High-D-lactic acid-yield recombinant bacterium and application thereof

A technology of recombinant bacteria and lactic acid, applied in the field of bioengineering, can solve the problems of poor optical purity of products, low yield and conversion rate, difficult synthesis of lactic acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

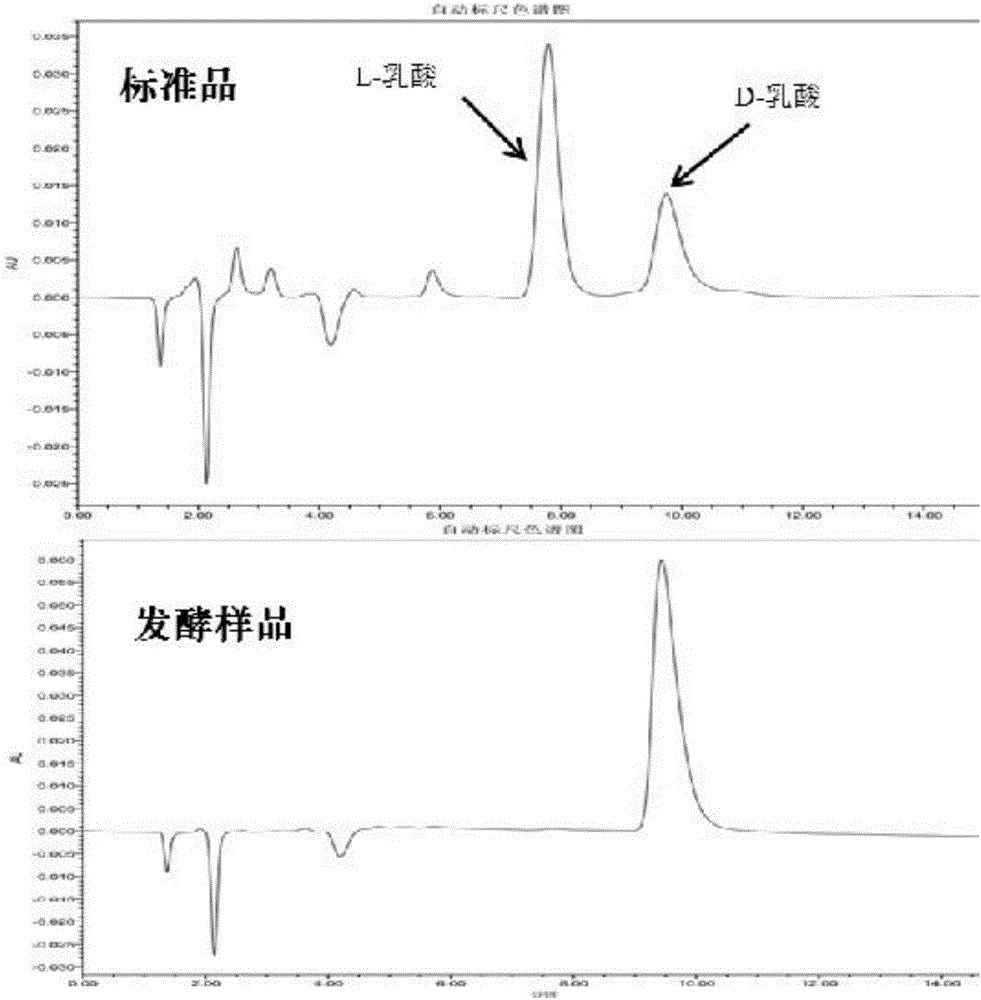

Image

Examples

Embodiment 1

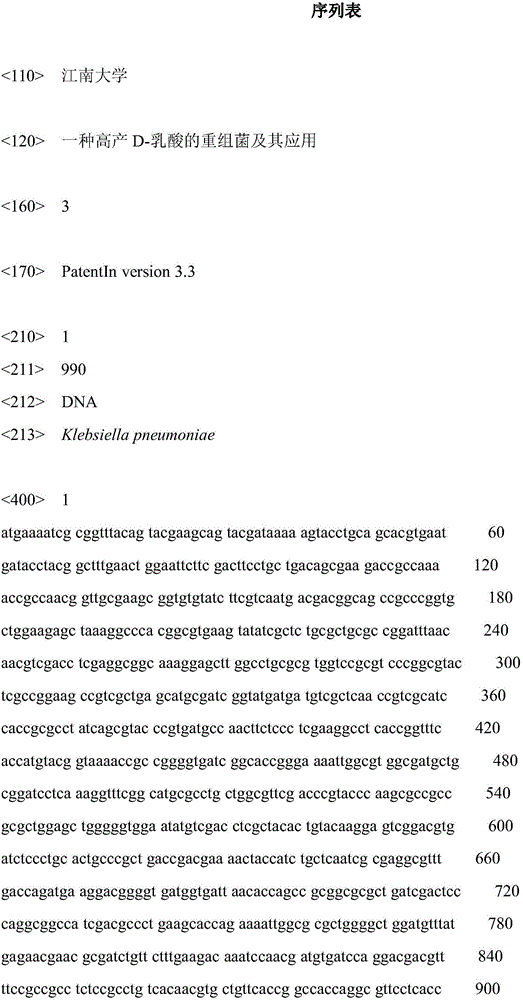

[0048] Example 1 Cloning of exogenous genes

[0049] Obtain the D-lactate dehydrogenase gene (ldhA) derived from K.pneumoniae (Genbank accession number is CP000964.1, or as shown in SEQ ID NO.1), which is obtained by PCR amplification using K.pneumoniae as a template The ldhA gene. Primers were designed as follows:

[0050] 5'-CGAGCTCTATAATCACTGGAGAAAAGT-3'

[0051] 5'-GCTCTAGAGAATCAGACGATGGCGTTCG-3', and then use the recovery kit to recover the target fragment.

Embodiment 2

[0052] Example 2 Construction of expression vector

[0053] The D-lactate dehydrogenase ldhA gene fragment obtained in Example 1 and the plasmid pBAD18 were digested with SacI and XbaI, and the digested products were recovered, and then ligated. The molar ratio of the vector and the ldhA gene fragment was 1:5, at 16°C The recombinant plasmid pBAD18-ldhA was constructed after ligation for more than 6 hours, and transformed into E.coli DH5α, and then spread on a medium containing 100 μg·mL -1 On LB solid medium with kanamycin, positive clones were screened by PCR. After the recombinant plasmid pBAD18-ldhA was extracted from the positive clone, it was identified by restriction enzyme digestion and sequencing.

Embodiment 3

[0054] Example 3 Obtaining of D-lactic acid-producing recombinant bacteria

[0055] Inoculate wild-type Klebsiella pneumoniae K. peneumoniae into 20 mL of LB liquid medium, add 50 μg·mL -1 Kanamycin, cultured to a certain concentration of bacteria. Use a sterilized centrifuge tube to centrifuge at 5500 rpm at 4°C for 5 minutes, remove the supernatant, suspend with sterile water stored at 4°C, and centrifuge again, repeating twice. Then resuspend with sterile water, aliquot and store at -80°C to obtain competent cells.

[0056] The expression vector obtained in Example 2 was transformed by electric shock and transferred into K. peneumoniae competent cells to obtain recombinant Klebsiella pneumoniae.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com