Solid hydrolysis hydrogen production material

A technology for hydrogen production and water-absorbing materials by hydrolysis, which is applied in the production of hydrogen, metal hydrides, inorganic chemistry, etc., can solve the problems of inconvenient storage and use of sodium borohydride solution, capacity loss, etc., achieve obvious effects, improve uniformity, Effect of increasing hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Nickel chloride hexahydrate (NiCl2 ·6H 2 O) 0.12g was dissolved in 5mL deionized water, and 0.05g of melamine sponge (apparent volume about 7cm 3 ) cut into 0.2×0.2×5cm 3 strips, the above NiCl 2 The solution is absorbed, and the water is evaporated to dryness at 200°C in a drying oven, and the NiCl 2 Dehydration to anhydrous NiCl 2 , the sponge is brownish-yellow as a whole.

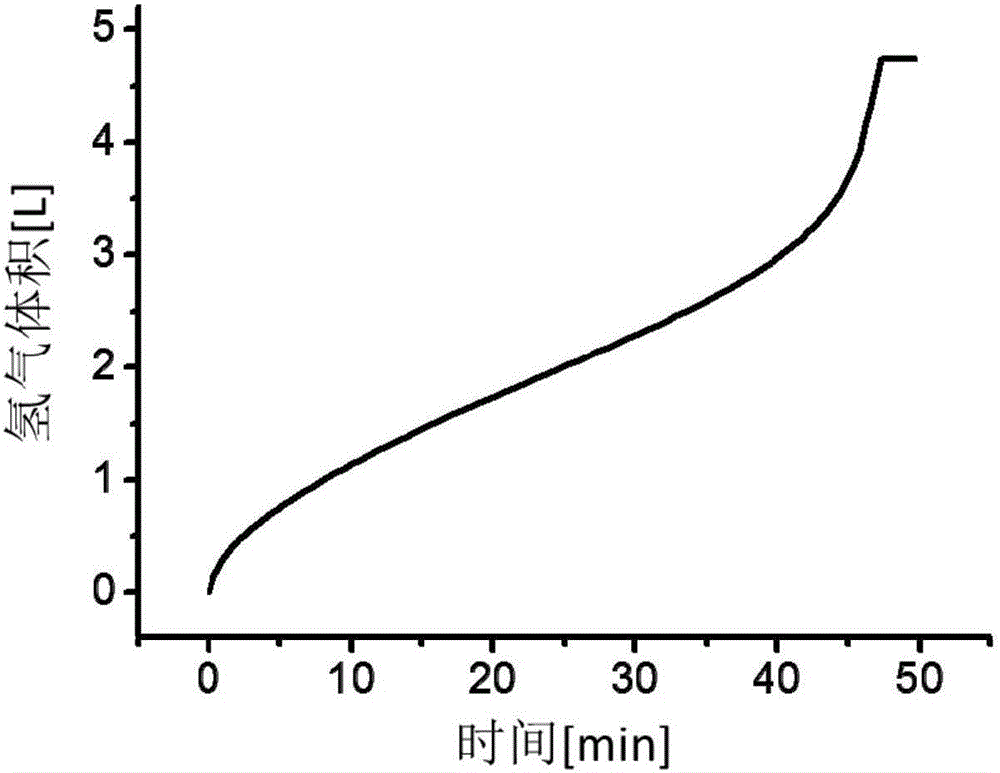

[0036] NaBH 4 2.0g with NiCl loaded above 2 The sponges are packaged together in a plastic reaction tube with an inner diameter of 1.0 cm and a height of 10 cm. First, the sponge strips are vertically placed in the tube, and then NaBH 4 Powder, NaBH 4 The powder automatically falls into the gap of the plastic tube. Add 8mL of deionized water at 25°C, the system generates hydrogen quickly and uniformly, and generates H within 48min. 2 4.8L, see figure 1 , there was no flowing liquid in the container after the reaction, and the sponge was black.

Embodiment 2

[0038] Cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) 1.5g dissolved in 10mL deionized water, melamine sponge 0.07g (approximate volume 10cm 3 ) cut into 1mm 3 For pellets, the above CoCl 2 The solution is absorbed, and the water is evaporated to dryness at 200°C in a dry box, and the CoCl 2 Dehydration to anhydrous CoCl 2 , the overall color of the sponge is blue.

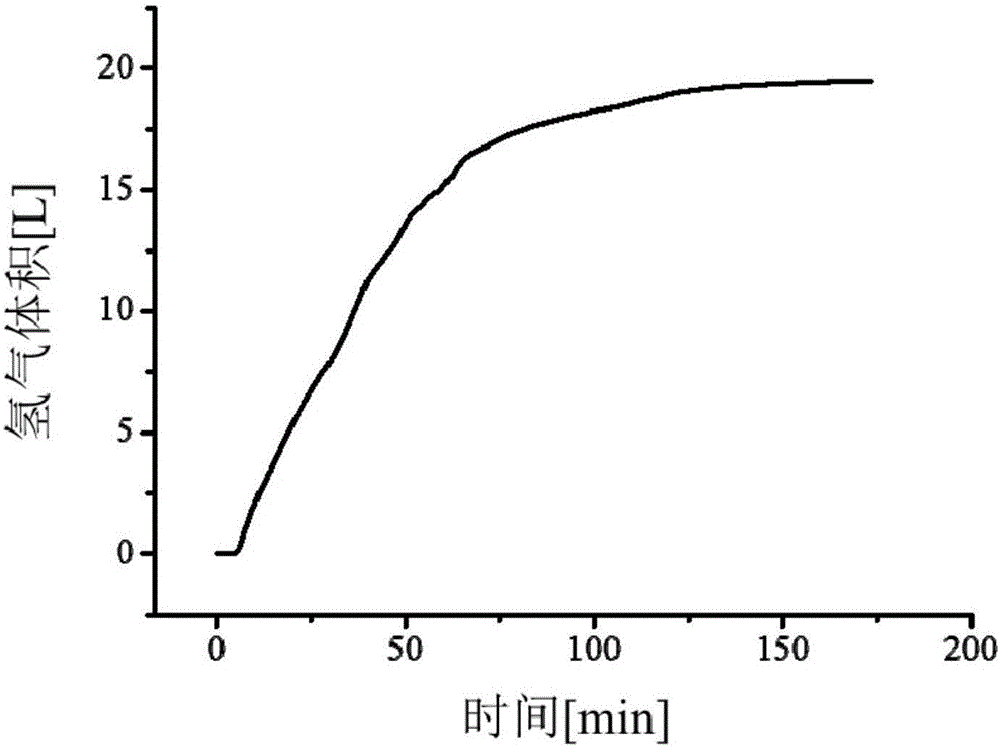

[0039] Load the above with CoCl 2 Sponge pellets with NaBH 4 Mix the ground powder, put it into a glass reactor with an inner diameter of 2.5cm and a height of 12cm, slowly add tap water at a rate of 0.15mL / min through a peristaltic pump, and the system will generate hydrogen gas evenly. The first 60min will generate 15.0L of hydrogen gas, with an average rate of 250mL / min , producing a total of 19.0L of hydrogen, see figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydraulic conductivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com