Method for preparing molybdenum-containing additive and carbon disulfide by vacuum carbothermal reduction of molybdenum concentrate

A molybdenum additive and carbon disulfide technology, applied in the direction of carbon disulfide, carbon sulfur compounds, etc., can solve the problems of large pollution, high production cost, polluted gas, etc., and achieve the effects of short process, easy operation and control, and reduced treatment and emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Make the particle size less than 0.15mm, MoS 2 (mass fraction) be 94% molybdenum concentrate and the active carbon powder of grain size less than 0.1mm according to the actual molybdenum disulfide content in the molybdenum concentrate and active carbon powder molar ratio 1:1.51 batching, and the powder sample total mass is 8g, fully Mix evenly to obtain evenly mixed powder raw materials.

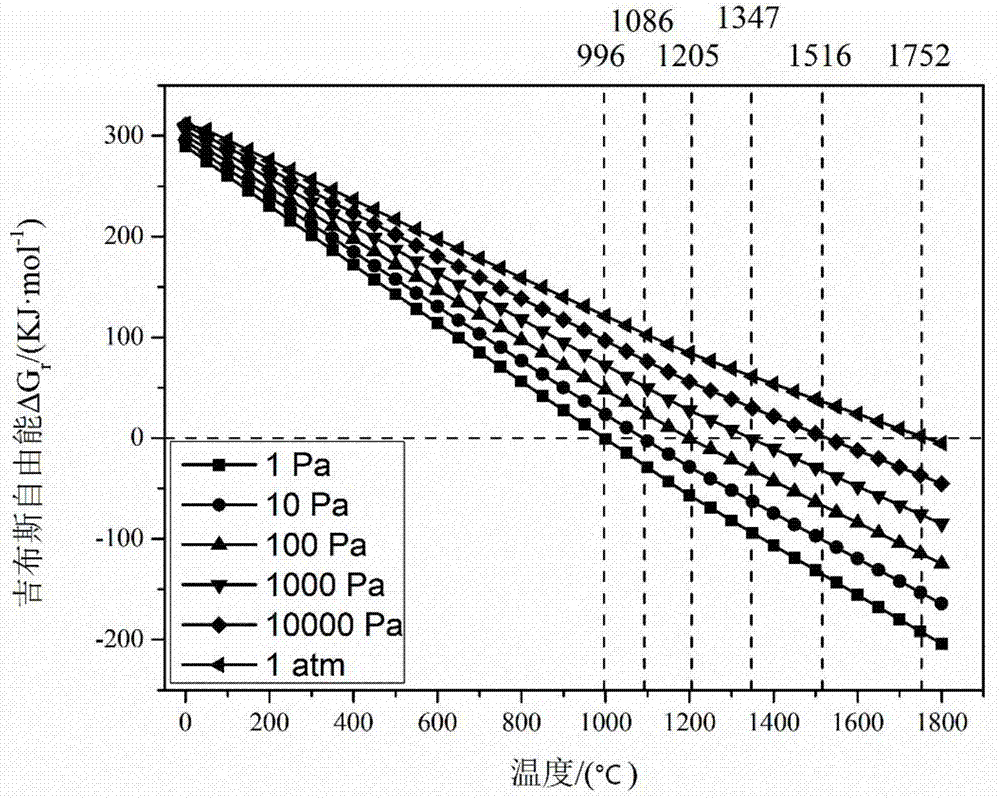

[0027] (3) Put the homogeneously mixed powder raw material obtained in (1) into a high-temperature furnace, heat up and evacuate to a vacuum degree of 10Pa, keep it at a calcination temperature of 1300°C for 4 hours, and collect it at a condensation temperature of 25°C to liquid carbon disulfide.

[0028] (3) After the heat preservation is completed, cool down to room temperature with the furnace to obtain a molybdenum-containing steelmaking additive with a molybdenum content of 90.8% and a sulfur content of less than 0.026%.

Embodiment 2

[0030] (1) Make the particle size less than 0.15mm, MoS 2 (mass fraction) be 94% molybdenum concentrate and the active carbon powder of grain size less than 0.1mm according to the actual molybdenum disulfide content in the molybdenum concentrate and active carbon powder molar ratio 1:1.51 batching, and the powder sample total mass is 8g, fully Mix evenly to obtain evenly mixed powder raw materials.

[0031] (3) Put the homogeneously mixed powder raw material obtained in (1) into a high-temperature furnace, heat up and evacuate to a vacuum degree of 50Pa, keep it at a calcination temperature of 1600°C for 2 hours, and collect it at a condensation temperature of 25°C to liquid carbon disulfide.

[0032] (3) After the heat preservation is completed, cool down to room temperature with the furnace to obtain a molybdenum-containing steelmaking additive, the molybdenum content is 92.1%, and the sulfur content is less than 0.017%.

Embodiment 3

[0034] (1) The particle size is less than 0.05mm, the purity is the analysis pure molybdenum disulfide of 98% and the active carbon powder of particle size is less than 0.1mm according to molar ratio 1:1.5 batching, and the powder sample total mass is 5g, fully mixes evenly, obtains the mixture Uniform powder raw material.

[0035] (3) Put the homogeneously mixed powder raw material obtained in (1) into a high-temperature furnace, heat up and evacuate to a vacuum degree of 10Pa, keep it at a calcination temperature of 1500°C for 2 hours, and collect it at a condensation temperature of 25°C to liquid carbon disulfide.

[0036] (3) After the heat preservation is completed, cool down to room temperature with the furnace to obtain pure molybdenum carbide powder, the purity of molybdenum carbide is 98.7%, and the sulfur content is less than 0.012%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com