Rubber exhaust gas purifying device and method

A waste gas purification device and rubber technology, applied in chemical instruments and methods, separation methods, oxidized water/sewage treatment, etc., can solve problems such as incomplete purification of VOCs, secondary pollution, and use restrictions, and achieve complete removal of harmful substances , strong applicability, and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

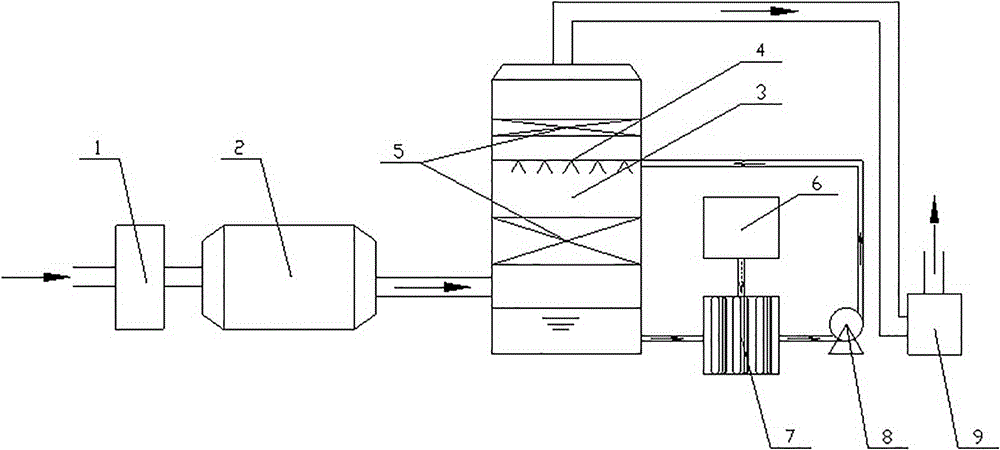

[0025] The technical solution of the present invention will be further technically described below through the embodiments and in conjunction with the accompanying drawings.

[0026] like figure 1 As shown, the present invention includes: filter device 1, photolysis device 2, spray device 3, spray pipe 4, packing layer 5, oxidant storage device 6, ultraviolet light generating device 7, water pump 8, fan 9. The rubber waste gas first passes through the filter device 1 to remove dust such as carbon black and sulfur in the waste gas, ensuring that the subsequent device will not be blocked; the rubber waste gas after dust removal is passed into the photolysis device 2, and the ultraviolet beam can destroy benzene and phenols. , mercaptans, non-methane total hydrocarbons and other pollutants to degrade them into low-molecular substances, CO 2 and H 2 O, to achieve the purpose of preliminary removal of malodorous substances in the rubber waste gas; the spray water generated by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com