Transformation method for achieving diversion of rain and sewage in non-partitioned plain-type refuse landfill

A landfill, rain and sewage diversion technology, applied in the direction of sewage discharge, waterway system, water supply equipment, etc., can solve the problems of increasing leachate production, discharging into the environment, and insufficient treatment capacity, etc., to achieve reduction Operating costs, stress relief, and the effects of overcoming defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

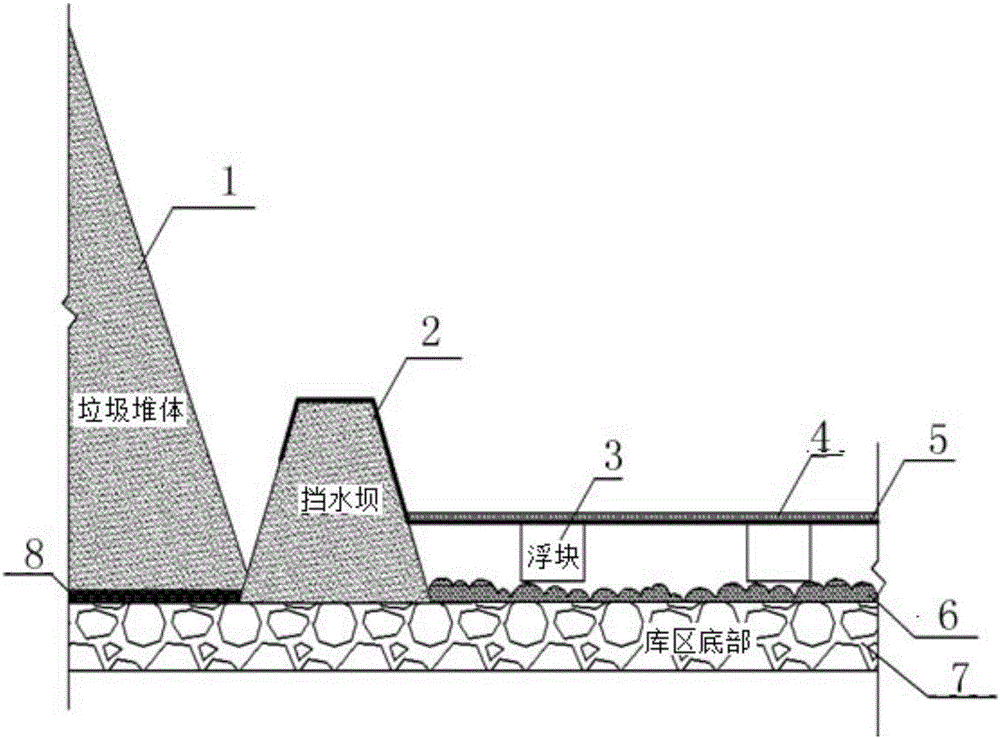

[0012] The invention provides a transformation method for realizing rain and sewage diversion in undivided plain type garbage landfills. The present invention will be described below in conjunction with the accompanying drawings.

[0013] figure 1 Shown is a large sample of HDPE film laying in the landfill in the waste rain and sewage diversion area. figure 1 as shown,

[0014] The retaining dam 2 around the garbage dump body 1 on the bottom 7 of the reservoir area, the retaining dam 2 and the unfilled area are respectively covered with HDPE film 5; the rainwater 4 flows through the HDPE film 5 to the bottom 7 of the reservoir area to form rainwater leachate 6. A plurality of floating blocks are placed on the rainwater leachate 6 to support the HDPE membrane 5; there is a sewage leachate 8 on the bottom 7 of the reservoir area, and the rainwater leachate 6 and the sewage leachate 8 are separated by the retaining dam 2; To achieve the purpose of rain and sewage diversion in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com