Method for preparing plate-type straw biological seedling culture medium with dry process

A technology of straw biology and seedling-raising substrate, which is applied in application, cultivation, agriculture, etc., can solve the problems of low added value of straw, waste of resources, and low consumption, and achieve high added value, reduced production and use costs, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

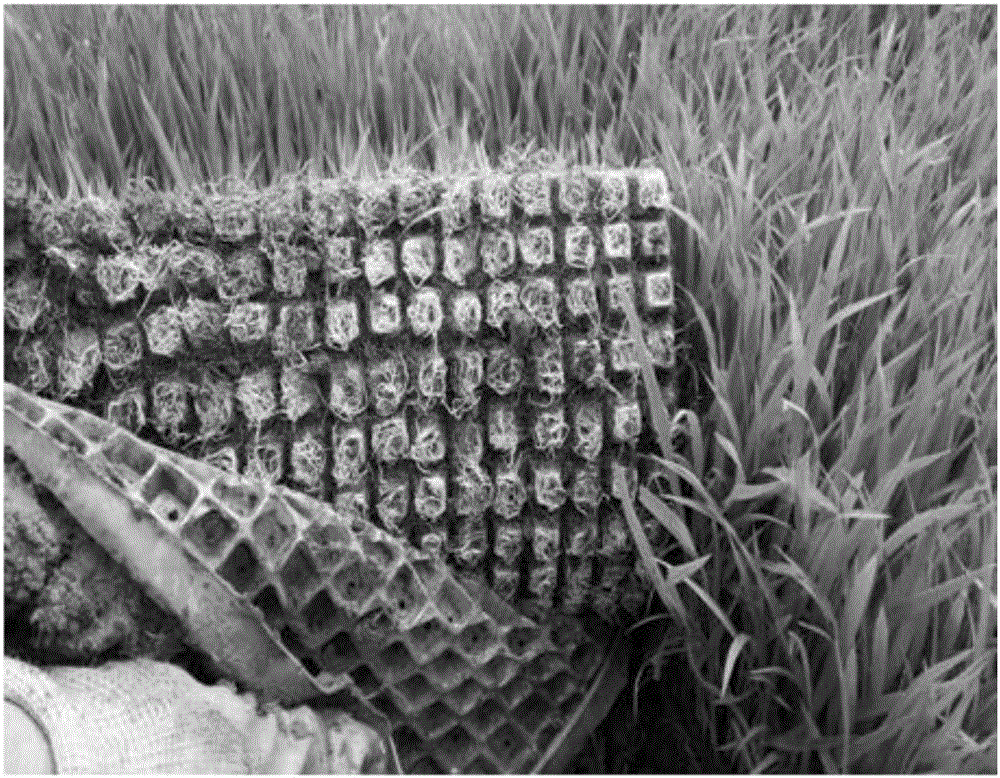

Image

Examples

specific Embodiment approach 1

[0023] Specific implementation mode 1: In this implementation mode, the plate-type straw biological seedling raising substrate is prepared according to the following steps:

[0024] 1. Cut off the straw, and then use the plunger screw method to send it into the cooking tank for cooking and softening;

[0025] 2. Grinding and kneading the softened stalks in step 1 to form stalk fibers, and then drying;

[0026] 3. Mix a part of dried straw fiber with solid adhesive and solid water-retaining agent in proportion and send it to the surface silo; mix another part of dried straw fiber with solid nutrient, trace elements, solid adhesive, The solid water retaining agent and solid additives are mixed in proportion and sent to the core silo;

[0027] Four, use the mixture in the silo to pave the plate-type straw biological seedling raising matrix slab;

[0028] 5. After the slab is pre-pressed, it is hot-pressed to obtain a plate-type straw biological seedling-raising substrate;

[0...

specific Embodiment approach 2

[0043] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solid nutrient is a compound fertilizer, and the mass ratio of the solid nutrient to trace elements is 1:1.5-4. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0044]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the cut stalks in step 1 are cooked and softened for 2-6 hours at a pressure of 0.3-1.5 MPa and a temperature of 110°C-180°C. minute. Other steps and parameters are the same as those in Embodiment 1 or 2.

[0045] While steaming and softening, high-temperature sterilization is carried out to Pythium straw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com