Catalyst and preparation method thereof and method for producing hydrogen by photocatalytically decomposing water

A catalyst and photocatalysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc. Simple, high rate of hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

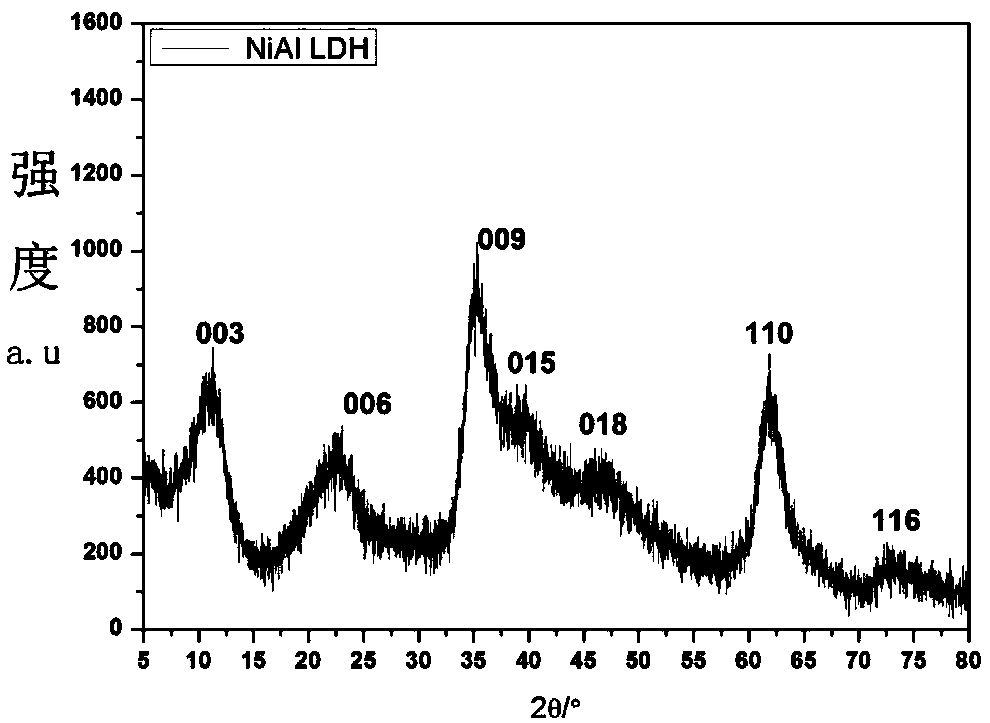

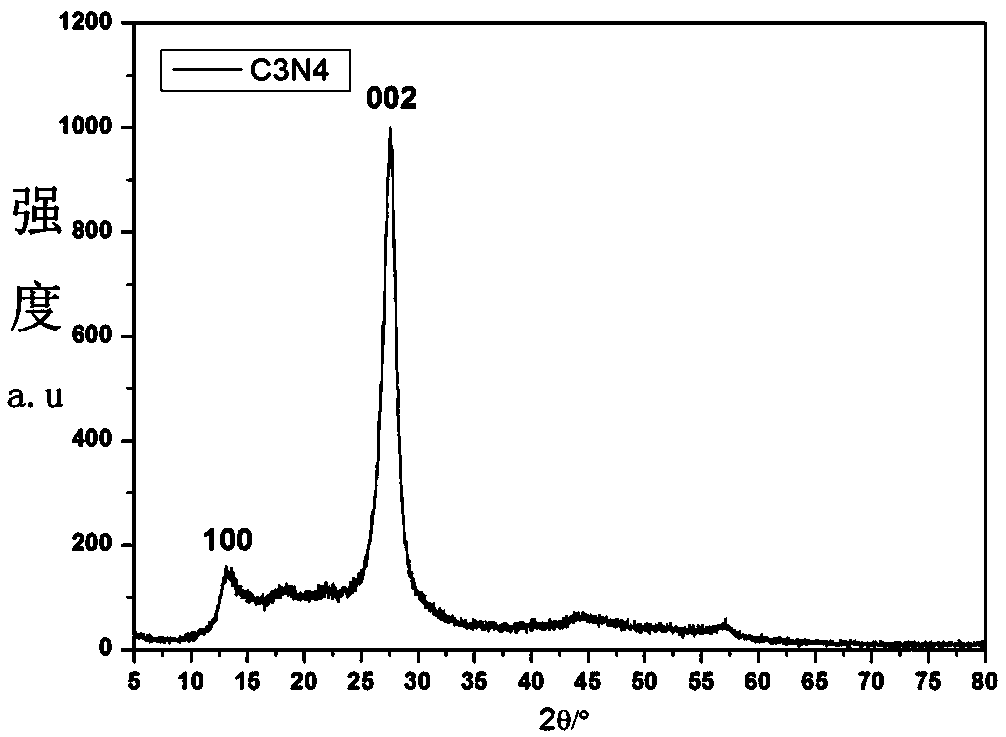

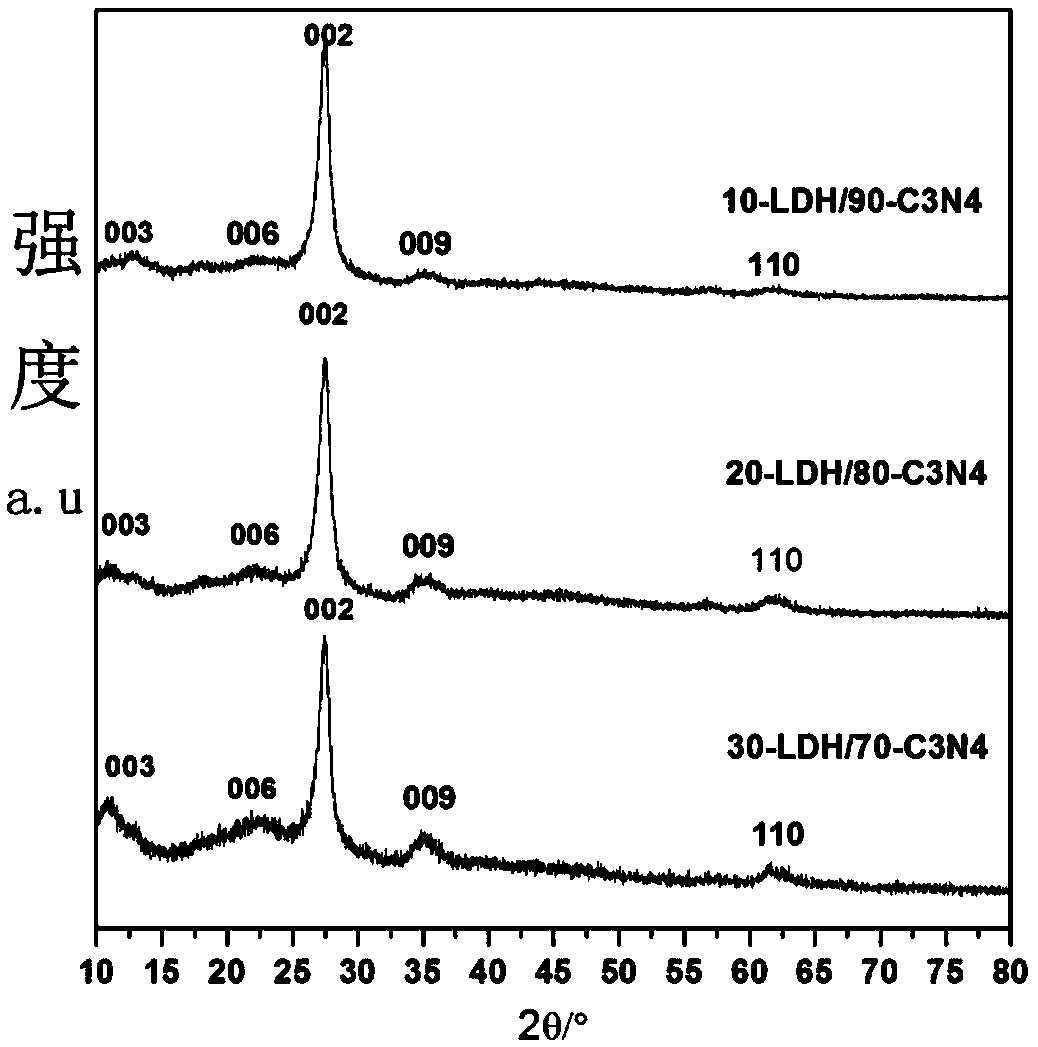

[0035] Catalyst of the present invention is in C 3 N 4 The complex formed by doping Ni-Al-LDH is expressed as Ni-Al-LDH / C 3 N 4 . Ni-Al-LDH and C in the composite 3 N 4 The mass ratio of is preferably 1:(1.5-19). After doping, the composite formed by the recombination of the two materials, but still maintains the characteristics of the layered structure, in which Ni-Al-LDH is interspersed in the C 3 N 4 In the layered structure, it has absorption ability to light (ultraviolet light and visible light) of 0nm-780nm, and the absorption ability is very high, so that the efficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com