Method for achieving simultaneous desulfurization, denitration and mercury removal in injection mode

A desulfurization, denitrification and injection technology, which is applied in the field of desulfurization, denitrification and mercury removal, can solve the problems of unsatisfactory treatment effect of integrated treatment technology, and achieve the effect of avoiding corrosion and loss, and pure discharge atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

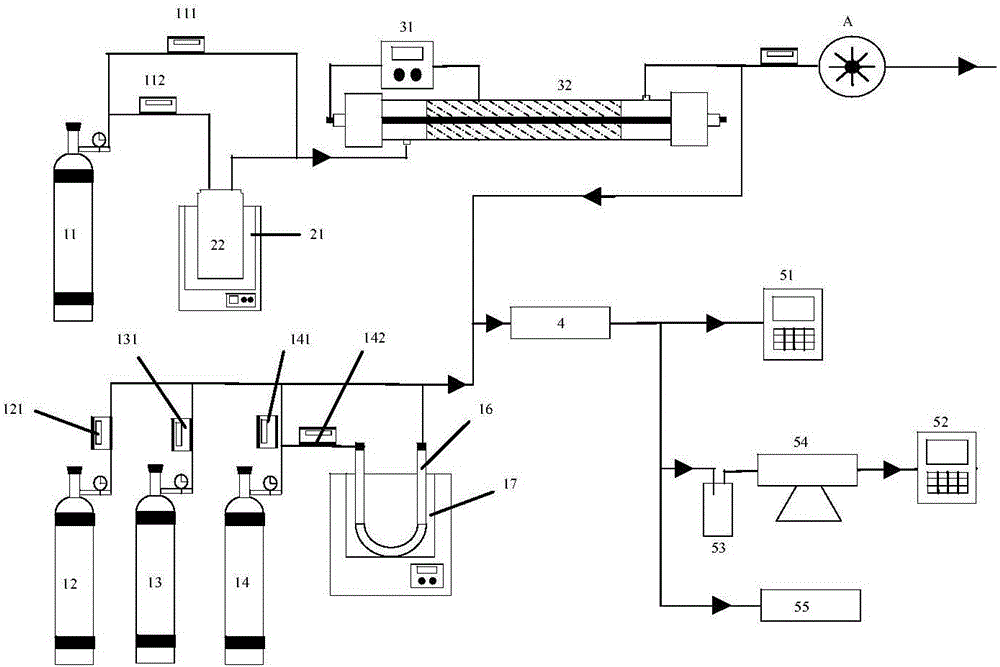

[0030] see figure 1 , the present invention adopts an injection-type simultaneous desulfurization, denitrification and mercury removal device, and the injection-type simultaneous desulfurization, denitrification and mercury removal device is provided with a coal-fired flue gas generation unit, a water vapor generation unit 2, a plasma generation unit, a gas mixing unit and a detection unit.

[0031] The coal-fired flue gas generating unit is provided with O 2 Gas cylinder 11, NO gas cylinder 12, SO 2 Cylinder 13, N 2 Cylinder 14, Hg 0 Permeation pipe 16 and flue gas generation constant temperature water bath 17;

[0032] The water vapor generating unit is composed of a water vapor generating constant temperature water bath 21, a gas washing bottle 22 and connecting pipelines;

[0033] The plasma generating unit is provided with a high-voltage power supply 31 and a plasma reactor 32;

[0034] The gas mixing unit is composed of a gas mixing chamber 4 (a columnar glass conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com