A kind of preparation method of star polycarboxylate water reducer

A technology of polycarboxylate and water reducer, which is applied in the field of preparation of star-shaped polycarboxylate water reducer, can solve the problems of easy formation of cross-linked polymers, high price, uncontrollable reaction, etc., achieve simple process and solve the problem of preparation difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

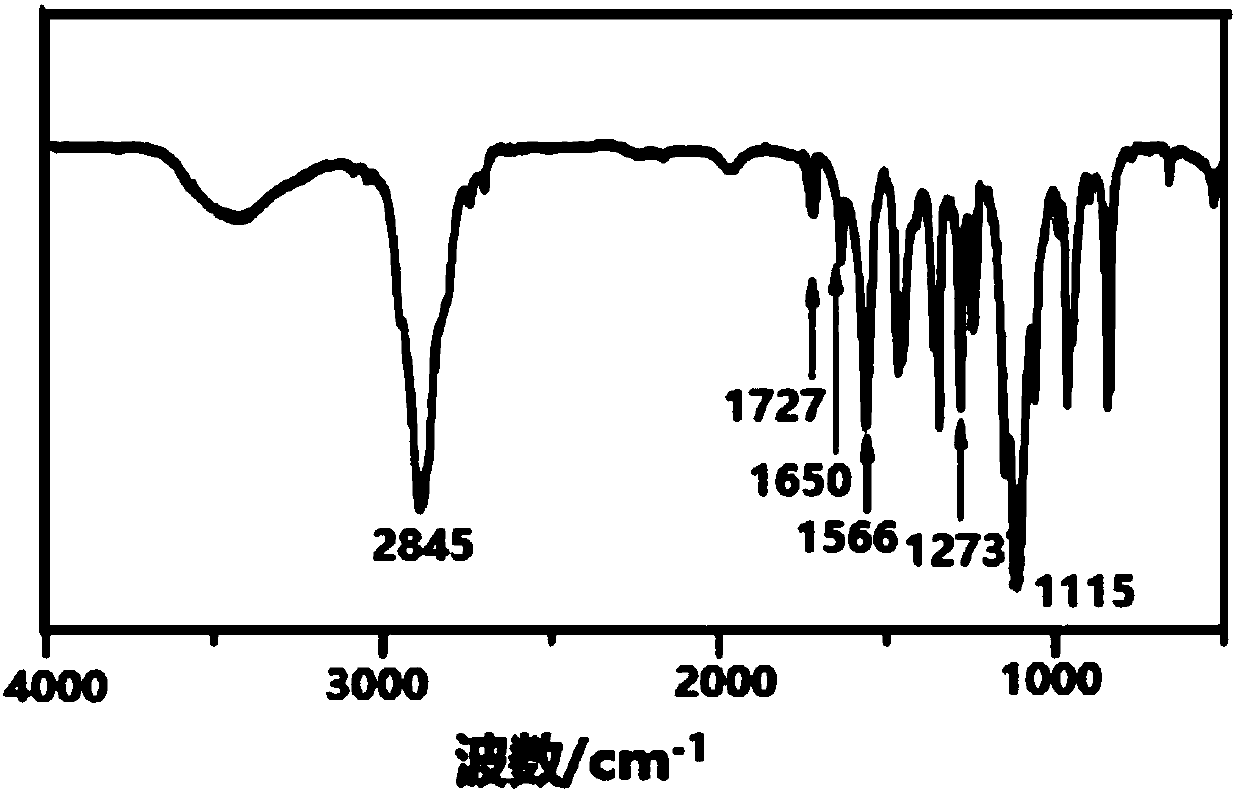

Image

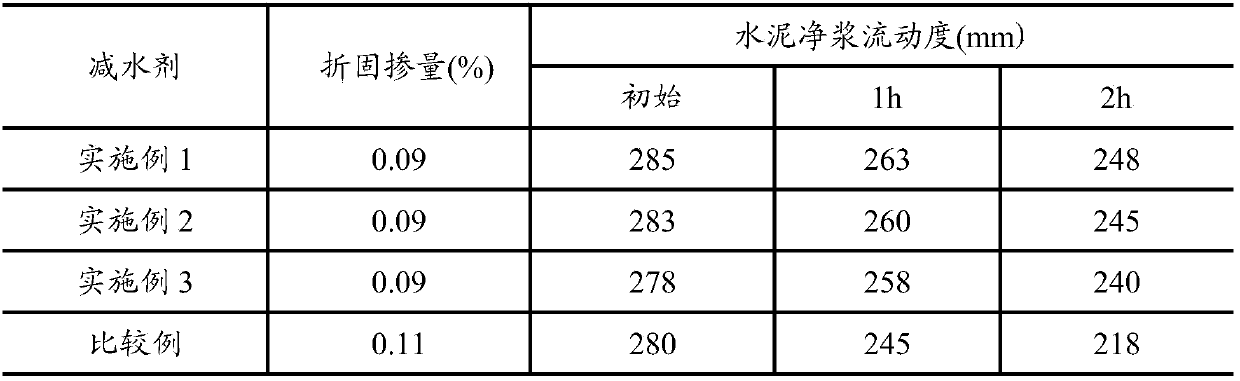

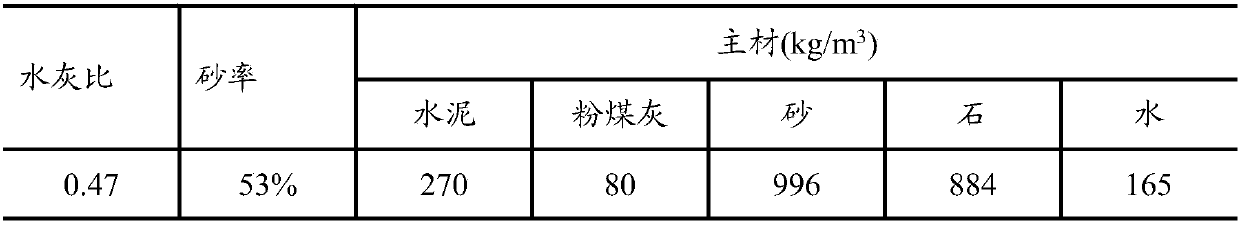

Examples

preparation example Construction

[0022] The invention provides a preparation method of a star-shaped polycarboxylate water reducer, comprising the following steps:

[0023] Mixing the double bond-containing monomer, nucleating agent and water to obtain a monomer-nucleating agent mixed solution, wherein the nucleating agent includes pentaerythritol tris(3-mercaptopropionate), triethanolamine tris(3-mercaptopropionate) acid) ester, a kind of in glucose tetrakis (3-mercaptopropionic acid) ester and ethylenediamine tetrakis (2-mercaptoethyl acetate);

[0024] Provide an aqueous solution of initiator;

[0025] Provide terminal double bond polyoxyethylene ether aqueous solution;

[0026] The monomer-nucleating agent mixed solution and the initiator aqueous solution are simultaneously added dropwise to the terminal double bond polyoxyethylene ether aqueous solution to carry out a polymerization reaction to obtain a star-shaped polycarboxylate water reducer.

[0027] In the present invention, a monomer containing a...

Embodiment 1

[0047] In a dropping tank with stirring and metering, 135 kg of acrylic acid, 7.5 kg of pentaerythritol tris(3-mercaptopropionate) and 332.5 kg of water were added to obtain a monomer-nucleating agent mixed solution, which was stirred and dissolved for subsequent use.

[0048] In another dropping tank with stirring and measuring meter, 7.5 kg of ammonium persulfate and 242.5 kg of water were added to obtain an aqueous initiator solution, which was heated to 50° C. for subsequent use after stirring and dissolving.

[0049] Add 1500kg of prenol polyoxyethylene ether (n=20) and 3500kg of water to the reaction kettle, turn on stirring, and heat to 50°C. After the temperature of the bottom of the kettle is accurately controlled, the monomer-nucleating agent mixed solution and the initiator aqueous solution are added dropwise at the same time, and the drop rate is controlled to be 3kg / min. water agent, and then cooled to room temperature for 1.5h at a rate of 0.33°C / min to obtain a ...

Embodiment 2

[0052] In the dropping tank with stirring and metering, add 225kg of maleic anhydride, 30kg of glucose tetrakis (3-mercaptopropionate) and 280kg of water to obtain a monomer-nucleating agent mixed solution, which is heated to 75 g after stirring and dissolving. ℃ reserve.

[0053] In another dropping tank with a stirring and measuring meter, 30 kg of sodium persulfate and 120 kg of water were added to obtain an aqueous initiator solution, which was heated to 75° C. for subsequent use after stirring and dissolving.

[0054] Add 1500kg of methallyl alcohol polyoxyethylene ether (n=75) and 2282kg of water to the reaction kettle, turn on stirring, and heat to 75°C. After the temperature of the bottom of the kettle is accurately controlled, the monomer-nucleating agent mixed solution and the initiator aqueous solution are added dropwise at the same time, and the drop rate is controlled to be 3kg / min. water agent, then cool down at a rate of 0.5°C / min, and cool to room temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com