Solid state laser

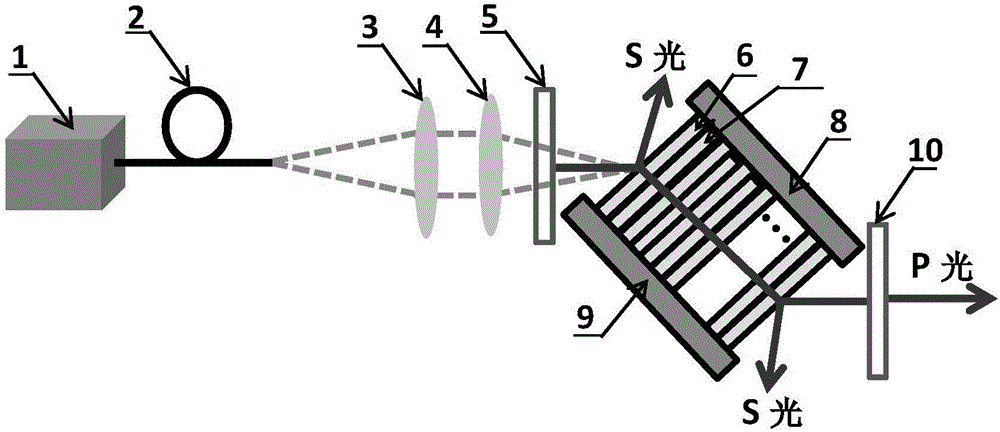

A solid-state laser, laser gain technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of complex optical system structure, thermal effect problems, serious thermal effects, etc., to achieve high beam quality, high power, improved The effect of overall thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

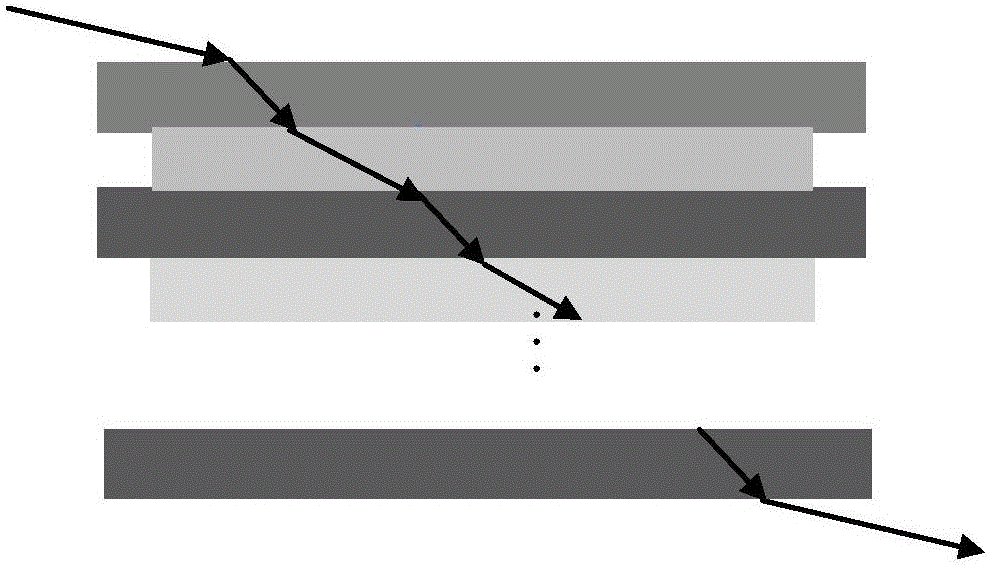

[0039]Embodiment 1 of the present invention, the pump source adopts a laser diode with a wavelength of 808 nanometers, the output power is greater than 40 watts, the laser line width is 3 nanometers, and the pump pigtail is a single-clad 400-micron multimode fiber with a numerical aperture of 0.22 The optical fiber, the first coupling lens and the second coupling lens are double-convex lenses of K9 glass, the focal length is 50mm, and the numerical aperture is 0.3; the laser crystal is Nd:YVO4, the thickness is 200 microns, together with 5 layers of crystals, high thermal conductivity The material is 6H-SiC (one of the configurations of SiC), the thickness is 500 microns, and the number of layers is 6 layers. The cross-bonding forms a periodic compound gain medium structure; the pump end cavity mirror and the output cavity mirror are made of K9 glass The two color mirrors form a laser resonant cavity. The pump end cavity mirror increases the reflection of the pump light and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com