Soilless seedling raising matrix and preparing method thereof

A soilless seedling raising and substrate technology, applied in the agricultural field, can solve the problems of poor permeability, low porosity, poor quality of seedling raising, easy hardening, etc., so as to avoid excessive permeability, promote growth and nutrient absorption, Effect of Improving Seedling Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

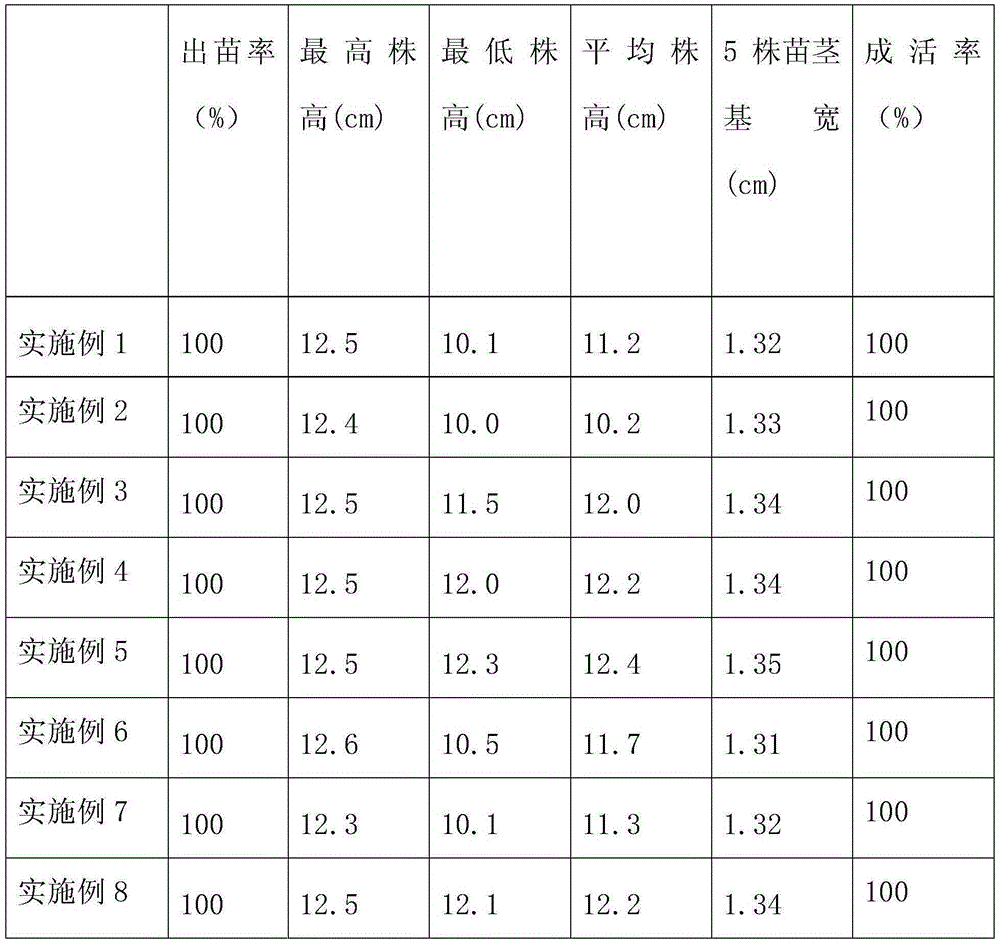

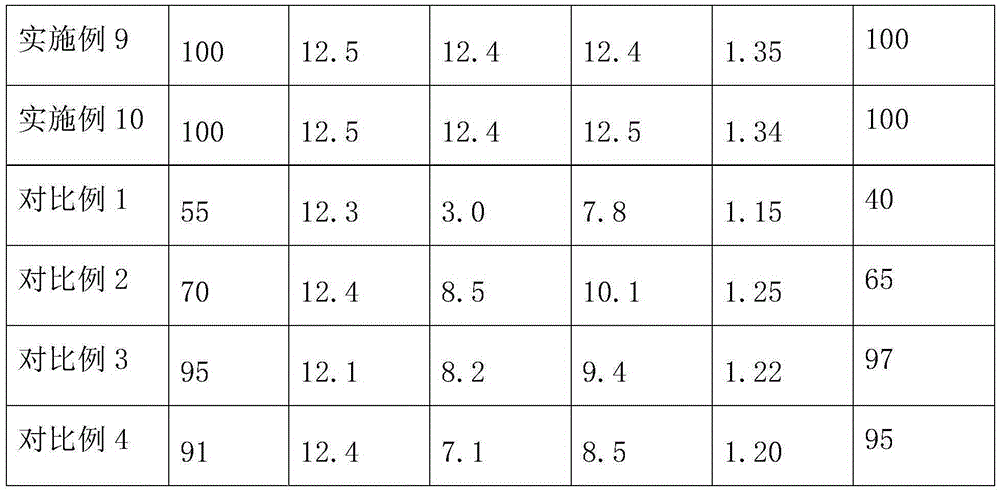

Examples

Embodiment 1

[0035] The soilless seedling raising substrate described in this example is composed of the following raw materials: 40 kg of fermented rice straw, 20 kg of peanut shell chips, 1 kg of nutrient, 20 kg of binder and 10 kg of water retaining agent. The particle size of the fermented rice straw is 0.5 mm, the particle size of the peanut shell chips is 5 mm, the nutrient is a root-stimulating agent, the binder is starch, and the water-retaining agent is puffed mica.

[0036] The fermented rice straw is prepared by the following method, which specifically includes the following steps:

[0037] (1) get dry straw and be ground into straw chips, set aside;

[0038] (2) Add a putrefaction agent to the straw clippings, the mass ratio of the putrefaction agent to the straw clippings is 0.5:100000, soak and dilute the putrefaction agent with clear water before adding, soaking time is 10h , the volume ratio of the putrefaction agent to the added water is 4:100000, and the diluted putrefac...

Embodiment 2

[0043] The soilless seedling raising substrate described in this example is composed of the following raw materials: 50 kg of fermented rice straw, 10 kg of peanut shell chips, 2 kg of nutrient, 10 kg of binder and 20 kg of water retaining agent. Wherein, the particle size of the fermented rice straw is 5 mm, the particle size of the peanut shell chips is 0.5 mm, the binder is attapulgite, the water-retaining agent is zeolite powder, and the nutritional agent is composed of the following parts by weight: Composition of raw materials: 8 parts of monoammonium phosphate, 1 part of urea, 7 parts of potassium chloride, 1 part of thiophanate-methyl, 0.1 part of imidacloprid, 0.17 part of rooting and seedling strengthening agent and 0.2 part of uniconazole.

[0044] The fermented rice straw is prepared by the following method, which specifically includes the following steps:

[0045] (1) get dry straw and be ground into straw chips, set aside;

[0046] (2) Add a putrefaction agent t...

Embodiment 3

[0051] The soilless seedling raising substrate described in this example is composed of the following raw materials: 45 kg of fermented rice straw, 15 kg of peanut shell chips, 1.5 kg of nutrient, 15 kg of binder and 15 kg of water retaining agent. Wherein, the particle size of the fermented rice straw is 1 mm, the binder is bentonite, the water retaining agent is activated carbon powder, the particle size of the peanut shell chips is 4 mm, and the nutrient consists of the following parts by weight: Composition of raw materials: 4 parts of monoammonium phosphate, 3 parts of urea, 3 parts of potassium chloride, 7 parts of bentonite, 0.1 part of thiophanate-methyl, 1 part of imidacloprid, 0.01 part of rooting agent and 0.2 part of uniconazole.

[0052] The fermented rice straw is prepared by the following method, which specifically includes the following steps:

[0053] (1) get dry straw and be ground into straw chips, set aside;

[0054] (2) Add a putrefaction agent to the str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com