Coaxial impinging-stream reactor and method for continuously preparing nanometer material

A technology of impinging flow reactors and nanomaterials, applied in chemical methods for liquid-liquid reactions, chemical instruments and methods, chemical/physical/physicochemical fixed reactors, etc., can solve the problem of single channel and achieve equipment Small size, promote full mixing and chemical reaction, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

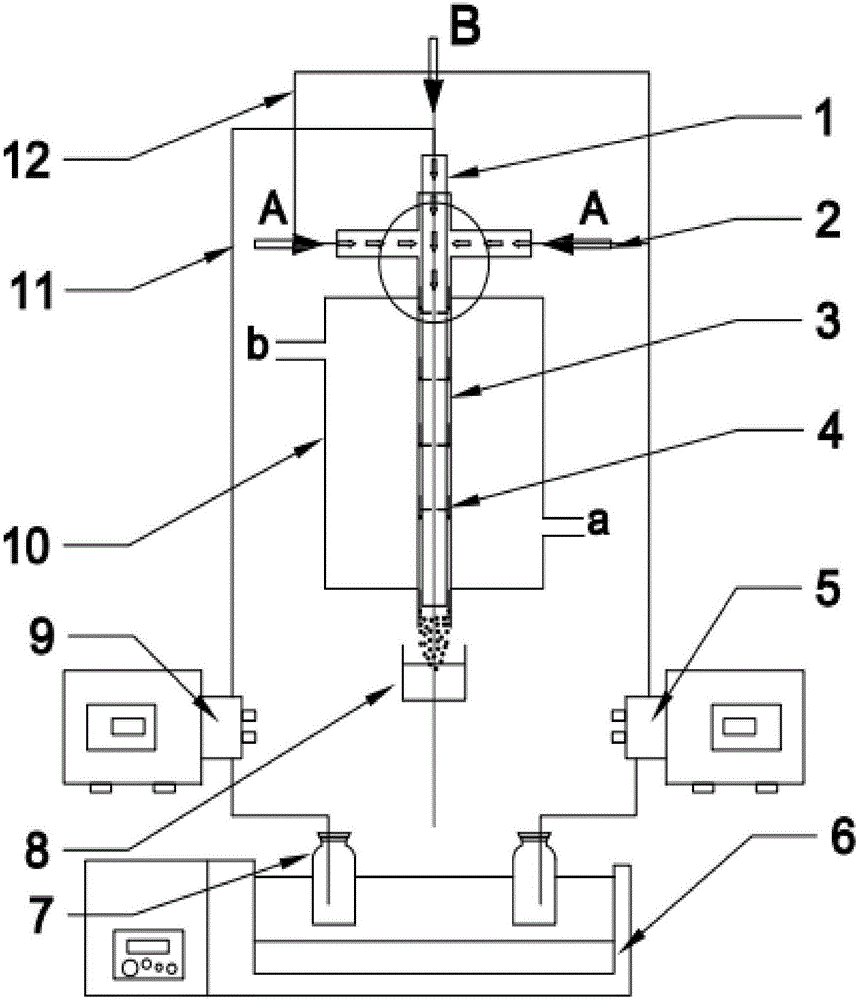

[0021] The specific embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing: the coaxial impinging flow reactor that can be used for the continuous production of nanometer material designed in this implementation example, its structure schematic diagram sees specification attached figure 1 , mainly including reactor inner pipe (1), feed pipe 2 (2), reactor outer pipe (3), micropore (4), electronic peristaltic pump 1 (5), constant temperature water bath (6), storage material device (7), collector (8), electronic peristaltic pump 2 (9), hot water circulation type incubator (10), feed pipe 1 (11), feed pipe 3 (12).

[0022] In this implementation example, both the inner tube of the reactor and the outer tube of the reaction zone are made of 316L stainless steel. The inner tube of the reactor is 200mm long, the inner diameter is 2mm, and the outer diameter is 3mm. 12mm, 5 micro-holes are uniformly opened in the radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com