Environment-friendly rust-proof polishing solution for mechanical equipment

A kind of mechanical equipment and environment-friendly technology, which is applied in the direction of polishing composition, polishing composition containing abrasives, chemical instruments and methods, etc., can solve problems such as easy to produce odor, rust on the surface of mechanical equipment, environmental pollution, etc., to avoid Burn, simple preparation method, effect of lowering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

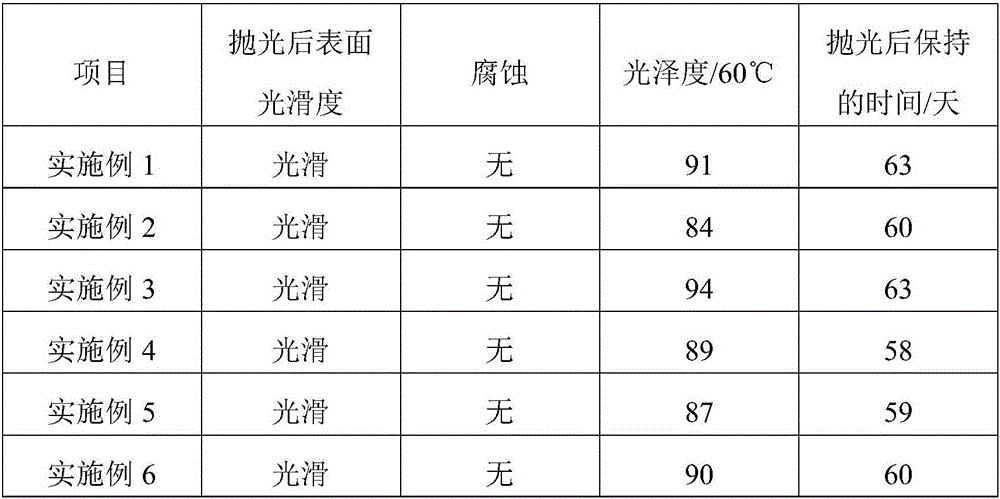

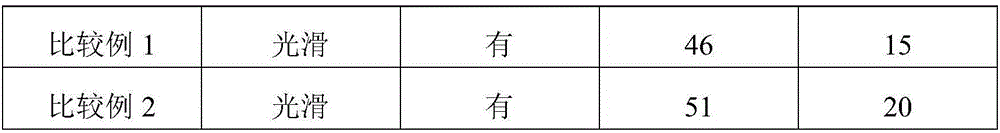

Examples

Embodiment 1

[0024] Embodiment 1: a kind of environment-friendly antirust polishing solution for mechanical equipment, the raw material of described environment-friendly antirust polishing solution is made up of following parts by weight: 40 parts of silicon micropowder, 10 parts of antirust agent, 15 parts of salicylic acid, 10 parts of cellulose acetate, 40 parts of paraffin, 6 parts of methanol, 7 parts of organic solvent, 5 parts of surfactant, 5 parts of stabilizer and 50 parts of water.

[0025] The paraffin is No. 50 crude paraffin; the fineness of the silicon micropowder is 400-500 mesh.

[0026] The rust inhibitor contains sodium phosphate.

[0027] The organic solvent is ethanol, propanol or butanol.

[0028] The surfactant is at least one of linear alkylbenzene sulfonate sodium, fatty alcohol polyoxyethylene ether sodium sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, lignin sulfonate and stearic acid monoglyceride.

[0029] The stabilizer is at least one of lau...

Embodiment 2

[0031] Embodiment 2: a kind of environment-friendly antirust polishing solution for mechanical equipment, all the other are the same as embodiment 1, the difference is that the raw materials of the environment-friendly antirust polishing solution are composed of the following parts by weight: 34 parts of silicon micropowder, 14 parts of rust inhibitor, 11 parts of salicylic acid, 5 parts of cellulose acetate, 20 parts of paraffin, 9 parts of methanol, 9 parts of organic solvent, 3 parts of surfactant, 4 parts of stabilizer and 46 parts of water.

[0032] The fineness of the silicon micropowder is 1500-1600 mesh.

Embodiment 3

[0033] Embodiment 3: a kind of environment-friendly antirust polishing solution for mechanical equipment, all the other are the same as embodiment 1, the difference is that the raw materials of the environment-friendly antirust polishing solution are composed of the following parts by weight: 30 parts of silicon micropowder, 17 parts of rust inhibitor, 20 parts of salicylic acid, 15 parts of cellulose acetate, 28 parts of paraffin, 15 parts of methanol, 6 parts of organic solvent, 6 parts of surfactant, 2 parts of stabilizer and 55 parts of water.

[0034] The fineness of the silicon micropowder is 900-1000 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com