A kind of emulsion of dimer acid modified epoxy acrylic resin and preparation method thereof

A technology of epoxy acrylic and epoxy resin, applied in the field of Pickering emulsion, can solve problems such as crack resistance, poor impact resistance, and brittle cured products, and achieve the effects of controlling production costs, reducing impact, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Preparation of dimer acid modified epoxy acrylic resin emulsion

[0038] (1) Preparation of dimer acid modified epoxy resin

[0039] Add 23.52g of epoxy resin, 16.80g of dimer acid, and 0.04g of tetrabutylammonium bromide into the four-necked flask, heat up under the condition of nitrogen, and react at 120°C for about 8 hours, and the acid value is lower than 1mgKOH / g Finish the reaction and cool to room temperature.

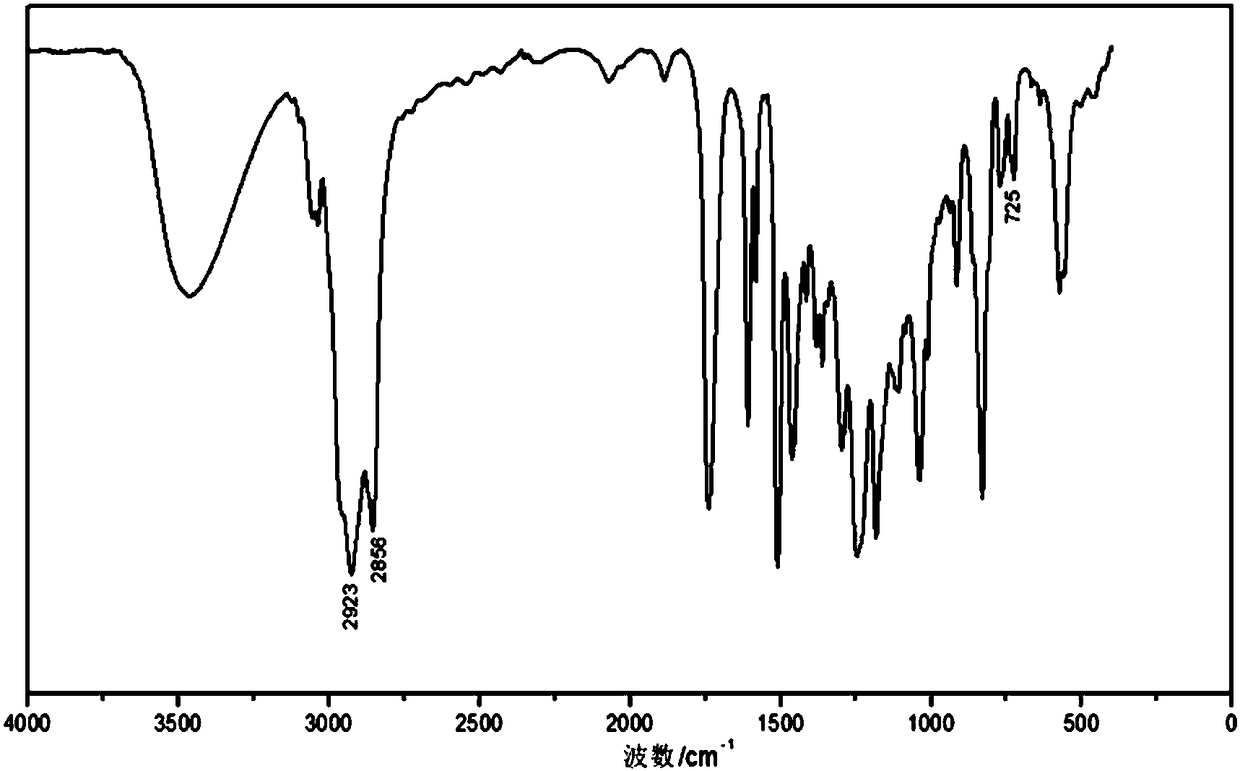

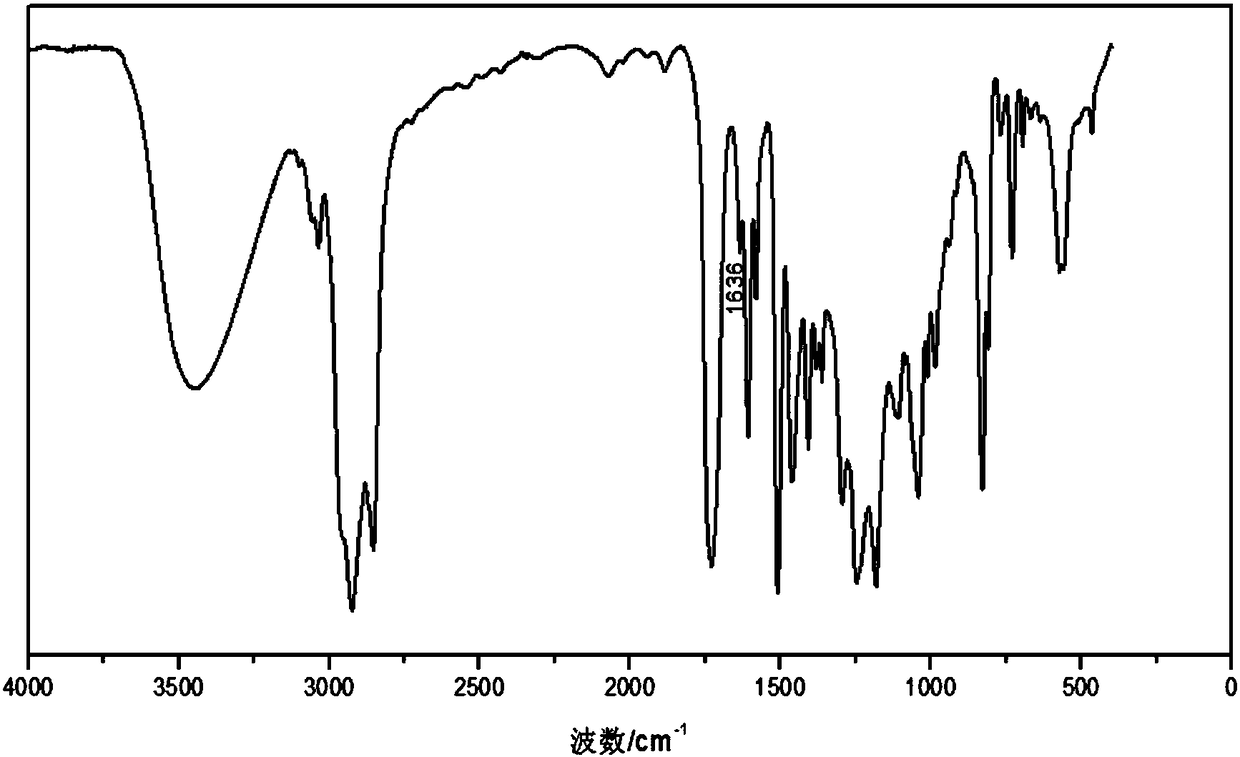

[0040] (2) Preparation of acrylic acid modified hybrid resin

[0041] Put the mixed solution of 4.32g of acrylic acid, 0.28g of tetrabutylammonium bromide, and 0.028g of hydroquinone into the four-necked flask containing the hybrid resin obtained in the above steps, and heat and stir at 80°C for about 6 hours. When the acid value is lower than 1mgKOH / g, the reaction is terminated, and the modified epoxy resin is obtained after cooling to room temperature.

[0042] (3) Preparation of modified epoxy resin emulsion by phase inversion method ...

Embodiment 2

[0045] Embodiment 2: the preparation of dimer acid modified epoxy acrylic resin emulsion

[0046] (1) Preparation of dimer acid modified epoxy resin

[0047] Add 23.52g of epoxy resin, 16.80g of dimer acid, and 0.04g of tetrabutylammonium bromide into the four-necked flask, and heat up under the condition of blowing nitrogen. React at a temperature of 140°C for about 6 hours, and the acid value is lower than 1mgKOH / g to end the reaction, and cool to room temperature.

[0048] (2) Preparation of acrylic acid modified hybrid resin

[0049] Put the mixed solution of 4.32g of acrylic acid, 0.28g of tetrabutylammonium bromide, and 0.028g of hydroquinone into the four-necked flask containing the hybrid resin obtained in the above steps, and heat and stir at 80°C for about 4 hours. When the acid value is lower than 1mgKOH / g, the reaction is terminated, and the modified epoxy resin is obtained after cooling to room temperature.

[0050] (3) Preparation of modified epoxy resin emuls...

Embodiment 3

[0052] Embodiment 3: Preparation of dimer acid modified epoxy acrylic resin emulsion

[0053] (1) Preparation of dimer acid modified epoxy resin

[0054] Add 23.52g of epoxy resin, 16.80g of dimer acid, and 0.04g of tetrabutylammonium bromide into the four-necked flask, and heat up under the condition of blowing nitrogen. React at a temperature of 120°C for about 4 hours, the acid value is lower than 1mgKOH / g to end the reaction, and cool to room temperature.

[0055] (2) Preparation of acrylic acid modified hybrid resin

[0056] Put the mixed solution of 4.32g of acrylic acid, 0.28g of tetrabutylammonium bromide, and 0.028g of hydroquinone into the four-necked flask containing the hybrid resin obtained in the above steps, and heat and stir at 100°C for about 4 hours. When the acid value is lower than 1mgKOH / g, the reaction is terminated, and the modified epoxy resin is obtained after cooling to room temperature.

[0057] (3) Preparation of modified epoxy resin emulsion by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com