Ultrasound-electromagnetic continuous casting method for alloy steel

An alloy steel and ultrasonic technology is applied in the application field of ultrasonic-electromagnetic composite energy field in the solidification and forming process of high-temperature melts to achieve the effects of reducing attenuation, preventing corrosion and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Put 30 tons of smelted 35CrMo molten steel into the tundish after vacuum degassing treatment, add a certain amount of covering agent on the surface of the molten steel in the molten pool to keep the temperature of the molten steel at 1550°C to 1560°C.

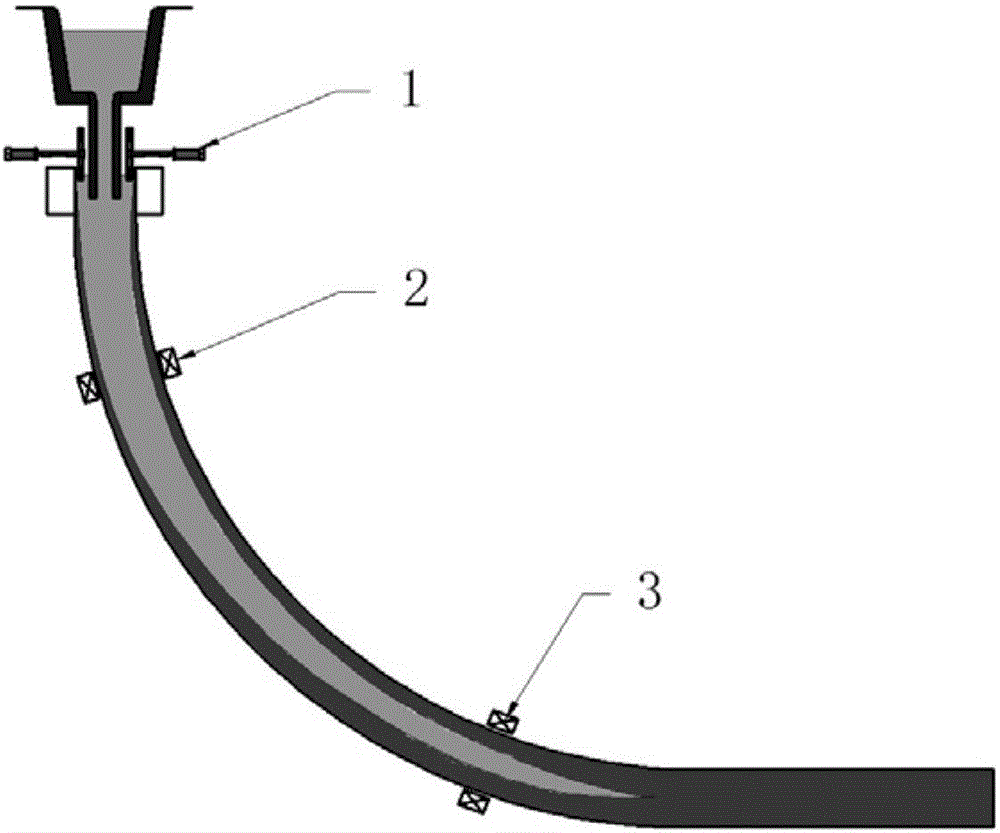

[0027] After the molten steel is pulled out of the crystallizer with a dummy rod, the red billet passes through the electromagnetic stirrer body 2 in the secondary cooling section. When the billet drawing speed reaches 1.50m / min, the industrial computer gives a signal to control the one-way rotation stirring current as 100A, stirring frequency 14Hz, generating an alternating magnetic field to stir the molten steel in the secondary cooling section. At the same time, according to the quality of the slab, adjust the casting speed to 2.00-2.50m / min and the mold cooling water to 20-30m 3 / h; control the cooling water volume of the agitator body ≥ 10m 3 / h, take away the radiant heat of the red billet to the agitator body and...

Embodiment 2

[0032] Put 30 tons of smelted 35CrMo molten steel into the tundish after vacuum degassing treatment, add a certain amount of covering agent on the surface of the molten steel in the molten pool to keep the temperature of the molten steel at 1550°C to 1560°C.

[0033] After the molten steel is pulled out of the crystallizer with a dummy rod, the red billet passes through the electromagnetic stirrer body 2 in the secondary cooling section. When the billet drawing speed reaches 1.50m / min, the industrial computer gives a signal to control the one-way rotation stirring current as 150A, stirring frequency 18Hz, generating an alternating magnetic field to stir the molten steel in the secondary cooling section. At the same time, according to the quality of the slab, adjust the casting speed to 2.00-2.50m / min and the mold cooling water to 20-30m 3 / h; control the cooling water volume of the agitator body ≥ 10m 3 / h, take away the radiant heat of the red billet to the agitator body and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Top diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com