Preparation method for phosphatized stainless steel electrolyzed water catalytic material

A catalytic material, stainless steel technology, applied in circuits, fuel cells, electrical components, etc., can solve the problems of harsh conditions, complex preparation process, and low mechanical strength of nickel foam, and achieve the effect of easy industrialization, good catalytic performance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

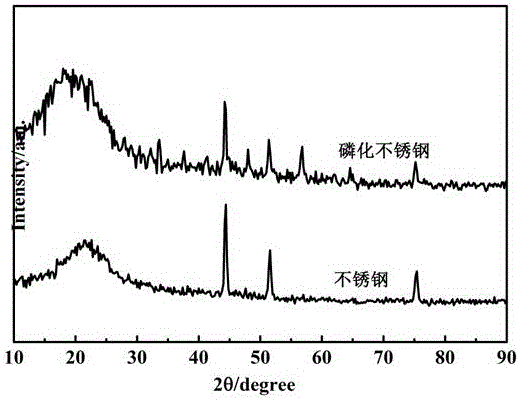

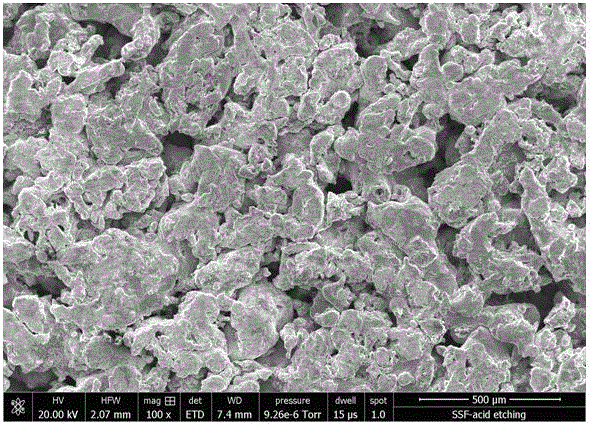

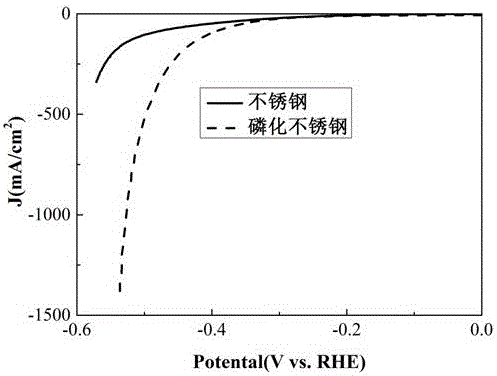

[0019] A kind of preparation method of water splitting electrocatalyst is as follows: 1cm 2 The stainless steel foam sheet and 2 grams of sodium hypophosphite were respectively placed in a tube furnace, and calcined at 500 ° C for 2 hours under the protection of argon to obtain a phosphating stainless steel foam electrolysis water catalyst;

[0020] The obtained phosphating stainless steel foam was used as the working electrode, the platinum electrode was used as the counter electrode, and the silver / silver chloride electrode was used as the reference electrode, and a three-electrode system was used for electrochemical analysis in 1M KOH solution. The results show that the electrocatalytic material has good hydrogen and oxygen production performance, and the hydrogen and oxygen production can reach 10mA / cm 2 The overpotentials required for the current density are 206mv and 298mv, respectively;

Embodiment 2

[0022] Method is with embodiment 1: with 1cm 2 The stainless steel foam sheet and 2 grams of sodium hypophosphite were respectively placed in a tube furnace, and calcined at 600 ° C for 2 hours under the protection of argon to obtain a phosphating stainless steel foam electrolysis water catalyst;

[0023] The results showed that hydrogen and oxygen production reached 10mA / cm 2 The overpotentials required for the current density are 236mv and 313mv, respectively;

Embodiment 3

[0025] Method is with embodiment 1: with 1cm 2 The stainless steel foam sheet and 2 grams of sodium hypophosphite were respectively placed in a tube furnace, and calcined at 400 ° C for 2 hours under the protection of argon to obtain a phosphating stainless steel foam electrolysis water catalyst;

[0026] The results showed that hydrogen and oxygen production reached 10mA / cm 2 The overpotentials required for the current density are 242mv and 323mv, respectively;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com