Preparation method of urea formaldehyde and polyolefin coating material of fertilizers

A coating material, polyolefin technology, applied in fertilizer mixtures, layered/coated fertilizers, fertilization devices, etc., can solve the problems of human food pollution, resource waste, economic loss, fertilizer loss, etc., and achieve a simple and easy preparation method. Industrialized production, the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

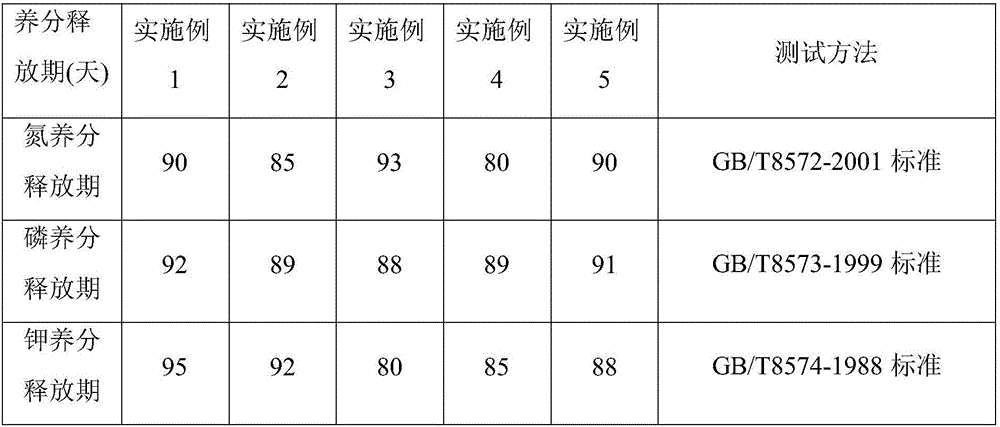

Examples

Embodiment 1

[0009] A preparation method of urea-formaldehyde and polyolefin as a fertilizer coating material, comprising the following raw materials in parts by weight: 80 parts of urea-formaldehyde, 20 parts of polyolefin, and 5 parts of crosslinking agent. Put parts by weight of urea-formaldehyde and polyolefin in a reaction kettle, add water to stir and mix evenly, heat to 80°C, gelatinize, then add parts by weight of cross-linking agent, reflux at 100°C to make cross-linking Afterwards, stirring, cooling and discharging to obtain a dispersion of urea-formaldehyde and polyolefin coating material in water. The prepared urea-formaldehyde / polyolefin coating material aqueous dispersion is coated on the surface of fertilizer particles by spraying to prepare a coated slow-release fertilizer.

Embodiment 2

[0011] A preparation method of urea-formaldehyde and polyolefin as a fertilizer coating material, comprising the following raw materials in parts by weight: 70 parts of urea-formaldehyde, 10 parts of polyolefin, and 3 parts of crosslinking agent. Put parts by weight of urea-formaldehyde and polyolefin in a reaction kettle, add water to stir and mix evenly, heat to 70°C, gelatinize, then add parts by weight of cross-linking agent, reflux at 90°C to make cross-linking Afterwards, stirring, cooling and discharging to obtain a dispersion of urea-formaldehyde and polyolefin coating material in water. The prepared urea-formaldehyde / polyolefin coating material aqueous dispersion is coated on the surface of fertilizer particles by spraying to prepare a coated slow-release fertilizer.

Embodiment 3

[0013] A preparation method of urea-formaldehyde and polyolefin as a fertilizer coating material, comprising the following raw materials in parts by weight: 75 parts of urea-formaldehyde, 15 parts of polyolefin, and 3 parts of crosslinking agent. Put parts by weight of urea-formaldehyde and polyolefin in a reaction kettle, add water, stir and mix evenly, heat to 70°C, gelatinize, then add parts by weight of cross-linking agent, and reflux at 100°C to make cross-linking Afterwards, stirring, cooling and discharging to obtain a dispersion of urea-formaldehyde and polyolefin coating material in water. The prepared urea-formaldehyde / polyolefin coating material aqueous dispersion is coated on the surface of fertilizer particles by spraying to prepare a coated slow-release fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com