Preparation method of single-component high-ortho-position-content thermosetting phenolic resin used for extrusion

A phenolic resin, high ortho position technology, applied in the field of preparation of single-component high ortho position thermosetting phenolic resin for pultrusion, can solve the problems of limited application of phenolic resin, complex molding process, short storage period, etc., to promote the development of the industry , The preparation method is simple and effective, and the curing speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

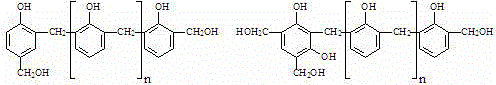

Image

Examples

Embodiment 1

[0030] free phenol Solid content gel time calorific value viscosity ortho-pair ratio GY-03 11.55% 82.65% 104s 24 MJ / kg 2775 mPa.S 1.89

Embodiment 2

[0032] free phenol Solid content gel time calorific value viscosity ortho-pair ratio GY-07 12.14% 76.56% 74s 26 MJ / kg 2435 mPa.S 1.80

Embodiment 3

[0034] free phenol Solid content gel time calorific value viscosity ortho-pair ratio GY-06 11.97% 78.25% 85s 26 MJ / kg 2034 mPa.S 1.84

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com