Sodium formate synthesis device and method

A technology of sodium formate and autoclave, which is applied in feeding devices, chemical instruments and methods, carboxylate preparation and other directions, can solve the problems of slow reaction speed, inability to apply industrial production, and no production equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained in conjunction with specific embodiments below.

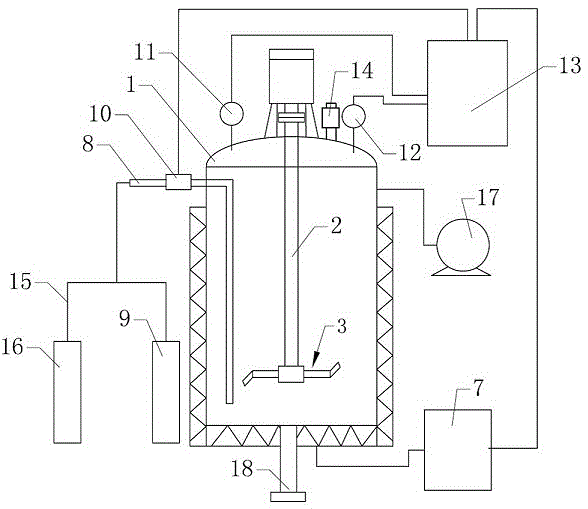

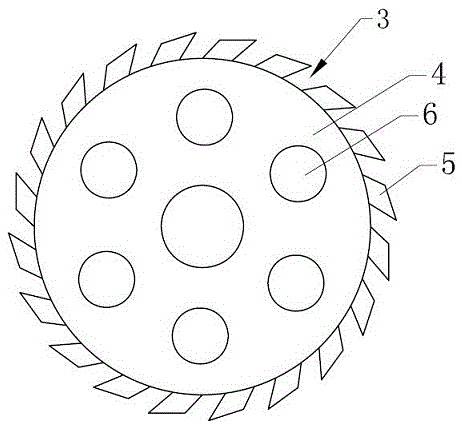

[0028] Such as figure 1 with figure 2 As shown, a device for synthesizing sodium formate includes an autoclave 1. A stirring shaft 2 driven by a driving device is installed on the axis of the autoclave 1, and a stirring blade 3 is installed at the lower end of the stirring shaft 2. The blade 3 includes a disc body 4 arranged coaxially with the stirring shaft 2, a stirring wing 5 with an inclined angle is arranged on the edge of the disc body 4, and the disc body 4 is uniformly provided with interference flow holes 6; An electric heater 7 is installed on the outer wall of the autoclave 1, and the upper cover of the autoclave 1 is provided with an air inlet pipe 8 extending into the lower part of the autoclave. The air inlet pipe 8 is connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com