Shield cutter head with refrigeration function and shield tunneling machine

A shield cutter head and function technology, which is applied in soil protection, infrastructure engineering, mining equipment and other directions, can solve the problems of easy water penetration, difficult construction and high technical difficulty on the face of the tunnel and the top of the excavation space. The effect of reducing interaction time, easy to ensure strength, and strengthening weak points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

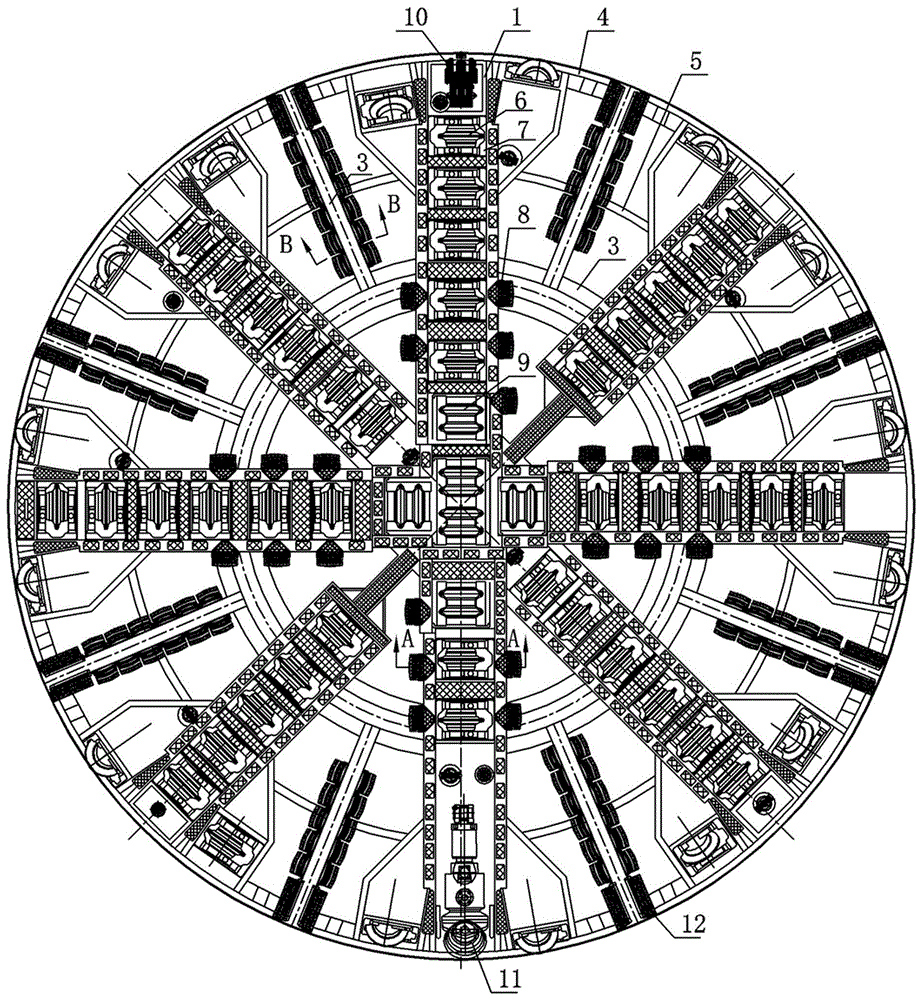

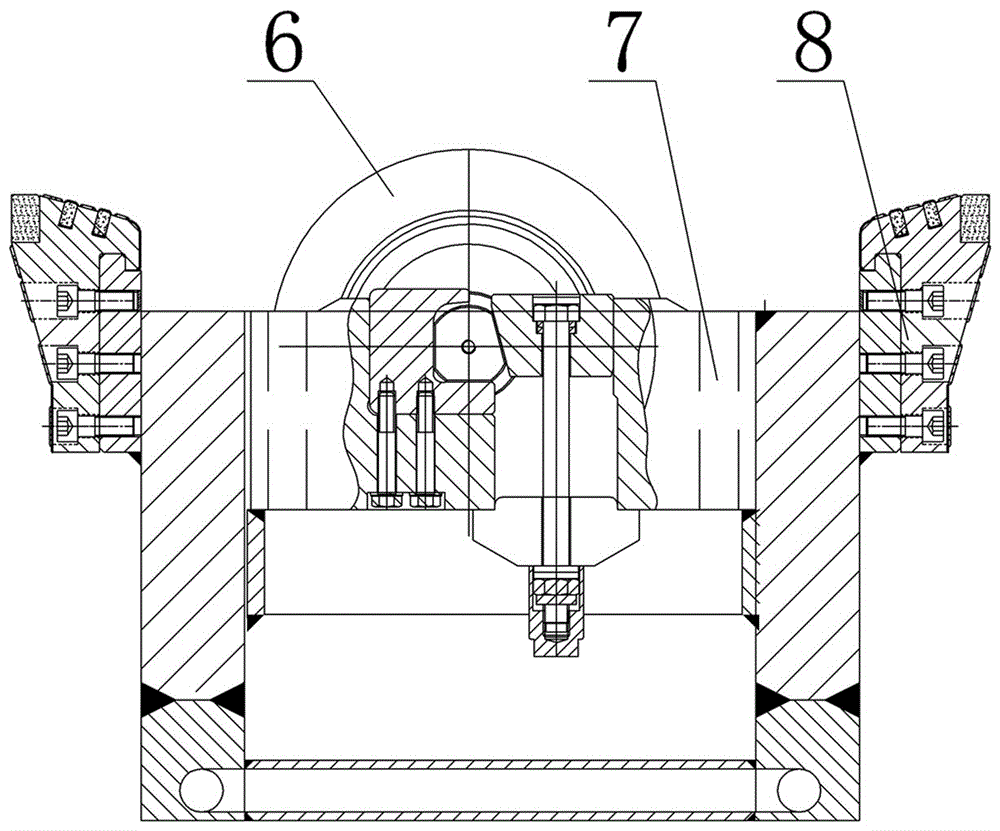

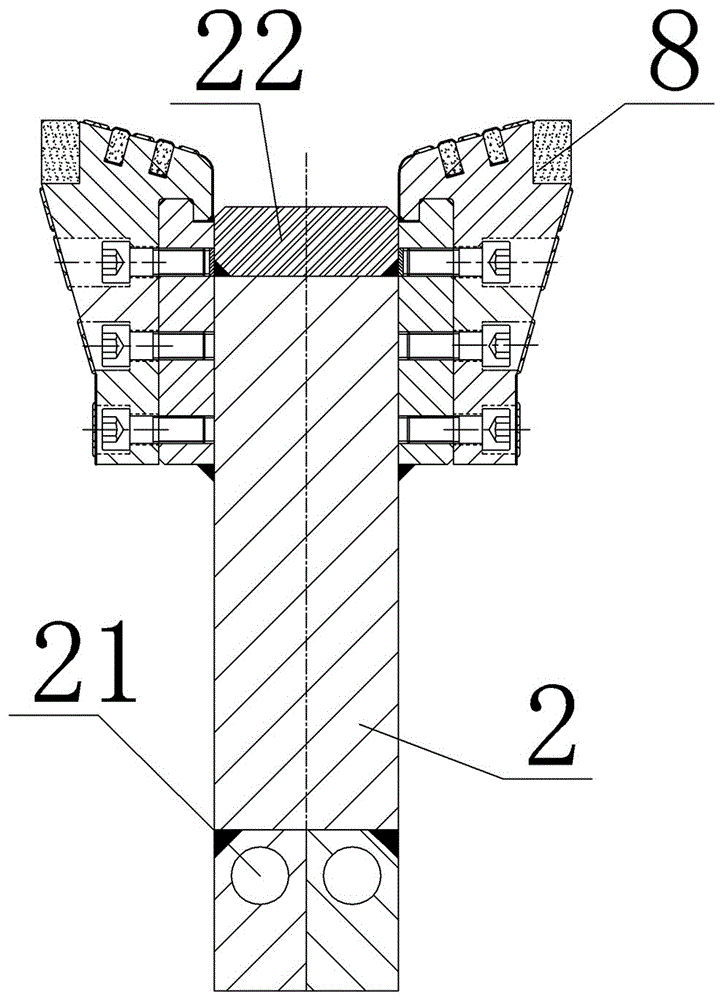

[0021] Embodiment 1: see Figure 1 to Figure 4 , a shield cutterhead with freezing function, comprising a disk-shaped cutterhead body composed of a plurality of spoke beams and a freezing pipeline arranged on the cutterhead body, the spoke beams are composed of a main body equipped with several hobs The spoke beam and the sub-spoke beam equipped with several scrapers are composed of several main and sub-spoke beams which are radially distributed and arranged alternately around the center of the cutterhead body. On the main spoke beam, its outer end is connected with the outer end of the adjacent main spoke beam through a ring beam, and a scraper protection block is arranged on the front working surface of the auxiliary spoke beam. Between the circular ring beam and the main ring beam, there is a circular reinforcing rib for connecting the adjacent main and auxiliary spoke beams; the backs of the several main and auxiliary spoke beams are provided with cooling fluid arranged al...

Embodiment 2

[0025] Embodiment 2: not shown in the figure, a shield machine comprising the above-mentioned shield cutter head with freezing function, also includes main drive, front shield, middle shield, propulsion cylinder, hinged cylinder, shield tail, segment installation machine , rear supporting system and freezing station, the freezing station is placed in the supporting system behind the shield machine, the freezing station is composed of a refrigerator, a brine tank, a brine pump, a clean water pump and a cooling tower, and the inlet of the clean water pump is connected to a water source , its outlet communicates with the cooling tower through a pipeline, and a brine pump is provided in the brine tank, and the brine pump pumps the brine in the brine tank into the freezer for cooling, and the outlet of the freezer is connected to the freezing tube through a pipeline road connection. In this embodiment, the main drive, front shield, middle shield, propulsion cylinder, articulated cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com