Ho<3+>/Yb<3+>/Gd<3+> co-doped zinc oxide up-conversion luminescent material and preparation method thereof

A luminescent material and co-doping technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of inability to do high concentration, complex preparation process, low luminous intensity, etc., and achieve environmental friendliness, simple synthesis process, and luminescence strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] To achieve the above object, the present invention provides a Ho 3+ / Yb 3+ / Gd 3+ Co-doped ZnO up-conversion luminescent material, the chemical composition is: Zn 1-x-y-z Ho x Yb y Gd z O, where Ho 3+ is the active ion, Yb 3+ is the sensitizer, x is Ho 3+ Mole percentage of doping, y is Yb 3+ Mole percent of doping, z is Gd 3+ The molar percentage of doping, and x+y+z=9mol%, promptly x=1mol%, y=5mol%, z=3mol%, preparation steps are as follows:

[0027] Step 1, prepare zinc acetate solution, get the Zn(Ac) of 6.585g 2 , dissolved in 30ml of deionized water, stirred until it was fully dissolved into a colorless and transparent solution ①.

[0028] Step 2, preparing rare earth nitrates. Weigh the corresponding rare earth oxide Ho in proportion Zn:Ho:Yb:Gd=0.91:0.01:0.05:0.03 2 o 3 , Yb 2 o 3 and Gd 2 o 3 , mix evenly, dissolve in dilute nitric acid solution, heat and stir at 40°C-60°C, and evaporate the solution to dryness at 50°C-70°C after fully reactin...

Embodiment 2

[0035] In this embodiment, Ho 3+ / Yb 3+ / Gd 3+ The chemical composition and preparation method of the co-doped ZnO up-conversion luminescent material are the same as in Example 1, except that x+y+z=6mol%, z=0.

Embodiment 3

[0037] In this embodiment, Ho 3+ / Yb 3+ / Gd 3+ The chemical composition and preparation method of the co-doped ZnO up-conversion luminescent material are the same as in Example 1, except that x+y+z=7mol%, z=1mol%.

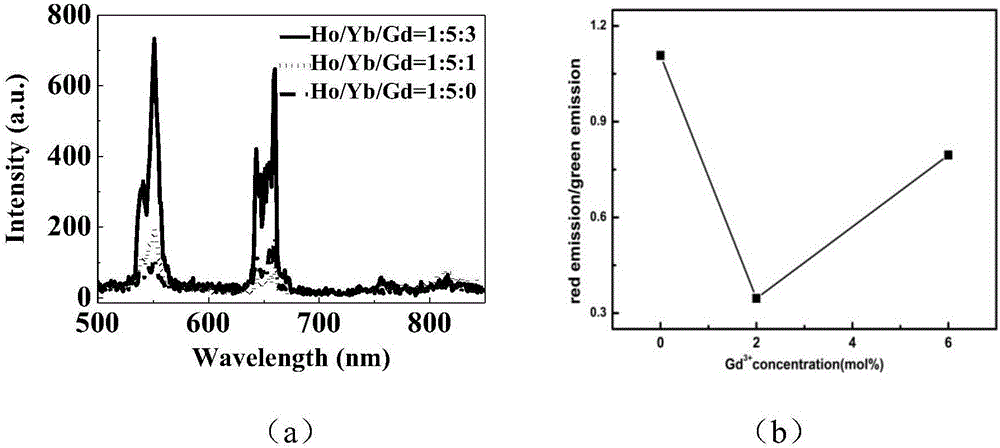

[0038] Carry out X-ray powder diffraction pattern analysis, SEM picture and the up-conversion emission spectrum that the sample obtains under 980nmLD excitation to the sample that above embodiment makes and analyze, and the result is as follows:

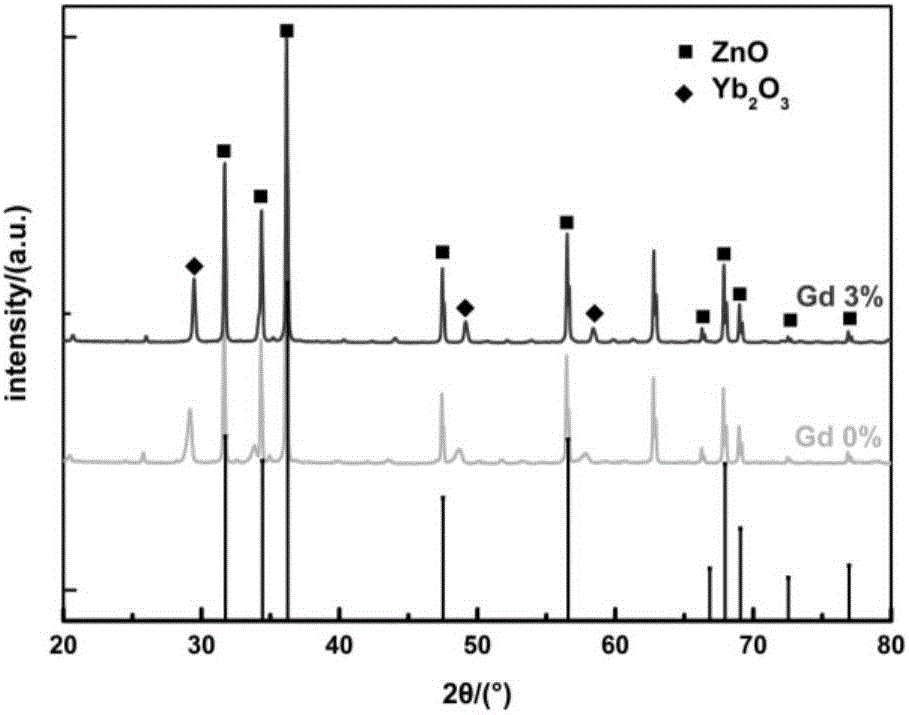

[0039] figure 1 It is Example 1 sample Zn 0.91 Ho 0.01 Yb 0.05 Gd 0.03 X-ray powder diffraction pattern of O. It can be seen that the main crystal phase is ZnO, and individual Yb 2 o 3 peak. Table 1 lists the lattice constants of rare earth doped ZnO and pure ZnO. It is obvious from the data in the table that with the doping of rare earth ions, the lattice constant becomes larger, which may be caused by the partial entry of rare earth ions into the lattice of ZnO and replacement of Zn atoms.

[0040] Table 1 Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com