Method for correcting scanning wavelength mechanical position error of monochromator

A calibration method and monochromator technology, applied in the directions of spectrometry/spectrophotometry/monochromator, instruments, measuring devices, etc., can solve the problems such as the inability to meet the wavelength accuracy of the instrument and the large wavelength scanning error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Sine scanning monochromator mechanical position error correction.

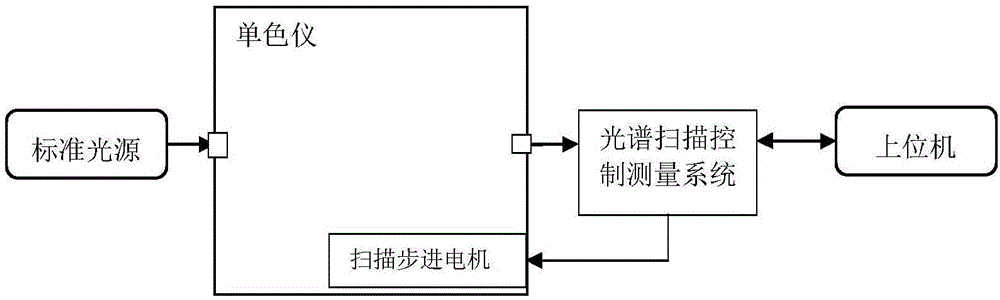

[0077] Build a spectral scanning measurement experimental platform such as image 3 As shown, it consists of a standard light source, a spectral scanning control measurement system and a host computer. The standard light source can be a laser, a mercury lamp, etc., which can provide the corresponding standard wavelength within the spectral range of the monochromator, and fix it at the incident slit of the monochromator or spectrometer splitting system, so that the incident light can fill the monochromator or The collimating mirror of the spectrometer's beam splitting system. The spectral scanning control measurement system is located at the exit slit of the monochromator, and controls the stepper motor to continuously rotate the angle at a certain angular interval, so that the monochromator outputs optical signals of different wavelengths at a certain wavelength interval and range; at the same time, it...

Embodiment 2

[0097] Sine scanning spectrometer mechanical position error correction.

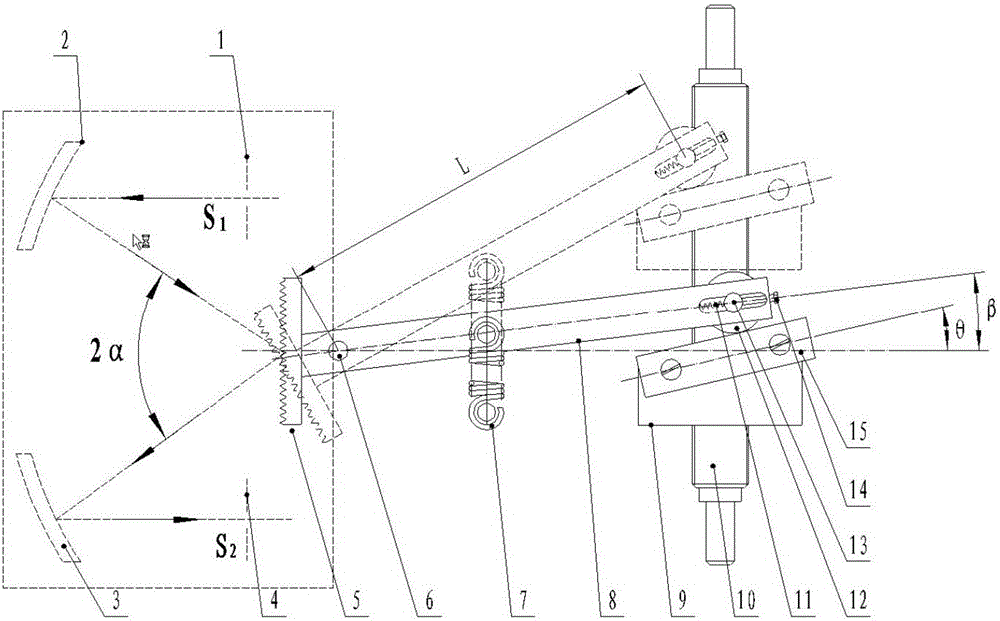

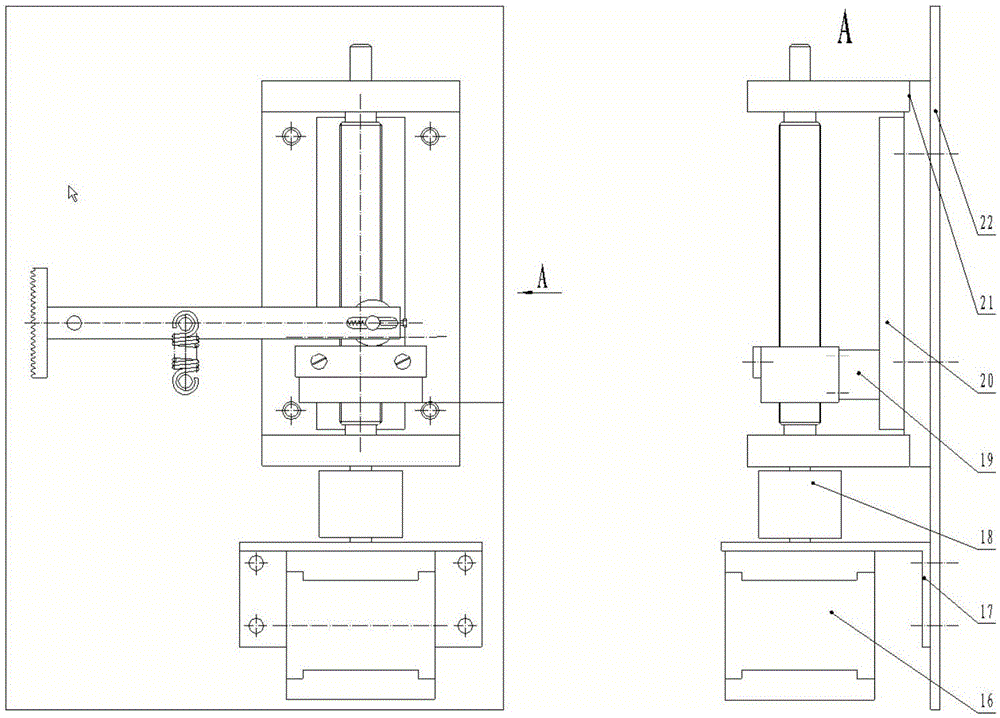

[0098] The structure of the sinusoidal scanning spectrometer is as follows: Figure 5 As shown, the light source and modulator are fixed outside the incident slit of the spectroscopic system (that is, the monochromator), and the relationship between the light source and the incident slit forms an object image, and the detection and control system is respectively connected with the spectroscopic system, sensor module, and host computer. At the same time, the spectroscopic system is connected with the sensor module through the sampler to form a spectrometer. The structure of the spectroscopic system is as figure 1 A sinusoidal sweep mechanism is shown.

[0099] The implementation process of the correction method for the wavelength error caused by the mechanical position error of the spectroscopic scanning mechanism of the sinusoidal scanning spectrometer is as follows: Figure 4 shown, including:

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com