Feeding and discharging system and method for electronic waste pyrolysis

A technology of electronic waste, feeding and discharging, applied in the field of feeding and discharging systems, can solve the problems of unable to meet the requirements of continuous feeding of large-sized solid particles, expensive construction and operation costs, complex gas product process processing, etc., and achieve remarkable energy-saving effects , high degree of automation and stable atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

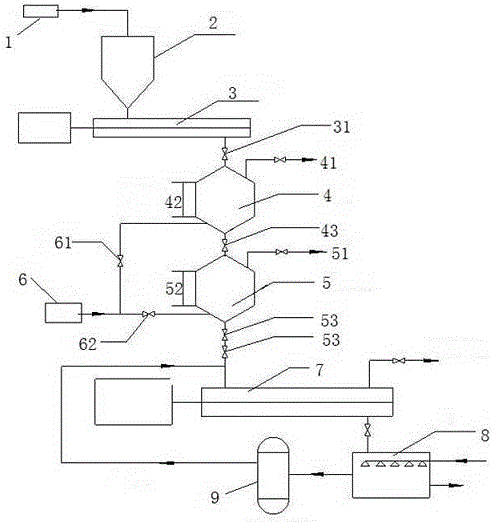

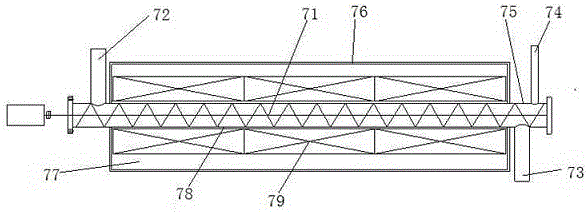

[0033] The invention proposes a material feeding and discharging system for pyrolysis of electronic waste. According to an embodiment of the present invention, figure 1 It is a structural schematic diagram of the feed-in and discharge system of electronic waste pyrolysis according to an embodiment of the present invention, referring to figure 1 As shown, the system includes: a feeding device 3, a feed bin 4, an intermediate storage tank 5, a reactor 7, a cooling chamber 8 and a gas-water separator 9, wherein the feeding device is located above the feed bin, and The feed port of the silo is connected, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com