Sialon ceramic friction welding stirring head and production method thereof

A friction welding and stirring head technology, applied in the field of Sialon ceramic friction welding stirring head and its preparation, can solve the problems of low yield, difficult processing, high manufacturing cost, and achieve long service life, low price, and reduced manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

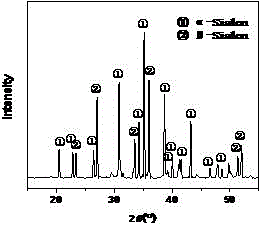

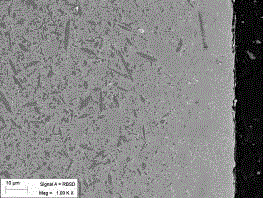

Image

Examples

Embodiment 1

[0040] A process for preparing a sialon ceramic friction welding stirring head, comprising the following steps:

[0041] S1. Prepare sialon ceramic powder: according to the molecular formula Si of sialon ceramics 4 al 2 o 2 N 6 Calculate and weigh the corresponding Si 3 N 4 , AlN and Al 2 o 3 , then add 3wt% Y 2 o 3 , the resulting mixture was ball milled, then dried in an oven at 80°C for 6 hours, and sealed;

[0042] Wherein ball milling also comprises the following steps:

[0043] S11. the corundum of mixed material, different sizes and dehydrated alcohol are packed in the agate ball mill jar according to mass ratio 1:1.5:2;

[0044] S12. Seal the packed ball mill pot and put it into a planetary ball mill for ball milling for 20 hours.

[0045] S2. Gel injection molding:

[0046] S21. Configuration premix: 15wt% N-methylolacrylamide, 9wt% N,N-dimethylethylenediamine and 5vol% ammonium polyacrylate, wherein the ammonium polyacrylate is dissolved in deionized wate...

Embodiment 2

[0054] A process for preparing a sialon ceramic friction welding stirring head, comprising the following steps:

[0055] S1. Prepare sialon ceramic powder: according to the molecular formula Si of sialon ceramics 4 al 2 o 2 N 6 Calculate and weigh the corresponding Si 3 N 4 , AlN and Al 2 o 3 , then add 6wt% Y 2 o 3 , the resulting mixture was ball milled, then dried in an oven at 80°C for 10 hours, and sealed;

[0056] Wherein ball milling also comprises the following steps:

[0057] S11. the corundum of mixed material, different sizes and dehydrated alcohol are packed in the agate ball mill jar according to mass ratio 1:1.5:2;

[0058] S12. Seal the packed ball mill pot and put it into a planetary ball mill for ball milling for 24 hours.

[0059] S2. Gel injection molding:

[0060] S21. Configuration premix: 20wt% N-methylolacrylamide, 10wt% N,N-dimethylethylenediamine and 6vol% ammonium polyacrylate, wherein the ammonium polyacrylate is dissolved in deionized wa...

Embodiment 3

[0068] A process for preparing a sialon ceramic friction welding stirring head, comprising the following steps:

[0069] S1. Prepare sialon ceramic powder: according to the molecular formula Si of sialon ceramics 4 al 2 o 2 N 6 Calculate and weigh the corresponding Si 3 N 4 , AlN and Al 2 o 3 , then add 4wt% Y 2 o 3 , the resulting mixture was ball-milled, then dried in an oven at 80°C for 7 hours, and sealed;

[0070] Wherein ball milling also comprises the following steps:

[0071] S11. the corundum of mixed material, different sizes and dehydrated alcohol are packed in the agate ball mill jar according to mass ratio 1:1.5:2;

[0072] S12. Seal the packed ball mill pot and put it into a planetary ball mill for ball milling for 21 hours.

[0073] S2. Gel injection molding:

[0074] S21. Configuration premix: 16wt% N-methylolacrylamide, 10wt% N,N-dimethylethylenediamine and 6vol% ammonium polyacrylate, wherein the ammonium polyacrylate is dissolved in deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com