Wear-resistant packing paper with high structure strength, and production method thereof

A technology of structural strength and wrapping paper, applied in the direction of wrapping paper, wrapping paper, packaging, etc., can solve the problems of poor wear resistance, easy aging, and short service life, so as to improve wear resistance, not easy to age, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

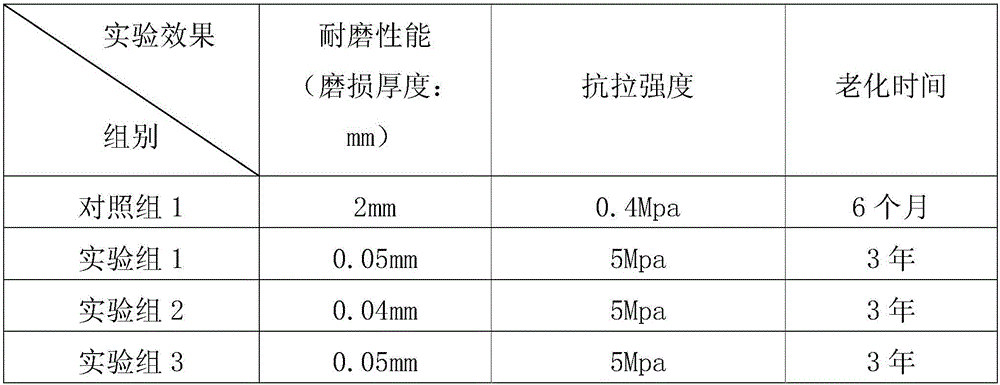

Examples

Embodiment 1

[0023] A wear-resistant wrapping paper with high structural strength, made of the following materials in proportion by weight: 80 parts of kraft wood pulp, 7 parts of cellulose, 14 parts of xylan, 5 parts of chrome alum, and 2 parts of nano-silver , 7 parts of carbon fiber, 15 parts of cotton fiber, 9 parts of polyacrylonitrile, 8 parts of polyethylene glycol, 6 parts of ash, 11 parts of phenolic resin, 7 parts of polypropylene, 6 parts of magnesium hydroxide, 2 parts of red phosphorus, coconut oil 1 part, 4 parts of paraffin, 2 parts of diatomaceous earth, 6 parts of aluminum tripolyphosphate, 13 parts of morpholine, 14 parts of p-phenylenediamine, 22 parts of ethylene-vinyl acetate copolymer, 9 parts of silicone oil and 3 parts of latex.

[0024] A method for preparing a wear-resistant wrapping paper with high structural strength, comprising the following steps:

[0025] 1) Mix 80 parts of kraft wood pulp, 7 parts of cellulose, 14 parts of xylan, 5 parts of chrome alum, 2 pa...

Embodiment 2

[0033] A wear-resistant wrapping paper with high structural strength, made of the following materials in proportion by weight: 82.5 parts of kraft wood pulp, 9 parts of cellulose, 15 parts of xylan, 7.5 parts of chrome alum, and 4 parts of nano-silver , 9 parts of carbon fiber, 20 parts of cotton fiber, 11.5 parts of polyacrylonitrile, 9 parts of polyethylene glycol, 7 parts of ash, 12.5 parts of phenolic resin, 9.5 parts of polypropylene, 7 parts of magnesium hydroxide, 3 parts of red phosphorus, coconut oil 1.5 parts, 5.5 parts of paraffin, 2.5 parts of diatomaceous earth, 7 parts of aluminum tripolyphosphate, 14.5 parts of morpholine, 16 parts of p-phenylenediamine, 23 parts of ethylene-vinyl acetate copolymer, 12 parts of silicone oil and 5.5 parts of latex.

[0034] A method for preparing a wear-resistant wrapping paper with high structural strength, comprising the following steps:

[0035]1) 82.5 parts of kraft wood pulp, 9 parts of cellulose, 15 parts of xylan, 7.5 part...

Embodiment 3

[0043] A wear-resistant wrapping paper with high structural strength, made of the following materials in proportion by weight: 85 parts of kraft wood pulp, 11 parts of cellulose, 16 parts of xylan, 10 parts of chrome alum, and 6 parts of nano-silver , 11 parts of carbon fiber, 25 parts of cotton fiber, 14 parts of polyacrylonitrile, 10 parts of polyethylene glycol, 8 parts of ash, 14 parts of phenolic resin, 12 parts of polypropylene, 8 parts of magnesium hydroxide, 4 parts of red phosphorus, coconut oil 2 parts, 7 parts of paraffin, 3 parts of diatomaceous earth, 8 parts of aluminum tripolyphosphate, 16 parts of morpholine, 18 parts of p-phenylenediamine, 24 parts of ethylene-vinyl acetate copolymer, 15 parts of silicone oil and 8 parts of latex.

[0044] A method for preparing a wear-resistant wrapping paper with high structural strength, comprising the following steps:

[0045] 1) Mix 85 parts of kraft wood pulp, 11 parts of cellulose, 16 parts of xylan, 10 parts of chrome ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com