Tableted sugar capable of reducing blood fat

A technology for tableting candies and reducing blood lipids, which is applied in confectionery, confectionary industry, plant raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

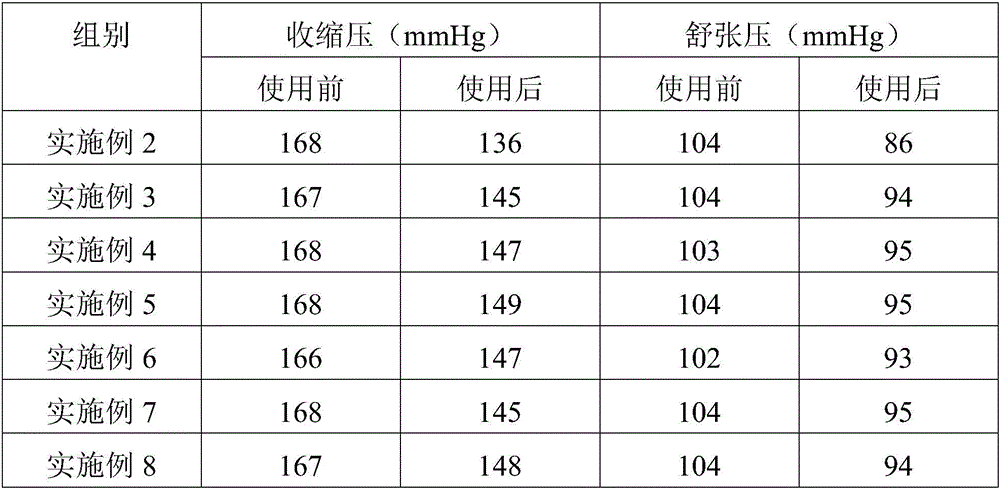

Examples

preparation example Construction

[0038] The preparation method of the hawthorn extract is as follows: add 30kg of water to 2kg of hawthorn and heat it to 95°C for 3 hours, then filter it with a 300-mesh filter cloth to obtain a primary filtrate and a primary filter residue, add 30kg of water to the primary filter residue and heat it to 95°C to keep it warm After 1.5 hours, filter with a 300-mesh filter cloth to obtain the secondary filtrate and secondary filter residue, combine the primary filtrate and the secondary filtrate, and concentrate the filtrate into a thick paste with a density of 1.30g / mL (20°C).

[0039] The preparation method of the lotus leaf extract is as follows: add 30kg of water to 2kg of lotus leaves and heat it to 95°C for 3 hours, then use a 300-mesh filter cloth to filter to obtain a primary filtrate and a primary filter residue, and add 30kg of water to the primary filter residue and heat to 95°C. Incubate at ℃ for 1.5 hours, then filter with a 300-mesh filter cloth to obtain the seconda...

Embodiment 1

[0049] Blood lipid-lowering compressed tablet candy raw materials (parts by weight): 200 parts of earthworm protein powder, 300 parts of hawthorn extract, 200 parts of lotus leaf extract, 558 parts of peach fruit powder, 11.5 parts of peach flavor, 118 parts of isomalt , 75 parts of microcrystalline cellulose, 22.5 parts of hydroxypropyl methylcellulose, and 15 parts of magnesium stearate.

[0050] The preparation method of pressed tablet candy for reducing blood fat comprises the following steps:

[0051] (1) Mix earthworm protein powder, hawthorn extract, lotus leaf extract, peach fruit powder, peach flavor, isomalt, and microcrystalline cellulose at a speed of 300 rpm for 10 minutes; then Add hydroxypropyl methylcellulose and stir at a speed of 300 rpm for 10 minutes to mix evenly, and granulate with a 16-mesh sieve to obtain wet granules;

[0052] (5) Dry the wet granules in a drying oven at 50°C for 12 hours, and sieve with a 20-mesh sieve to obtain dry granules;

[005...

Embodiment 2

[0055] Blood lipid-lowering compressed tablet candy raw materials (parts by weight): 200 parts of earthworm protein powder, 300 parts of hawthorn extract, 200 parts of lotus leaf extract, 558 parts of peach fruit powder, 11.5 parts of peach flavor, 117 parts of sugar alcohol, microcrystalline Cellulose 75 parts, hydroxypropyl methylcellulose 22.5 parts, magnesium stearate 15 parts.

[0056] The sugar alcohol is obtained by uniformly mixing isomalt, maltotetralitol and L-sorbitol in a mass ratio of 1:1:1.

[0057] The preparation method of pressed tablet candy for reducing blood fat comprises the following steps:

[0058] (1) Mix earthworm protein powder, hawthorn extract, lotus leaf extract, peach fruit powder, peach essence, sugar alcohol, and microcrystalline cellulose at a speed of 300 rpm for 10 minutes; then add hydroxypropyl The methylcellulose was stirred at 300 rpm for 10 minutes to mix evenly with a rotating speed of 300 rpm, and was granulated with a 16-mesh sieve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com