Calcium alginate-chitosan microspheres and preparation method thereof, drug-loaded calcium alginate-chitosan and preparation method thereof

A technology of chitosan microspheres and calcium alginate, which is applied in antibacterial drugs, microcapsules, drug delivery, etc., can solve the problems affecting the overall uniformity of drug carriers, wide particle size distribution of microspheres, and difficulty in precise control. Achieve the effect of easy and precise control, uniform particle size and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

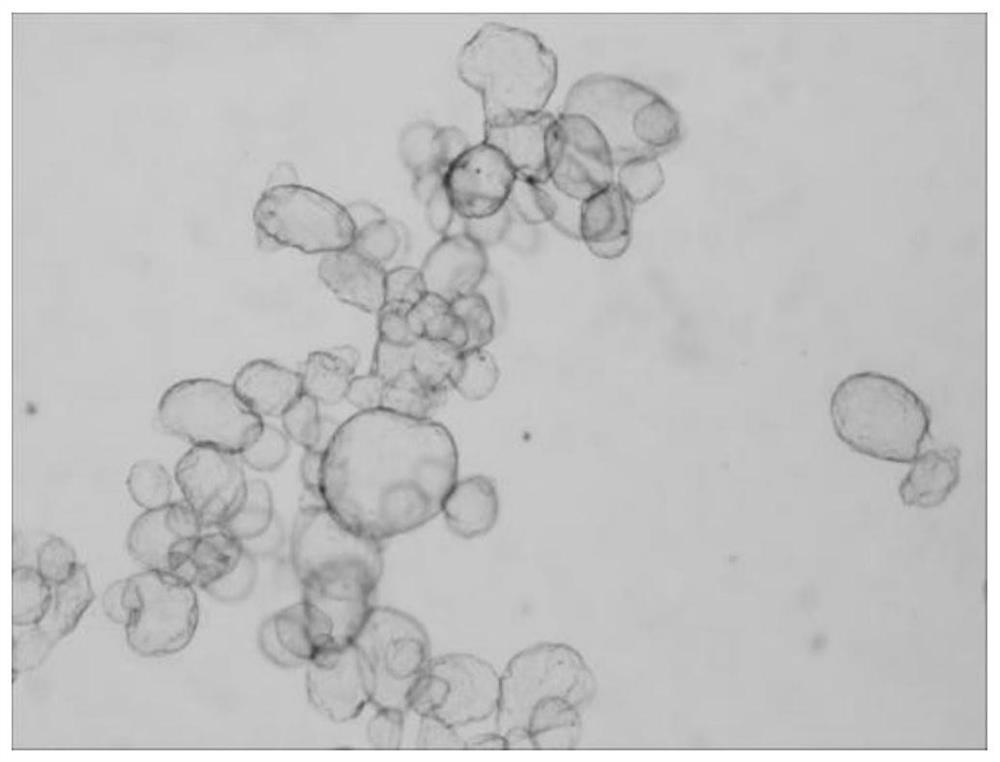

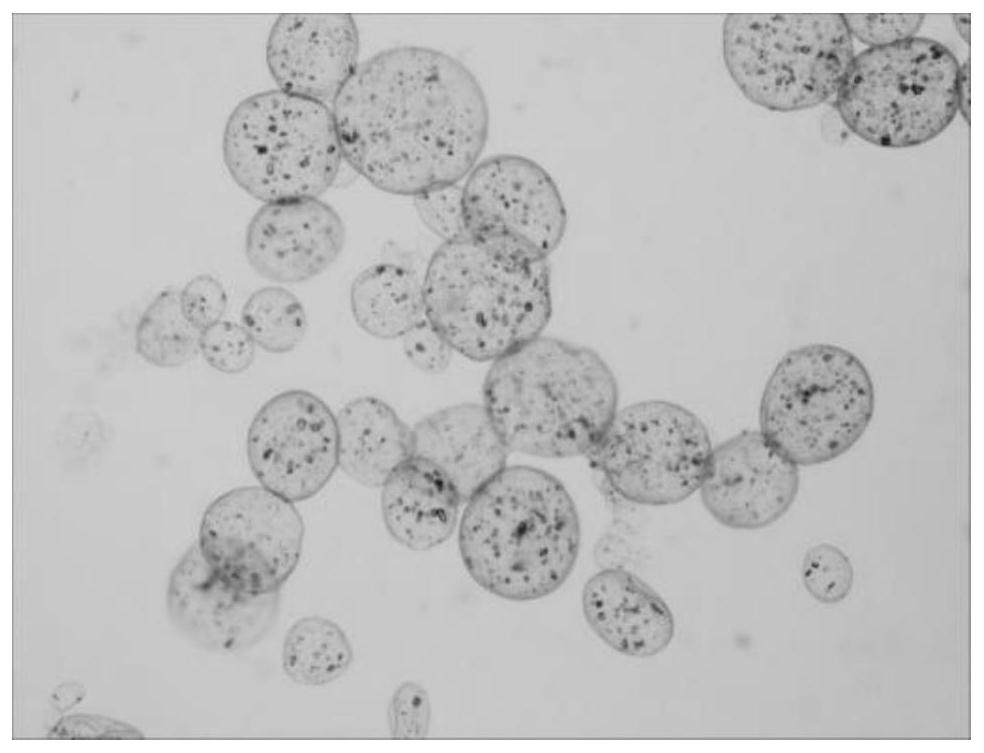

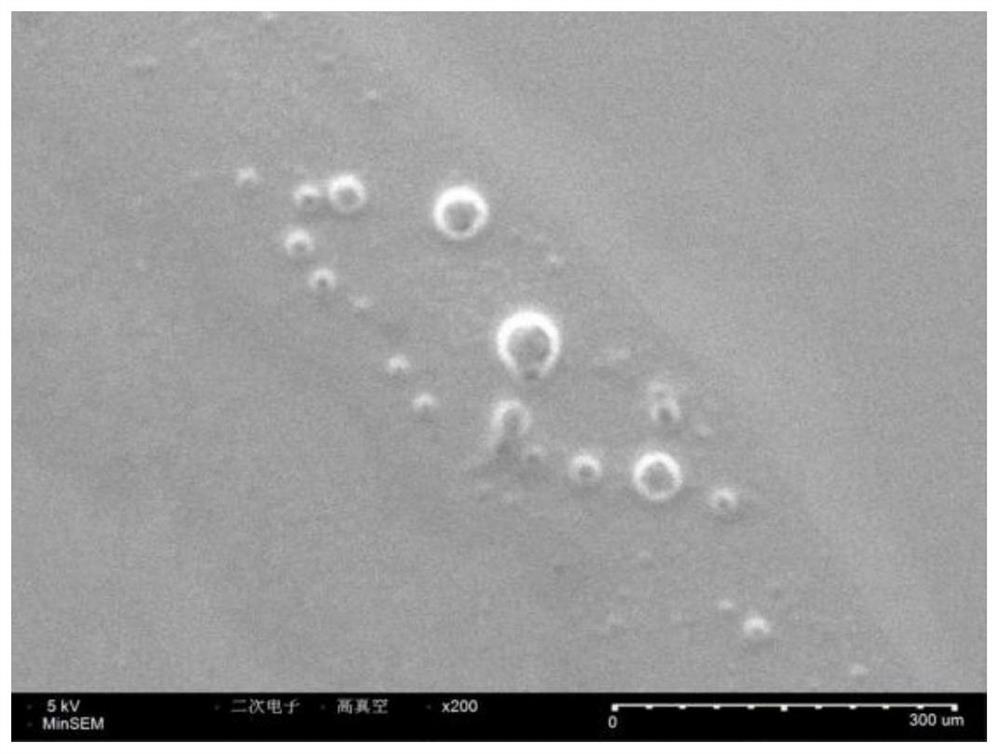

[0033] According to one aspect of the present invention, the present invention provides a method for preparing calcium alginate-chitosan microspheres, comprising the steps of: electrostatically spraying sodium alginate solution into a mixed solution of chitosan and calcium chloride , to obtain calcium alginate-chitosan microspheres.

[0034] In the preparation method of calcium alginate-chitosan microspheres provided by the present invention, the sodium alginate solution is sprayed into the mixed solution of chitosan and calcium chloride by electrostatic spraying, and the microspheres can be prepared, the process is simple, and the operation is convenient , and the particle size of the microspheres is uniform, and the particle size distribution is 20-50 μm, which makes it easier to control the slow and controlled release of the drug after it is loaded with the drug.

[0035] In a preferred embodiment of the present invention, the mass concentration of the sodium alginate solut...

Embodiment 1

[0084] The present embodiment provides a kind of calcium alginate-chitosan microsphere, and its preparation method comprises the steps:

[0085] (1) Prepare sodium alginate solution with water as solvent, the mass concentration of sodium alginate is 1.5%;

[0086] (2) Prepare a mixed solution of chitosan and calcium chloride with acetic acid as a solvent, wherein the concentration of chitosan is 0.2%, and the concentration of calcium chloride is 1%;

[0087] (3) The sodium alginate solution was sprayed into the mixed solution of chitosan and calcium chloride by electrostatic spraying at a spray speed of 4.5 mL / h;

[0088] (4) Centrifuge the solution in step (3) at a speed of 5000 rpm, remove the supernatant, and then wash with deionized water 3 times to obtain calcium alginate-chitosan microsphere suspension, freeze-dry , to obtain calcium alginate-chitosan microspheres.

Embodiment 2

[0090] This embodiment provides a kind of calcium alginate-chitosan microspheres, the difference of its preparation method and embodiment 1 is, in step (1), the mass concentration of sodium alginate solution is 4%; In (2), in the mixed solution of chitosan and calcium chloride, the mass concentration of chitosan is 0.05%, and the mass concentration of calcium chloride is 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com