Thermal treatment device

A heat treatment device and technology for heating devices, which are applied in heat treatment equipment, quenching devices, manufacturing tools, etc., can solve problems such as the service life of salt media affecting the quenching effect of components, and the failure of salt media to meet the cooling requirements, so as to avoid boiling or quenching. The effect of denaturation, simple structure and uniform heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

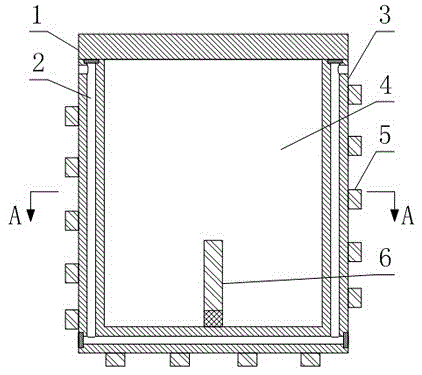

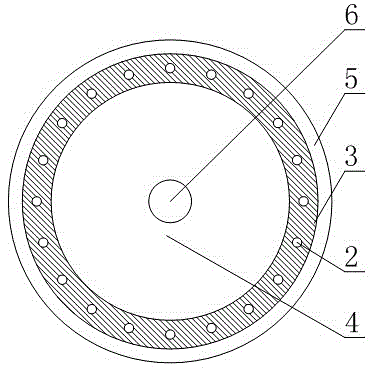

[0021] Such as figure 1 and figure 2 As shown, a heat treatment device includes a bath body 3, the bath body 3 is a barrel-shaped structure provided with a furnace 4, the bath body 3 is also provided with a heating device for heating the furnace 4, and the heating device It includes a mixing electrode 6 arranged in the furnace 4 and an electric heating belt 5 wound on the outside of the side surface and the outside of the bottom surface of the bath body 3 , and a cooling channel 2 is drilled in the tank wall of the bath body 3 .

[0022] In this embodiment, by using the electric heating belt 5 as the heating device, and the heating belt is arranged on the outside of the bath body 3, compared with the existing heating device arranged inside the furnace 4, the heating device is not used in the furnace 4 for salt. The heating medium of the bath is in direct contact, and at the same time, the bath body 3 is used as an intermediate heat transfer object between the heating belt an...

Embodiment 2

[0024] The present embodiment is further limited on the basis of embodiment 1, as figure 1 and figure 2 As shown, as a form of cooling channel 2 that is easy to process, the cooling channel 2 includes two vertical channels arranged on the side of the bath body 3 and a horizontal channel arranged on the bottom surface of the bath body 3, and the two vertical channels pass through the horizontal channel. The channels are connected.

[0025] As a form of cooling flow channel that facilitates uniform temperature drop, there is more than one cooling flow channel.

[0026] In order to further optimize the above-mentioned uniform cooling effect, the vertical channels are evenly distributed in a ring shape on the bath body 3 .

[0027] In order to facilitate the temperature detection or control of the heating medium in this structure, a temperature sensor is also arranged in the furnace 4 .

[0028] In order to reduce or avoid oxidation of the heating medium during the working pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com