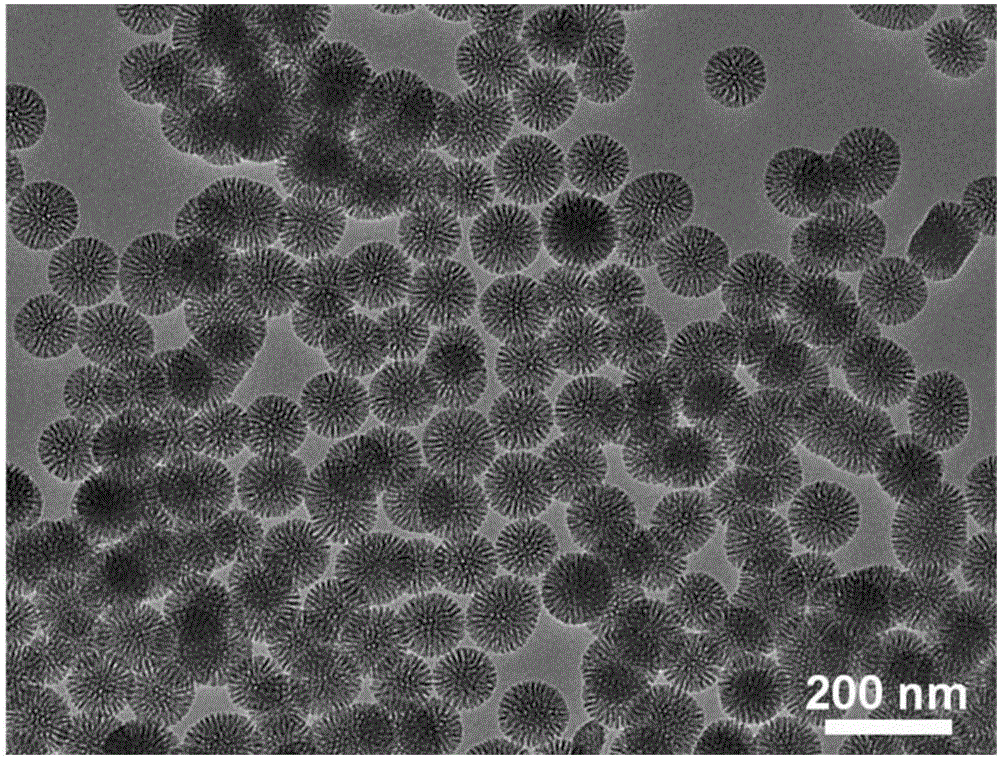

Biodegradable mesoporous carbon and silicon nano-sphere and method for preparing same

A biodegradable, silicon nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as tissue damage, achieve high specific surface area, improve compatibility, good biodegradability degradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Add 6 g of cetyltrimethylammonium chloride (CTAC) and 0.18 g of triethanolamine (TEA) into 55 ml of water, and stir at 60° C. for 1 hour. Add 20 ml of n-hexane solution of tetraethyl orthosilicate (TEOS), the volume ratio of TEOS to n-hexane is 1:6. After 18 hours of reaction, it was centrifuged. The obtained solid product was added to 60 ml of 0.5 wt % ammonium nitrate ethanol solution, and stirred at 60° C. for 5 hours. Centrifuge, wash with ethanol three times, and dry to obtain biodegradable mesoporous silica nanospheres.

[0044] (2) Add 0.2 gram of biodegradable mesoporous silica nanospheres obtained in step (1) and 2 milliliters of γ-aminopropyltriethoxysilane (APTES) to 50 milliliters of toluene and stir at 80°C 10 hours. Centrifugal separation, washing with water and drying to obtain aminated biodegradable mesoporous silica nanospheres.

[0045] (3) Add 0.2 g of the aminated biodegradable mesoporous silica nanospheres obtained in step (2) and 0.06 g of ...

Embodiment 2

[0048] (1) Add 6 g of CTAC and 0.18 g of TEA into 55 ml of water, and stir at 60° C. for 1 hour. Add 20 ml of TEOS in n-hexane solution, the volume ratio of TEOS to n-hexane is 1:8. After 12 hours of reaction, it was centrifuged. The obtained solid product was added to 60 ml of 0.5 wt % ammonium nitrate ethanol solution, and stirred at 60° C. for 5 hours. Centrifuge, wash with ethanol three times, and dry to obtain biodegradable mesoporous silica nanospheres.

[0049] (2) Add 0.2 g of biodegradable mesoporous silica nanospheres obtained in step (1) and 2 ml of APTES into 50 ml of toluene, and stir at 80° C. for 10 hours. Centrifugal separation, washing with water and drying to obtain aminated biodegradable mesoporous silica nanospheres.

[0050] (3) Add 0.2 g of the aminated biodegradable mesoporous silica nanospheres obtained in step (2) and 0.05 g of glucose into 20 ml of water, and conduct a hydrothermal reaction at 150° C. for 24 hours. The solid product was separated ...

Embodiment 3

[0053] (1) Add 6 g of CTAC and 0.18 g of TEA into 55 ml of water, and stir at 60° C. for 1 hour. Add 20 ml of TEOS in n-hexane solution, the volume ratio of TEOS to n-hexane is 1:4. After 24 hours of reaction, it was centrifuged. The obtained solid product was added to 60 ml of 0.5 wt % ammonium nitrate ethanol solution, and stirred at 60° C. for 5 hours. Centrifuge, wash with ethanol three times, and dry to obtain biodegradable mesoporous silica nanospheres.

[0054] (2) Add 0.2 g of biodegradable mesoporous silica nanospheres obtained in step (1) and 2 ml of APTES into 50 ml of toluene, and stir at 80° C. for 10 hours. Centrifugal separation, washing with water and drying to obtain aminated biodegradable mesoporous silica nanospheres.

[0055] (3) Add 0.2 g of the aminated biodegradable mesoporous silica nanospheres obtained in step (2) and 0.08 g of glucose into 20 ml of water, and conduct a hydrothermal reaction at 170° C. for 12 hours. The solid product was separated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com