A kind of nano-gas-conducting film for improving the appearance of fiber composite materials and its preparation method

A fiber composite material and air-conducting film technology, applied in the field of composite material molding, can solve the problems of harsh working environment, lack of glue in products, increase material cost and labor intensity, etc., and achieve the effect of smooth and full appearance and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A nano gas-conducting film for improving the appearance of fiber composite materials, and a preparation method, the specific steps are as follows:

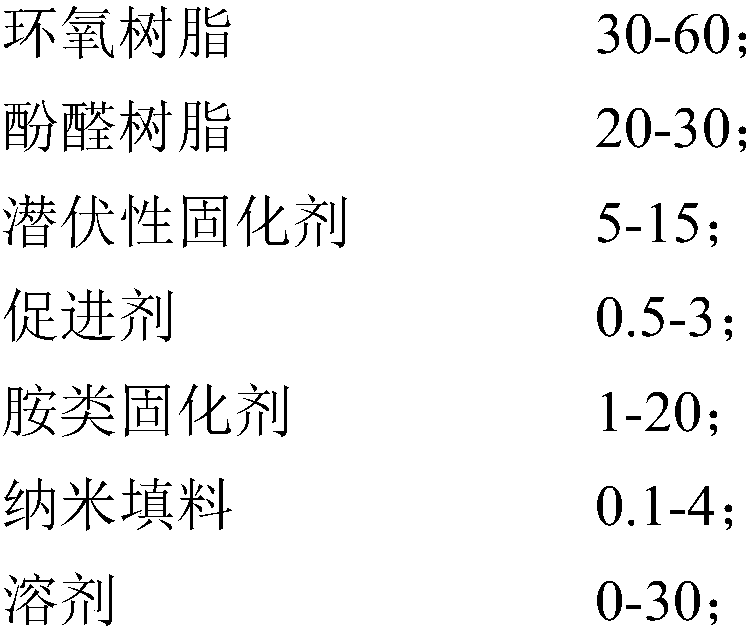

[0051] (1) Take the following components by parts by weight, stir and mix evenly to obtain the mixture;

[0052]

[0053] (2) coating the mixture obtained in step (1) on the release substrate, and drying it;

[0054] (3) Cover one layer of release substrate on the surface of the dried mixture to form a structure with the mixture as the middle layer and the release substrate as the upper and lower surface layers;

[0055] (4) Winding or cutting into sheets of appropriate size to obtain a nano gas-conducting film for improving the appearance of the fiber composite material.

[0056] Its structure is as figure 1 As shown, 1 is the release substrate, which is located on the upper and lower sides, and plays a protective role for the middle layer; 2 is the middle layer formed by coating the mixture, which is the part where t...

Embodiment 2

[0061] A nano gas-conducting film for improving the appearance of fiber composite materials, a preparation method, and the specific steps are as follows:

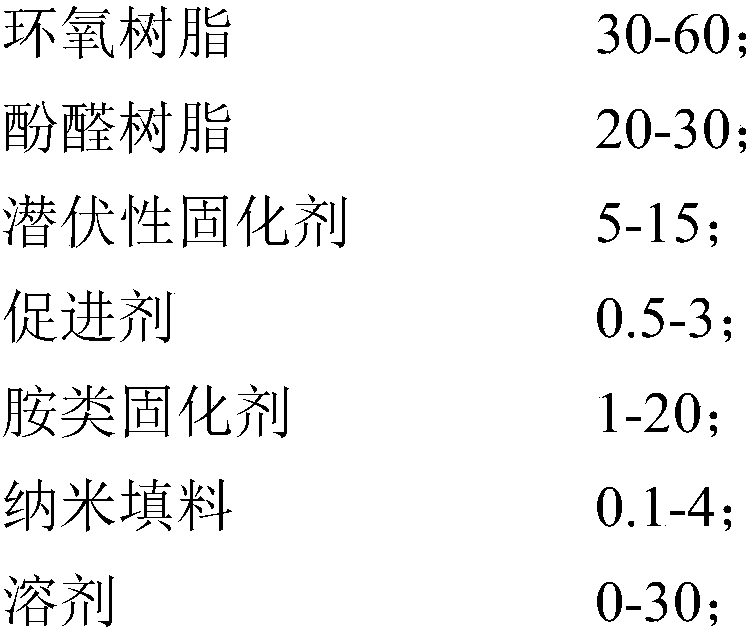

[0062] (1) Take the following components by parts by weight, stir and mix evenly to obtain the mixture;

[0063]

[0064]

[0065] (2) coating the mixture obtained in step (1) on the release substrate, and drying it;

[0066] (3) Cover one layer of release substrate on the surface of the dried mixture to form a structure with the mixture as the middle layer and the release substrate as the upper and lower surface layers;

[0067] (4) Winding or cutting into sheets of appropriate size to obtain a nano gas-conducting film for improving the appearance of the fiber composite material.

[0068] Among them, the epoxy resin is epoxy resin E-12, the latent curing agent is dicyandiamide; the accelerator is organic urea UR300; the amine curing agent is alicyclic amine EC210; the silicon dioxide is amorphous silicon dioxide. T...

Embodiment 3

[0072] A nano gas-conducting film for improving the appearance of fiber composite materials, a preparation method, and the specific steps are as follows:

[0073] (1) Take the following components by parts by weight, stir and mix evenly to obtain the mixture;

[0074]

[0075]

[0076] (2) coating the mixture obtained in step (1) on the release substrate;

[0077] (3) A layer of release substrate is covered on the surface of the mixture to form a structure with the mixture as the middle layer and the release substrate as the upper and lower surface layers;

[0078] (4) Winding or cutting into sheets of appropriate size to obtain a nano gas-conducting film for improving the appearance of the fiber composite material.

[0079] Among them, the epoxy resin is epoxy resin E-44, the latent curing agent is dicyandiamide; the accelerator is organic urea UR500; the amine curing agent is alicyclic amine EC210; the carbon nanotube is a single-arm structure with a diameter of 1- 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com