A Tool Holder Shrinking System Based on Electromagnetic Induction

An electromagnetic induction and induction heating coil technology, applied in induction heating devices, induction heating, electric heating devices, etc., can solve the problem of high price, and achieve the effects of large market value, easy realization, optimal heating and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

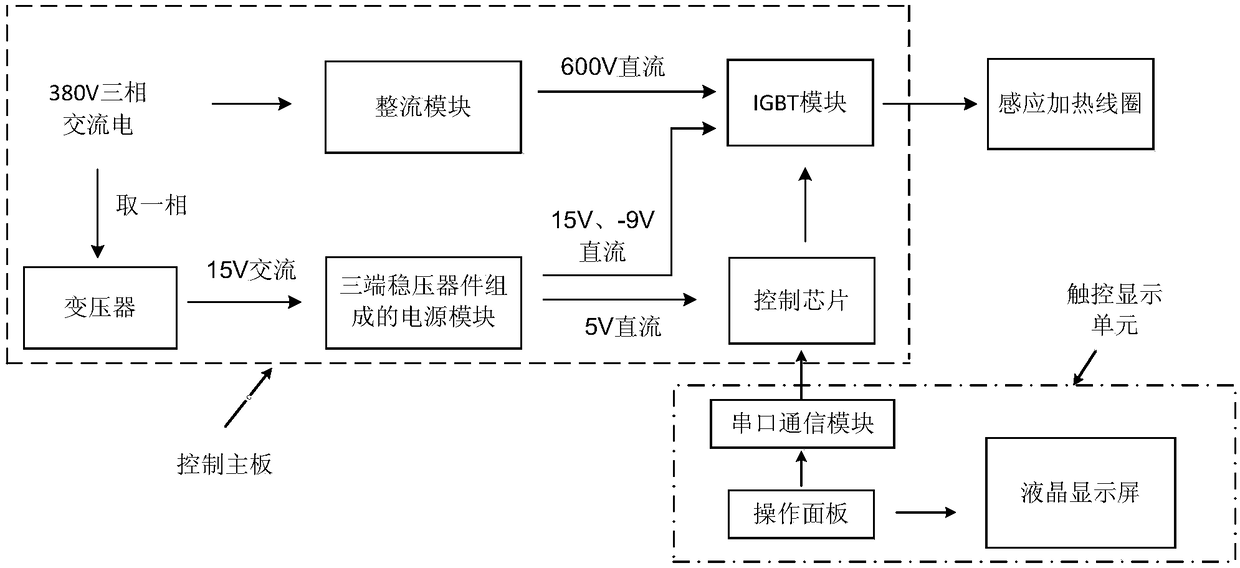

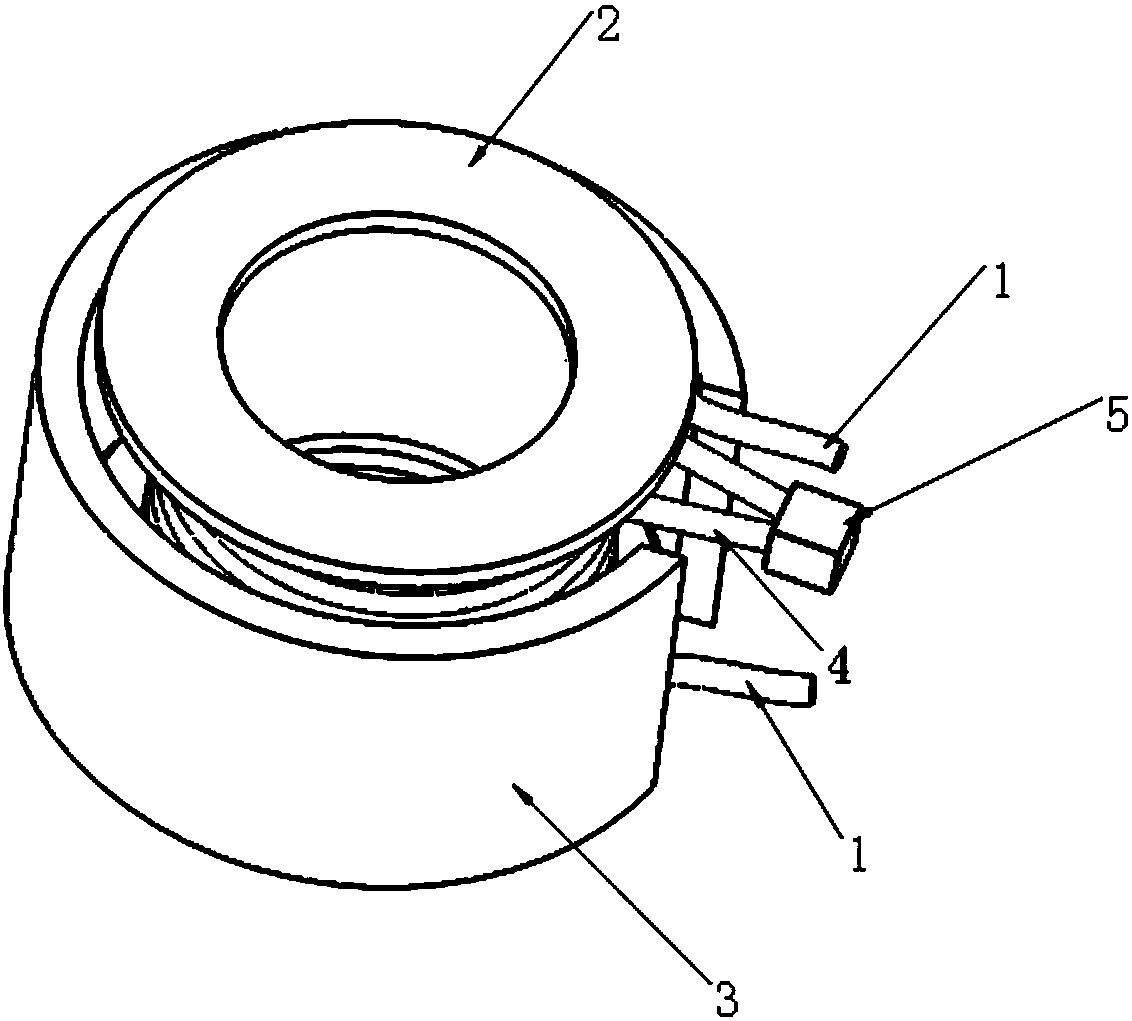

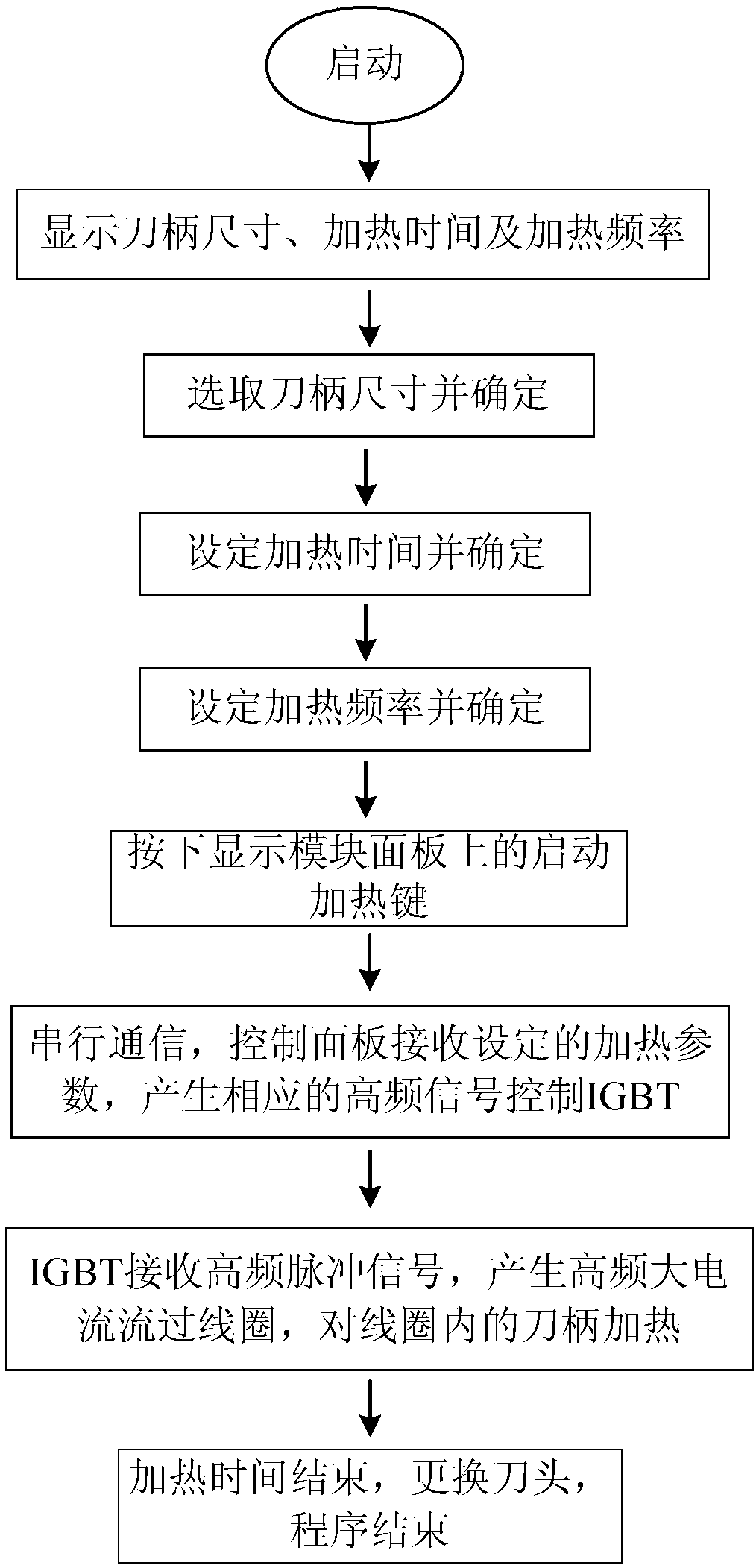

[0028] Such as figure 1 As shown, the tool handle thermal charging system of the present invention is composed of an induction heating coil, a touch display unit and a control board. The control mainboard includes a rectifier module, a transformer, a power supply module, an IGBT module and a control chip; the touch display unit includes a liquid crystal display, an operation panel and a serial communication module.

[0029] In the control board, one phase of the 380V three-phase AC power enters the rectifier module, and the 380V three-phase AC power at the input end is rectified into 600V DC for supply to the IGBT module. The rectifier module in this embodiment includes an AC voltage input terminal and a DC voltage output terminal, has less wiring, high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com