Method of preparing Al/Bi2O3 nano energetic material composite thin film

A composite thin film and nanotechnology, applied in the direction of electrolytic coatings, coatings, etc., can solve the problems of affecting the stability of energetic materials, unfavorable adhesion of energetic materials, poor uniformity of deposited films, etc., to achieve good market application prospects, film The effect of controllable thickness and uniform distribution of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

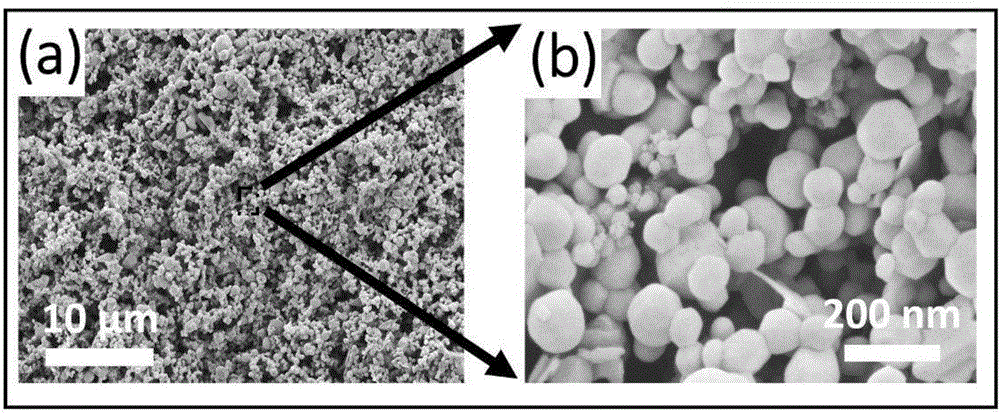

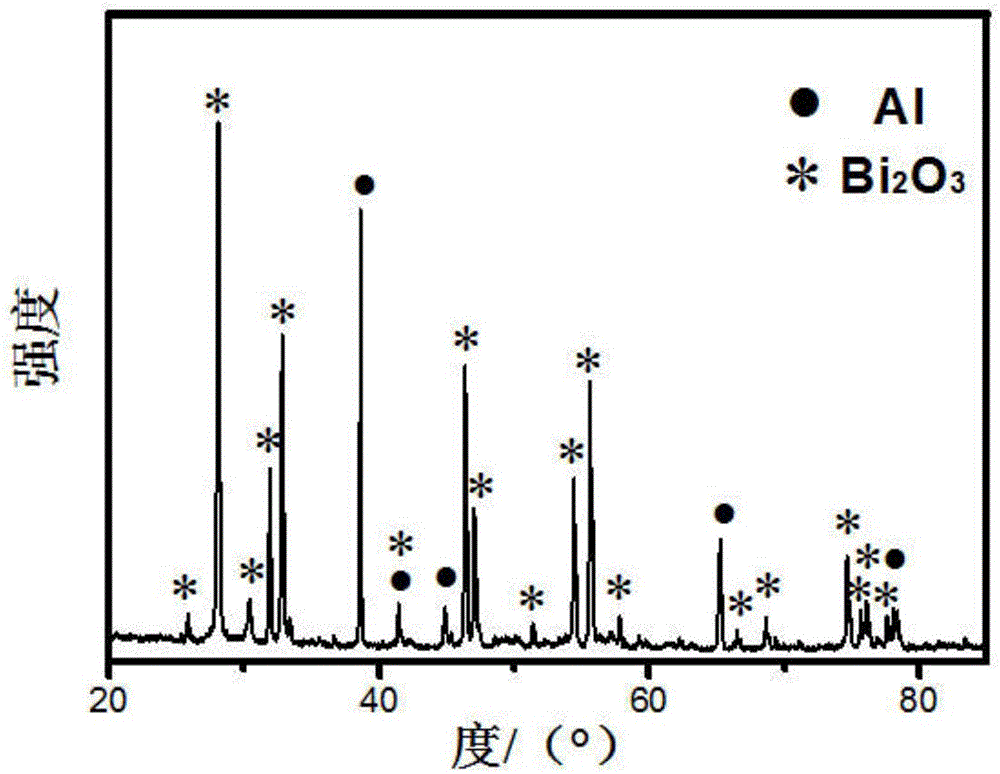

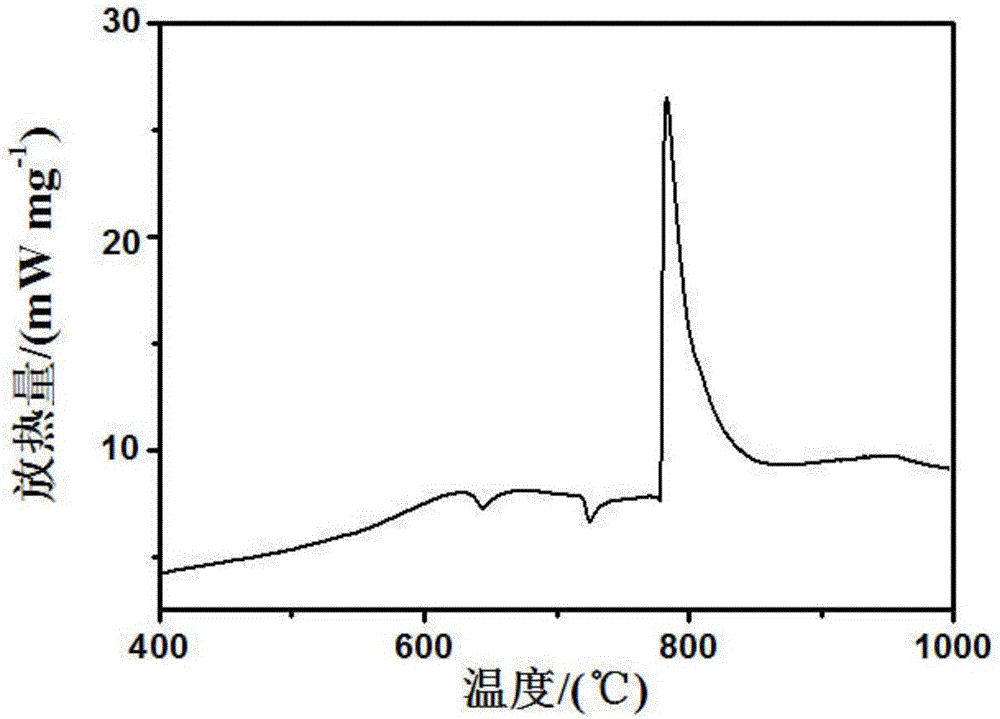

[0026] Accurately weigh 0.1 mL of polyethyleneimine, dissolve it in 100 mL of ethanol solution, and sonicate for 1 hour at 298±1K. Weigh 0.1 g of nano aluminum particles and 0.9 g of bismuth trioxide nanoparticles into the above-mentioned mixed suspension, and after sealing with a plastic film, perform ultrasound at 298±1K for 20 minutes. Then, 3 mL of methacryloxysilane was weighed and added to the upper suspension and then sonicated at the same temperature for 20 minutes. Immediately insert the pre-treated titanium cathode and anode materials vertically into the stable suspension, and the applied electric field is 25Vmm -1 , Electrophoresis deposition is 20 minutes, and the deposition temperature is controlled at 298±1K. Then the Al / Bi obtained from the deposit 2 O 3 The nano-energetic material composite film is transferred to a vacuum drying oven and dried for 2 hours at 353~423±1K, and then cooled to room temperature. Al / Bi 2 O 3 Nano energetic material composite film.

[0...

Embodiment 2

[0034] Similar to Example 1, the difference is that the nanoparticle binder-methacryloxysilane is not added to the dispersion medium, and only polyethyleneimine is added as a surfactant to improve the surface charge of the nanoparticles. Adhesion level measured by the tape method is 2B.

Embodiment 3

[0036] Accurately weigh 0.1 mL of polyethyleneimine, dissolve it in 100 mL of ethanol solution, and sonicate for 1 hour at 298±1K. Weigh 0.1 g of nano aluminum particles and 0.9 g of bismuth trioxide nanoparticles into the above-mentioned mixed suspension, and after sealing with a plastic film, perform ultrasound at 298±1K for 20 minutes. Then, 3 mL of aminosilane was weighed and added to the upper suspension, followed by ultrasound at the same temperature for 20 minutes. Immediately insert the pre-treated titanium cathode and anode materials vertically into the stable suspension, and the applied electric field is 5-25Vmm -1 , Electrophoresis deposition is 20 minutes, and the deposition temperature is controlled at 298±1K. Then the Al / Bi obtained from the deposit 2 O 3 The nano-energetic material composite film is transferred to a vacuum drying oven and dried for 2 hours at 353~423±1K, and then cooled to room temperature. Al / Bi 2 O 3 Nano energetic material composite film. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com