Synergistic tiamulin fumarate premixing agent and preparation method thereof

A technology of tiamulin fumarate and premix, which is applied in the field of synergistic tiamulin fumarate premix and its preparation, can solve the problems of affecting the growth of livestock and poultry, increasing the cost of treatment, and the emergence of drug-resistant bacteria. Improve breathing difficulties, enhance antibacterial efficacy, and improve ventilation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

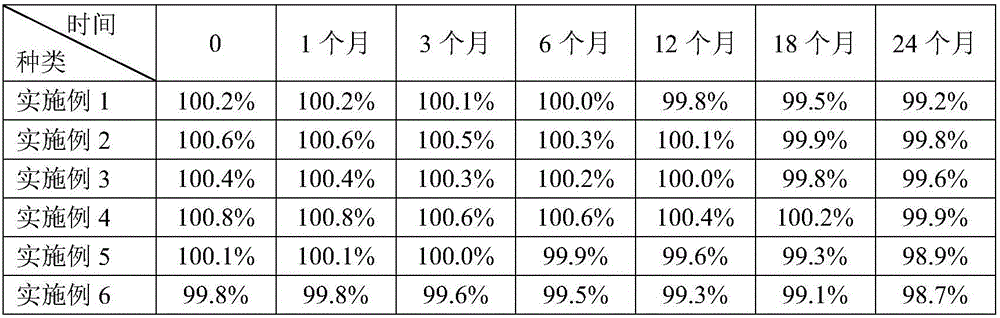

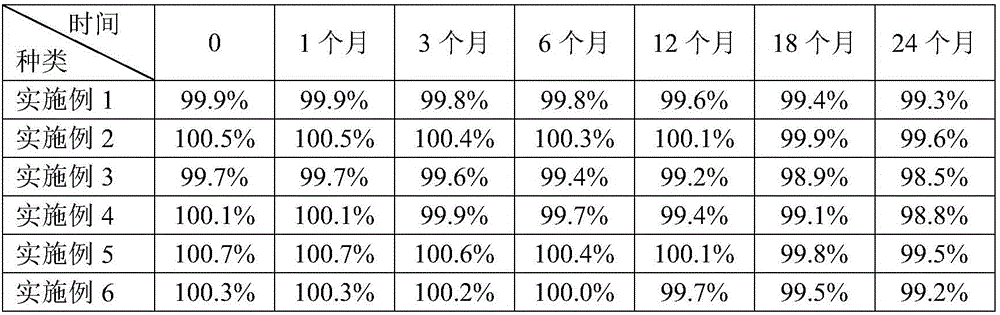

Embodiment 1

[0017] A synergistic tiamulin fumarate premix is prepared from the following raw materials in percentage by weight: 80% tiamulin fumarate, 0.5% alpha-asarone, 10% starch and 9.5% corncob powder.

[0018] A preparation method of a synergistic tiamulin fumarate premix: first weigh the tiamulin fumarate, α-asarone, and corncob powder according to weight percentage, grind them through a 120-mesh sieve respectively, and grind the starch through a 120-mesh sieve. The starch slurry with a concentration of 10% is made by the slurry method, and then the tiamulin fumarate, α-asarone and corn cob powder are mixed evenly, and the starch slurry is added to make a soft material, which is granulated with a 18-mesh nylon sieve and baked. After drying, pass through a 12-mesh sieve for granulation.

Embodiment 2

[0020] A synergistic tiamulin fumarate premix is prepared by mixing the following raw materials in percentage by weight: 10% tiamulin fumarate, 4% alpha-asarone, 2% starch and 84% corncob powder.

[0021] A preparation method of a synergistic tiamulin fumarate premix: first weigh the tiamulin fumarate, α-asarone, and corncob powder according to weight percentage, grind them through a 120-mesh sieve respectively, and grind the starch through a 120-mesh sieve. The starch slurry with a concentration of 10% is made by the slurry method, and then the tiamulin fumarate, α-asarone and corncob powder are mixed evenly, and the starch slurry is added to make a soft material, which is granulated with a 18-mesh nylon sieve and baked. After drying, pass through a 12-mesh sieve for granulation.

Embodiment 3

[0023] A synergistic tiamulin fumarate premix is prepared from the following raw materials in percentage by weight: 45% tiamulin fumarate, 3% alpha-asarone, 6% starch and 46% corncob powder.

[0024] A preparation method of a synergistic tiamulin fumarate premix: first weigh the tiamulin fumarate, α-asarone, and corncob powder according to weight percentage, grind them through a 120-mesh sieve respectively, and grind the starch through a 120-mesh sieve. The starch slurry with a concentration of 10% is made by the slurry method, and then the tiamulin fumarate, α-asarone and corn cob powder are mixed evenly, and the starch slurry is added to make a soft material, which is granulated with a 18-mesh nylon sieve and baked. After drying, pass through a 12-mesh sieve for granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com