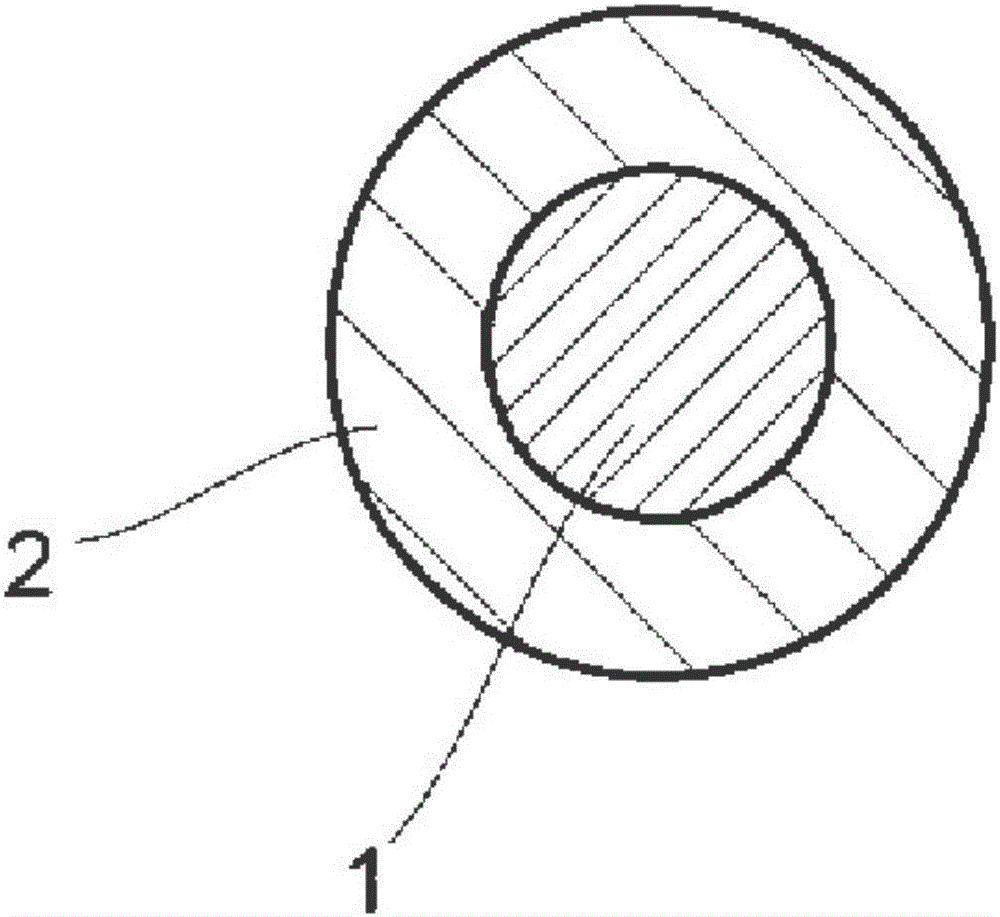

[0097] Then, the resin composition was extruded and coated on a copper twisted wire conductor with an outer diameter of about 3 mm, and cross-linked by electron beam irradiation (30 Mrad radiation dose) to obtain an insulated wire with an outer diameter of about 4.4 mm.

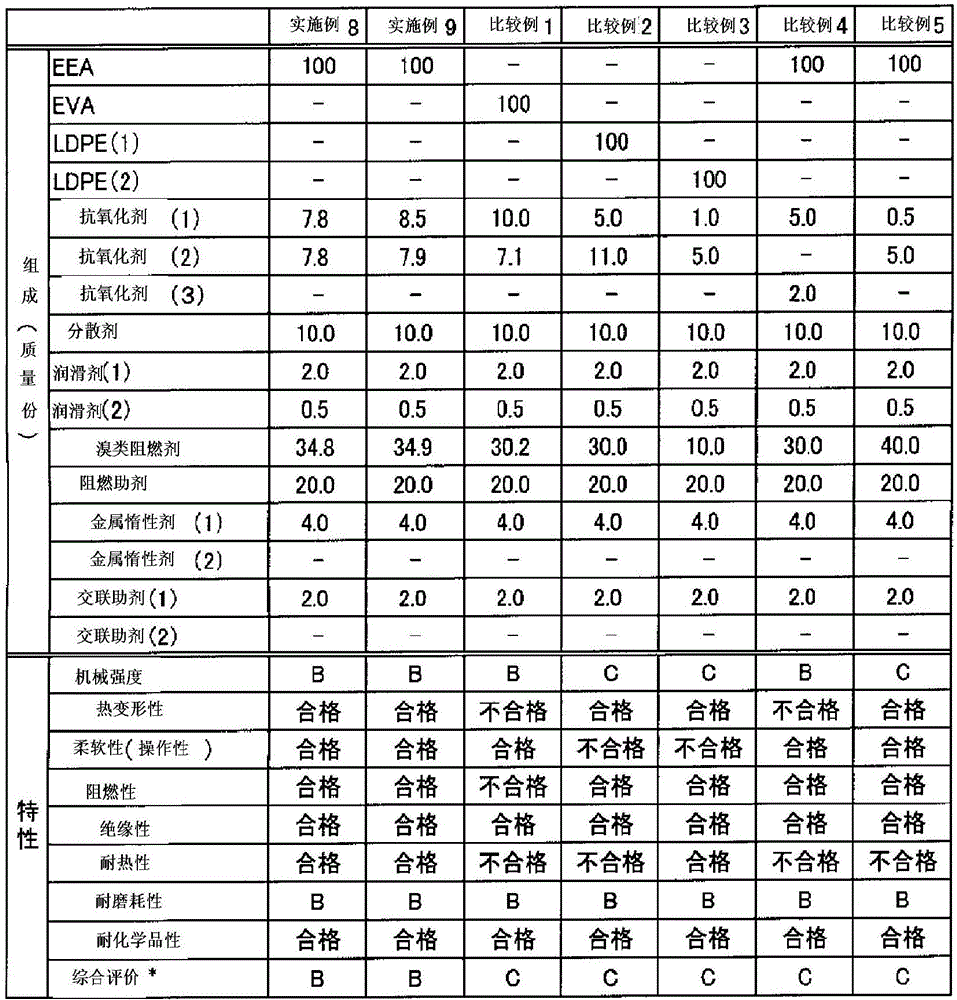

Embodiment 2~9、 comparative example 1~5

[0099] Except that the composition of the resin composition was changed as shown in Table 1, flame-retardant resin compositions were prepared in the same manner as in Example 1, and insulated wires were produced using these compositions.

[0100] Various characteristics of the insulated wires obtained in the aforementioned Examples and Comparative Examples were measured and evaluated by the methods shown below.

[0101] [Mechanical strength (tensile strength)]

[0102]According to JASO (Japan Automobile Technical Association Standard) D 618, for a ring-shaped test piece made by pulling out the inner conductor from an insulated wire with a length of 150mm, under the conditions of a tensile speed of 500mm / min and a punctuation distance of 50mm, measure Tensile strength (MPa) was evaluated based on the following criteria.

[0103] A: Above 20MPa;

[0104] B: More than 10MPa and less than 20MPa;

[0105] C: Less than 10 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com