System and method for feeding and discharging materials for coal pyrolysis

A technology for feeding and discharging and coal pyrolysis, which is applied in the field of feeding and discharging systems, can solve the problems of inability to meet the requirements of continuous feeding of large-sized solid particles, expensive construction and operation costs, and complicated processing of gas products, and achieves energy-saving effects. Remarkable, high degree of automation, stable atmosphere effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

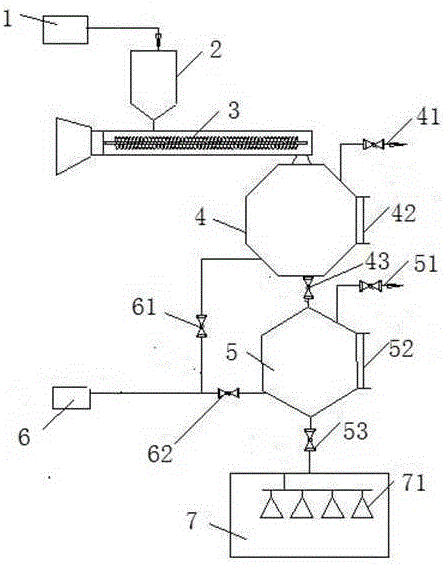

[0053] When the system is in normal operation, the solid particle material with a particle size range of 3-6mm is transported to the hopper above the screw feeding device through the mechanical device, and then the material in the hopper is transported to the silo through the screw feeding device. At the same time, open the cut-off valve on the pipeline, introduce gas into the silo for replacement, blow off the air that comes in with the material, and exhaust the exhaust gas from the vent pipe on the silo. Then, through the connecting pipeline and the cut-off valve on it, the gas is introduced into the intermediate storage tank to replace the intermediate storage tank. After the replacement is completed, when the material level in the silo reaches 1 / 2 of the silo, that is, the 1 / 2 of the material level gauge, the shut-off valve between the silo and the intermediate storage tank is opened, and the material level drops to 1 / 2 of the material level gauge. 1 / 4 of the position mete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com