Photovoltaic assembly and photovoltaic power generating system

A photovoltaic module and light-receiving surface technology, which is applied in the field of solar cells, can solve the problems of insufficient bonding force between the single-layer anti-reflection film layer and the substrate, low anti-reflection performance of the anti-reflection film layer, and single control means, so as to reduce internal stress , Reduce insulation, good anti-reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

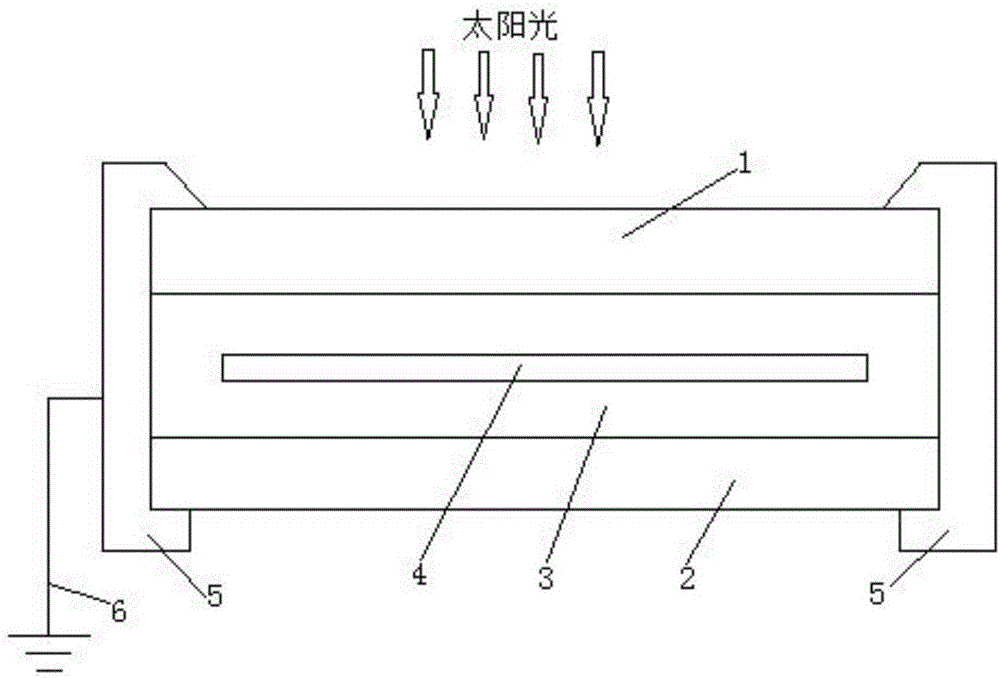

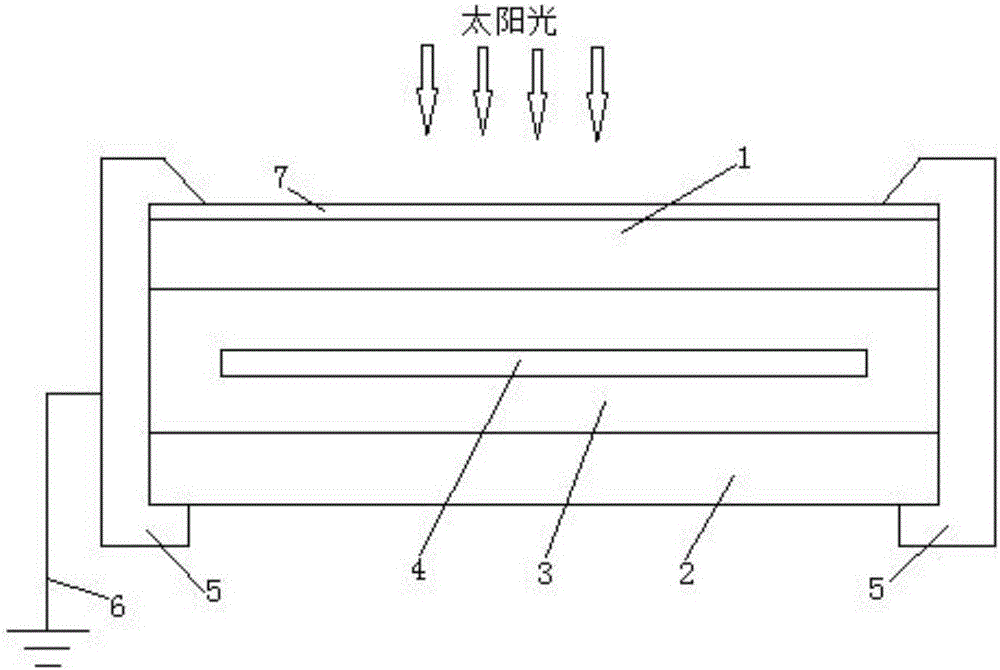

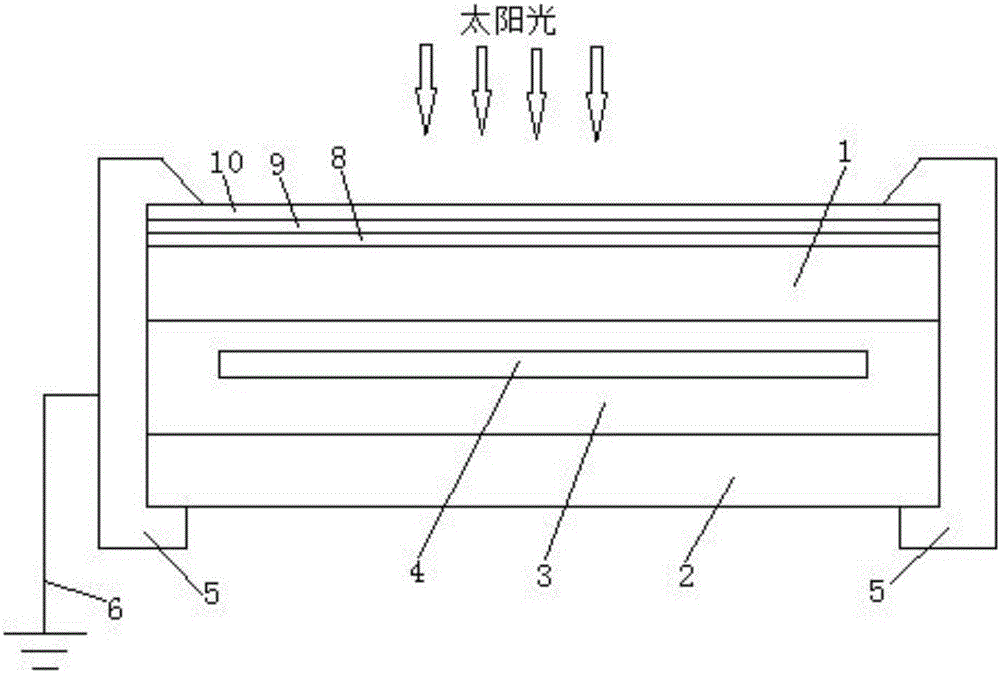

Embodiment 1

[0046] On the surface of a glass substrate with a thickness of 3mm, magnetron sputtering deposits a 20nm silicon oxide film layer as the first barrier layer 8; then, a 10nm Nb-doped titanium dioxide film is deposited on the silicon oxide film layer by magnetron sputtering layer as a conductive film layer 9; then on the Nb-doped titanium dioxide film layer, magnetron sputtering is used to deposit a 110nm silicon oxide film layer as a silicon-containing hydrophilic film layer 10; then the glass deposited with the above film layer is tempered and heat-treated , the tempered heat-treated glass is used as the cover glass 1 of the photovoltaic module, and the film layer on the surface of the tempered glass faces the light-receiving surface of the photovoltaic module, and at the same time, the metal frame 5 of the photovoltaic module is in contact with the Nb-doped titanium dioxide film layer 9 , thus forming the photovoltaic module of the present invention.

Embodiment 2

[0048] On the surface of a glass substrate with a thickness of 4mm, magnetron sputtering deposits a 25nm silicon oxynitride film layer as the first barrier layer 8; then adopts magnetron sputtering to deposit 15nm Ta-doped Titanium dioxide film layer is as conductive film layer 9; Then adopt magnetron sputtering to deposit 110nm silicon oxide film layer on Ta-doped titanium dioxide film layer as silicon-containing hydrophilic film layer 10; Then the glass that will be deposited with above-mentioned film layer is carried out Tempering heat treatment, the glass after tempering heat treatment is used as the cover glass 1 of the photovoltaic module, and the film layer on the surface of the tempered glass faces the light-receiving surface of the photovoltaic module, and at the same time, the metal frame 5 of the photovoltaic module and the Ta-doped titanium dioxide film layer 9 contact, thereby forming the photovoltaic module of the present invention.

Embodiment 3

[0050] On the surface of a glass substrate with a thickness of 4mm, magnetron sputtering deposits a 10nm zirconia film layer as the first barrier layer 8; then, a 5nm W-doped titanium dioxide film is deposited on the zirconia film layer by magnetron sputtering layer as a conductive film layer 9; then on the W-doped titanium dioxide film layer, a 105nm silicon oxide film layer is deposited by magnetron sputtering as a silicon-containing hydrophilic film layer 10; then the glass deposited with the above film layer is tempered and heat-treated , the tempered heat-treated glass is used as the cover glass 1 of the photovoltaic module, and the film layer on the surface of the tempered glass faces the light-receiving surface of the photovoltaic module, and at the same time, the metal frame 5 of the photovoltaic module is in contact with the W-doped titanium dioxide film layer 9 , thus forming the photovoltaic module of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com