Antibacterial plastic for toys and preparation method of antibacterial plastic

A technology for antibacterial plastics and toys, applied in the field of plastics, can solve the problems of high use cost, complicated preparation method, insufficient antibacterial effect, etc., and achieve the effects of good impact resistance, simple preparation process, and health protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

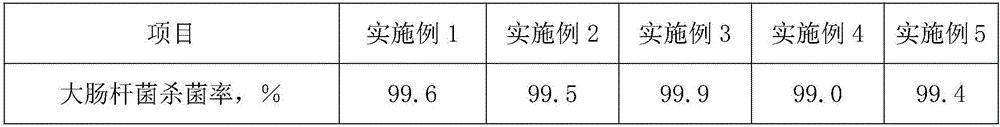

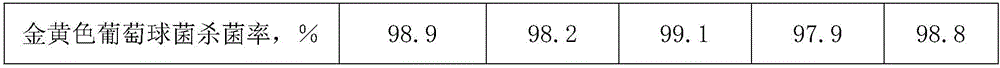

Examples

Embodiment 1

[0018] A preparation method of antibacterial plastics for toys, the specific steps are: (1) weighing 30 parts of polyvinyl chloride, 10 parts of ABS engineering plastics, 1 part of di-n-octyltin dilaurate, 0.5 parts of calcium phosphate, 0.5 part of methyl hydrojasmonate, 1 part of polysaccharide, 1 part of lauryltrimethylammonium chloride, 3 parts of ketone, 1 part of betaine; (2) lauryltrimethylammonium chloride and betaine after cleaning, crushing, grinding, drying, and sieving to obtain powder; (3) mix the powder with bamboo leaf ketone evenly, add polysaccharide, and stir while adding; (4) mix calcium phosphate and Methyl dihydrojasmonate was mixed at 35°C and stirred for 10 minutes to obtain a mixed solution; (5) after mixing the product of step (3) with polyvinyl chloride and ABS engineering plastics, the mixture was heated within a temperature range of 180°C Blending, the blending time is 5 minutes; (6) Di-n-octyltin dilaurate and the mixed solution are mixed within a ...

Embodiment 2

[0020] A preparation method of antibacterial plastics for toys, the specific steps are: (1) weighing 45 parts of polyvinyl chloride, 25 parts of ABS engineering plastics, 5 parts of di-n-octyltin dilaurate, 2 parts of calcium phosphate, 2 parts of methyl hydrojasmonate, 4 parts of polysaccharides, 3 parts of lauryltrimethylammonium chloride, 5 parts of ceolone, 5 parts of betaine; (2) lauryltrimethylammonium chloride and betaine after cleaning, crushing, grinding, drying, and sieving to obtain powder; (3) mix the powder with bamboo leaf ketone evenly, add polysaccharide, and stir while adding; (4) mix calcium phosphate and Methyl dihydrojasmonate was mixed at 55°C and stirred for 15 minutes to obtain a mixed solution; (5) after mixing the resultant of step (3) with polyvinyl chloride and ABS engineering plastics uniformly, within the temperature range of 250°C Blending, the blending time is 10 minutes; (6) Di-n-octyltin dilaurate and the mixed solution are mixed within a tempe...

Embodiment 3

[0022] A preparation method of antibacterial plastics for toys, the specific steps are: (1) Weigh 40 parts of polyvinyl chloride, 20 parts of ABS engineering plastics, 3 parts of di-n-octyltin dilaurate, 1 part of calcium phosphate, and two parts by weight. 0.8 parts of methyl hydrojasmonate, 2 parts of polysaccharides, 2.2 parts of lauryltrimethylammonium chloride, 4 parts of ketone, 2 parts of betaine; (2) Lauryltrimethylammonium chloride and betaine after cleaning, crushing, grinding, drying, and sieving to obtain powder; (3) mix the powder with bamboo leaf ketone evenly, add polysaccharide, and stir while adding; (4) mix calcium phosphate and Methyl dihydrojasmonate was mixed at 42°C and stirred for 12 minutes to obtain a mixed solution; (5) after mixing the product of step (3) with polyvinyl chloride and ABS engineering plastics, the Blending, the blending time is 6 minutes; (6) Di-n-octyltin dilaurate and the mixed solution are mixed within a temperature range of 85 ° C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com