Casting coating and preparation method thereof

A coating and raw material technology, applied in the field of casting coating and its preparation, can solve the problems of weakening the precise production advantages of lost foam casting, restricting the development of lost foam casting technology, and many casting quality problems, so as to improve the service life and reduce heat loss. Impact, storage-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

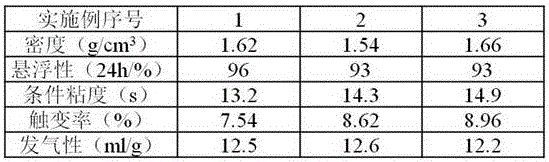

Examples

Embodiment 1

[0052] 1. Ratio of ingredients

[0053] Parts by weight of each composition in component A and component A are:

[0054] 42 parts diatomaceous earth

[0055] 5 parts powdered quartz

[0056] Attapulgite 10 parts

[0057] illite 7 servings

[0058] Wollastonite 16 parts

[0059] 4 parts expanded perlite

[0060] Parts by weight of each composition in component B and component B are:

[0061] 78 parts of ethanol

[0062] 6.5 parts tall oil

[0063] 9 servings of linseed oil fatty acid

[0064] 15 parts phenolic resin

[0065] 0.6 parts of silane coupling agent

[0066] Parts by weight of each composition in component C and component C are:

[0067] Silica airgel 16 parts

[0068] Molybdenum disulfide 2 parts

[0069] Carboxymethylcellulose 15 parts

[0070] Nano titanium dioxide 15 parts.

[0071] Among them, the silica airgel in component C has a specific surface area of 425m 2 / g, the density is 55kg / m 3 raw materials. The particle size of nano titanium dio...

Embodiment 2

[0083] Parts by weight of each composition in component A and component A are:

[0084] Diatomaceous earth 35 parts

[0085] 5 parts powdered quartz

[0086] Attapulgite 12 parts

[0087] illite 8 servings

[0088] Wollastonite 15 parts

[0089] 3 parts expanded perlite

[0090] Parts by weight of each composition in component B and component B are:

[0091] 65 parts of ethanol

[0092] 7 parts tall oil

[0093] 10 servings of linseed oil fatty acid

[0094] 12 parts phenolic resin

[0095] Silane coupling agent 0.5 part

[0096] Parts by weight of each composition in component C and component C are:

[0097] Silica airgel 15 parts

[0098] Molybdenum disulfide 2 parts

[0099] Carboxymethylcellulose 18 parts

[0100] Nano titanium dioxide 18 parts.

[0101] Among them, the silica airgel in component C has a specific surface area of 425m 2 / g, the density is 55kg / m 3 raw materials. The particle size of nano titanium dioxide particles in component C is 50nm. ...

Embodiment 3

[0112] Parts by weight of each composition in component A and component A are:

[0113] 45 parts diatomaceous earth

[0114] 8 parts powdered quartz

[0115] Attapulgite 12 parts

[0116] illite 8 servings

[0117] Wollastonite 18 parts

[0118] 3 parts expanded perlite

[0119] Parts by weight of each composition in component B and component B are:

[0120] 80 parts of ethanol

[0121] 8 parts tall oil

[0122] 10 servings of linseed oil fatty acid

[0123] 15 parts phenolic resin

[0124] 0.6 parts of silane coupling agent

[0125] Parts by weight of each composition in component C and component C are:

[0126] Silica airgel 18 parts

[0127] Molybdenum disulfide 5 parts

[0128] Carboxymethylcellulose 18 parts

[0129] Nano titanium dioxide 18 parts.

[0130] Among them, the silica airgel in component C has a specific surface area of 425m 2 / g, the density is 55kg / m 3 raw materials. The particle size of nano titanium dioxide particles in component C is 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com