Liquid Piston Work Recovery Pulse Tube Refrigeration System and Application of Liquid Piston in it

A liquid piston and pulse tube refrigeration technology, which is applied in refrigeration and liquefaction, refrigerators, lighting and heating equipment, etc., can solve the problems of low efficiency of refrigerators, sound power dissipation, and difficulty in implementation, and achieve long life and high efficiency , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

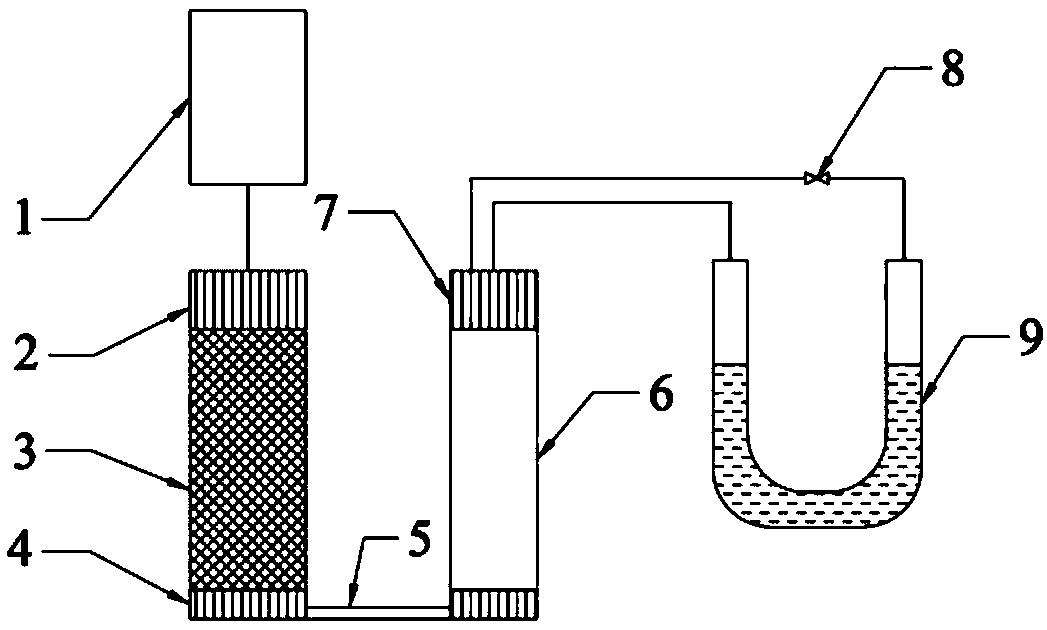

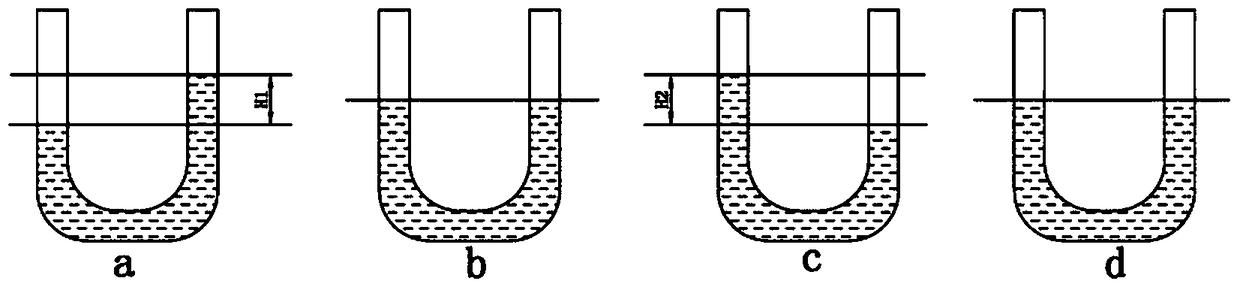

[0032] Such as figure 1 Shows the structure of the liquid piston work recovery type pulse tube refrigeration system in Embodiment 1 of the present invention: it includes a pressure wave generator 1 connected in sequence, for example, a VM type low frequency generator, a room temperature end heat exchanger 2, and a cold accumulator 3. Cold end heat exchanger 4 , pulse tube 6 , pulse tube hot end heat exchanger 7 and phase modulation device 9 . Among them, the pressure wave generator 1 is connected to the heat exchanger 2 at the room temperature end through a connecting pipe, the heat exchanger 4 at the cold end is connected to the pulse tube 6 through the cold head connecting pipe 5, and the heat exchanger 7 at the hot end of the pulse tube is connected to the phase modulation device 9 The inlet of (U-shaped tube filled with liquid mercury) is connected through a connecting pipeline, and the outlet of the phasing device 9 is communicated with the hot end heat exchanger 7 of the...

Embodiment 2

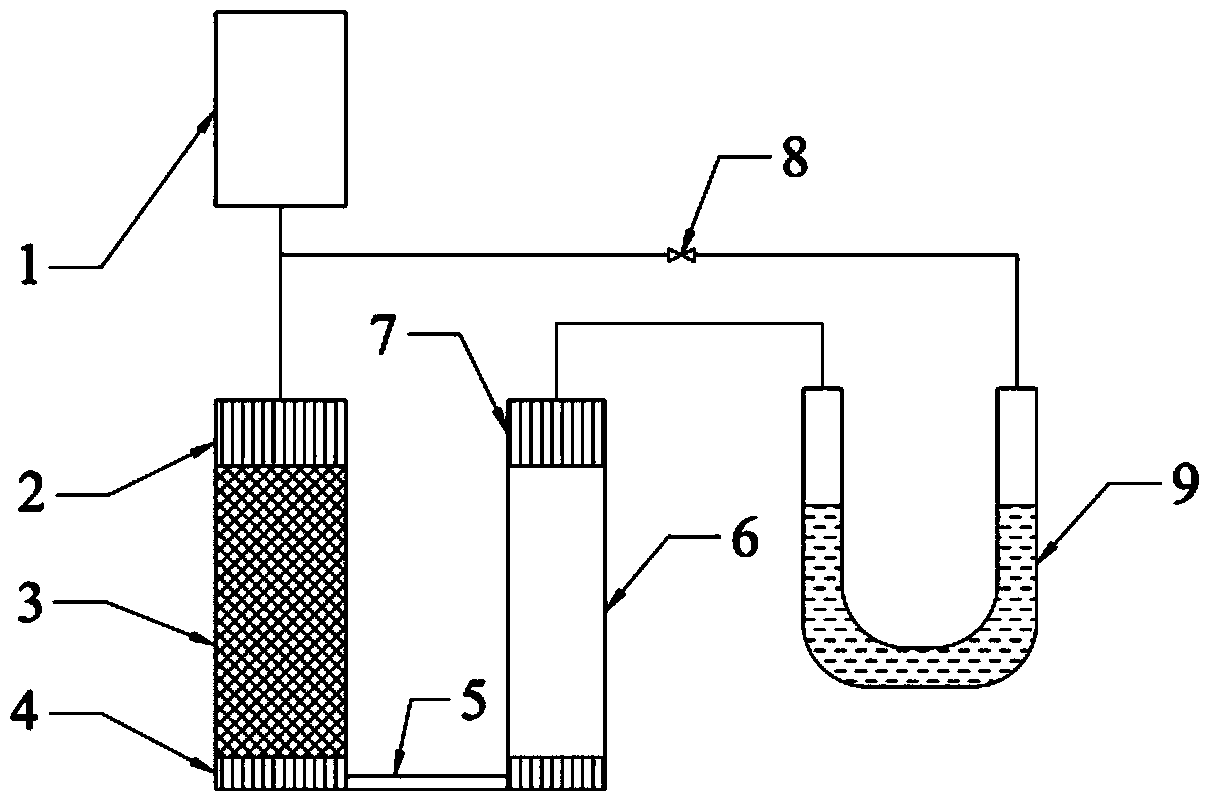

[0035] Such as image 3 The structure of the liquid piston work recovery type pulse tube refrigeration system in Embodiment 2 of the present invention is shown, which is basically the same as in Embodiment 1, the only difference being that the outlet of the phase modulation device 9 passes through the pipeline and the pressure wave generator 1 It is connected to the pipeline between the heat exchangers at the room temperature end, and the pipeline is provided with a resistance adjustment device, such as a regulating valve 8, and the liquid in the U-shaped tube is gallium-indium alloy, and the other conditions remain unchanged. Thereby realizing the recovery of work and the adjustment of the phase of this refrigeration system. During the working process of the pulse tube refrigeration system, controlling the opening of the regulating valve 8 can conveniently adjust the stiffness of the gas working medium above the liquid on the right side of the U-shaped tube, so that the work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com