A kind of recombinant Bacillus subtilis with high chondroitin production and its application

A technology of Bacillus subtilis and chondroitin, applied in the field of bioengineering, can solve problems such as high cost, low yield, and inability to meet market demand, and achieve the effect of increasing production and sufficient supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

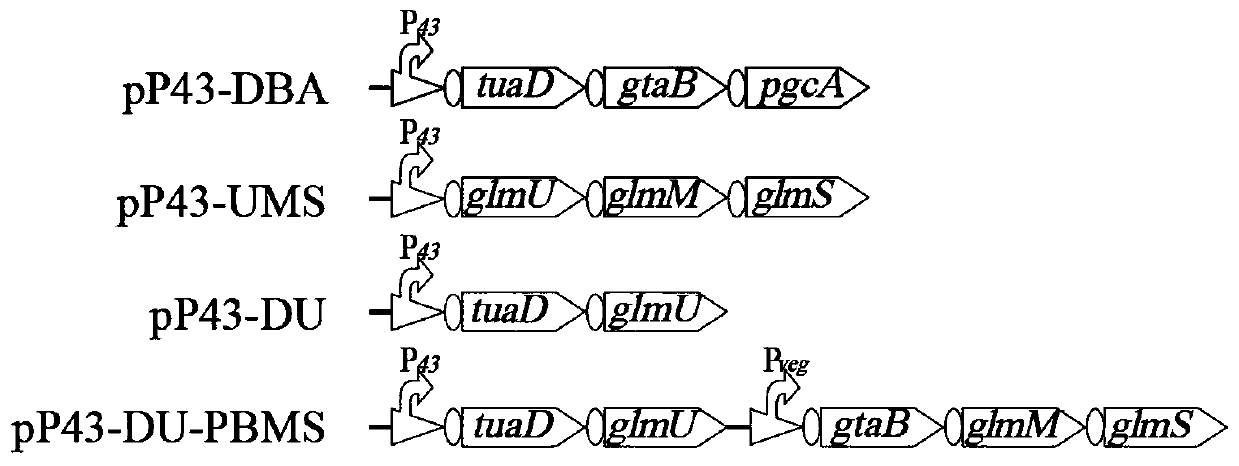

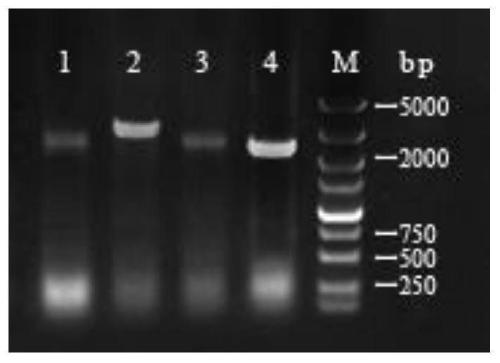

[0028] Construction of the recombinant Bacillus subtilis of embodiment 1 co-expression pathway gene

[0029] First prepare B.subtilis E168C competent cells, the required reagent is inorganic salt mother solution (g / L): K 2 HPO 4 140, KH 2 PO 4 60, (NH 4 ) 2 SO 4 20, (Na 3 C 6 h 5 o 7 2H 2 O)10, MgSO4 7H 2 O2; GMI solution (every 100mL): inorganic salt mother solution 9.6mL, 20% glucose 2.5mL, 5% hydrolyzed casein 0.4mL, 10% yeast juice 1mL; GMII solution (every 100mL): inorganic salt mother solution 9.7mL, 20 % glucose 2.5mL, 5% hydrolyzed casein 0.08mL, 10% yeast juice 0.04mL, 1M MgCl 2 0.25mL, 1M CaCl 2 0.05mL. Inoculate a single colony of B.subtilis E168C in 5mL of GMI solution, culture at 30°C and 125rpm for 16h, transfer 2mL of culture solution to 18mL of GMI solution, culture at 37°C and 200rpm for 3.5h, then transfer 10mL of culture solution to 90mL of GMII solution , cultured at 37°C and 200rpm for 90min, centrifuged at 4°C and 5000g for 10min to collect...

Embodiment 2

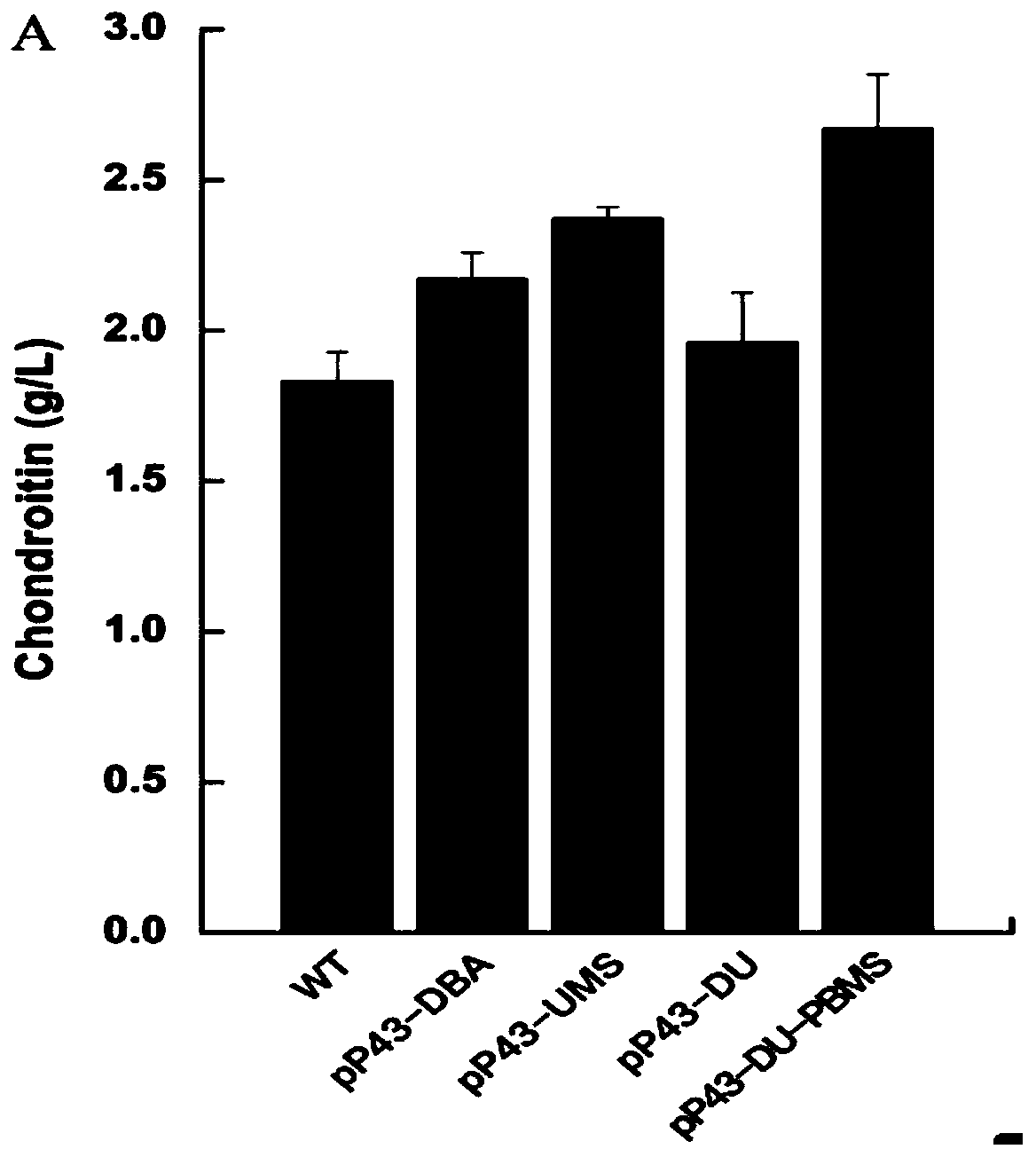

[0040] Shake flask fermentation of embodiment 2 recombinant bacillus subtilis

[0041] Single colonies of the 4 strains of recombinant Bacillus subtilis constructed above and the control bacterium B. subtilis E168C were picked respectively, inoculated in the seed medium, and cultured overnight at 200 rpm at 37°C for 16 hours. Be 10% inoculum by volume ratio and transfer in 25mL fermentation medium (250mL shaking flask), fermentation medium is: 20g / L yeast powder, 50g / L sucrose, potassium sulfate 3.9g / L, magnesium sulfate 1.5g / L, 50mM phosphate buffer, pH 7.0, in which 50μg / mL kanamycin should be added to the culture medium of recombinant bacteria. Culture at 200rpm at 37°C for 54h, and add xylose mother liquor 2h after inoculation to make the final concentration 20g / L for induction.

[0042] After the fermentation liquid sampled in shake flask culture was centrifuged at 10000g for 5min, add 3 times the volume of absolute ethanol to the supernatant, mix well and place it at 4...

Embodiment 3

[0047] 3L tank fed-batch culture of the recombinant Bacillus subtilis B.subtilis E168C / pP43-DU-PBMS of embodiment 3

[0048] Inoculate a single colony of recombinant bacteria into 150mL seed medium, cultivate at 37°C and 200r / min for 16h, and transfer the seed culture solution to a 3L fermenter containing 1.35L fermentation medium with an inoculum volume of 10% by volume. And add 50 μg / mL kanamycin. Add xylose solution 2h after inoculation to make the final concentration 20g / L for induction. Use 5M NaOH solution to control pH to 7.0, temperature to 37°C, stirring speed to 600r / min within 8h after inoculation, 800r / min after 8h, and ventilation to 2.0vvm. The feeding material liquid is 800g / L sucrose mother liquor, and when the sucrose concentration in the fermentation liquid is lower than 5g / L, start feeding, and maintain the residual sugar concentration at 0-5g / L. During 8-12h, the flow rate was 7.5, 7.5, 15, 10g / L / h, respectively, and thereafter the flow rate of 5g / L / h was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com