Processing method for obtaining rice particles with smooth and full surfaces

A technology with smooth surface and processing method, applied in grain smoothing, polishing composition containing abrasives, grain degermination, etc. The effect of rice rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

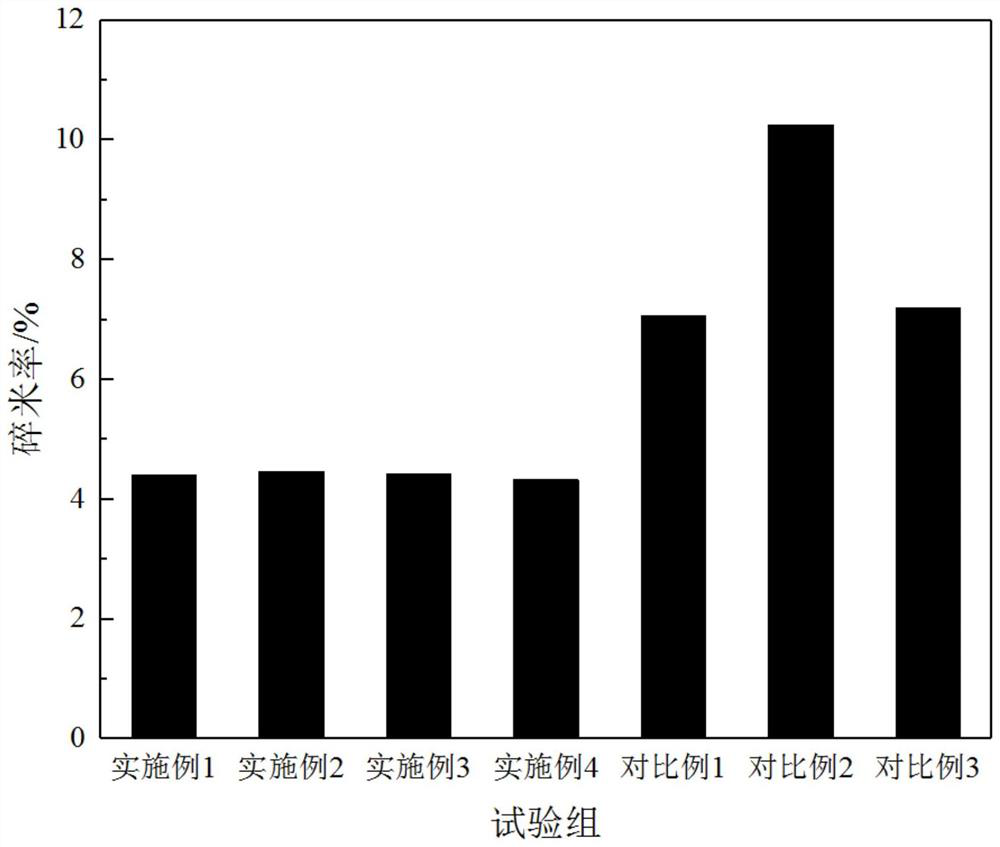

Examples

Embodiment 1

[0015] A processing method for obtaining smooth and plump rice grains, the steps comprising:

[0016] 1) Configure a mixed aqueous solution of sodium dodecylsulfonate, trishydroxymethylaminomethane, and HCl. In the mixed aqueous solution of sodium dodecylsulfonate, trishydroxymethylaminomethane, and HCl, dodecyl The mass percent composition of sodium sulfonate is 1%, the concentration of trishydroxymethylaminomethane is 0.05mol / L, the concentration of HCl is 0.05mol / L, and the solvent is water; Porcini mushrooms are chopped, and the broken dices are dissolved in the liquid Grind into powder in nitrogen, then add the powder into the mixed aqueous solution of sodium dodecylsulfonate, trishydroxymethylaminomethane, and HCl, add the sodium dodecylsulfonate, three The solid-to-liquid ratio solid / liquid in the mixed aqueous solution of hydroxymethylaminomethane and HCl = 1 g: 20 mL. Constant temperature in water bath to 90±5°C, keep warm for 30min, air cool to room temperature afte...

Embodiment 2

[0020] A processing method for obtaining smooth and plump rice grains, the steps comprising:

[0021] 1) Configure a mixed aqueous solution of sodium dodecylsulfonate, trishydroxymethylaminomethane, and HCl. In the mixed aqueous solution of sodium dodecylsulfonate, trishydroxymethylaminomethane, and HCl, dodecyl The mass percent composition of sodium sulfonate is 1%, the concentration of trishydroxymethylaminomethane is 0.05mol / L, the concentration of HCl is 0.05mol / L, and the solvent is water; Porcini mushrooms are chopped, and the broken dices are dissolved in the liquid Grind into powder in nitrogen, then add the powder into the mixed aqueous solution of sodium dodecylsulfonate, trishydroxymethylaminomethane, and HCl, add the sodium dodecylsulfonate, three The solid-to-liquid ratio solid / liquid in the mixed aqueous solution of hydroxymethylaminomethane and HCl = 1 g: 20 mL. Constant temperature in water bath to 90±5°C, keep warm for 30min, air cool to room temperature afte...

Embodiment 3

[0025] A processing method for obtaining smooth and plump rice grains, the steps comprising:

[0026] 1) Configure a mixed aqueous solution of sodium dodecylsulfonate, trishydroxymethylaminomethane, and HCl. In the mixed aqueous solution of sodium dodecylsulfonate, trishydroxymethylaminomethane, and HCl, dodecyl The mass percentage composition of sodium sulfonate is 2%, the concentration of trishydroxymethylaminomethane is 0.05mol / L, the concentration of HCl is 0.05mol / L, and solvent is water; Pork belly mushroom is chopped, and broken diced is in liquid Grind into powder in nitrogen, then add the powder into the mixed aqueous solution of sodium dodecylsulfonate, trishydroxymethylaminomethane, and HCl, add the sodium dodecylsulfonate, three The solid-to-liquid ratio solid / liquid in the mixed aqueous solution of hydroxymethylaminomethane and HCl = 1 g: 30 mL. Constant temperature in water bath to 90±5°C, keep warm for 30min, air cool to room temperature after warm keeping, sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com