A diesel engine high pressure common rail system

A high-pressure common rail system and high-pressure common rail technology, applied in the charging system, mechanical equipment, engine control, etc., can solve the problems of easy pressure fluctuation, difficult to withstand oil pressure, processing accuracy limitations, etc., and achieve the highest damping limit fuel Pressure, good accumulation and distribution of fuel, damping effect of fuel pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

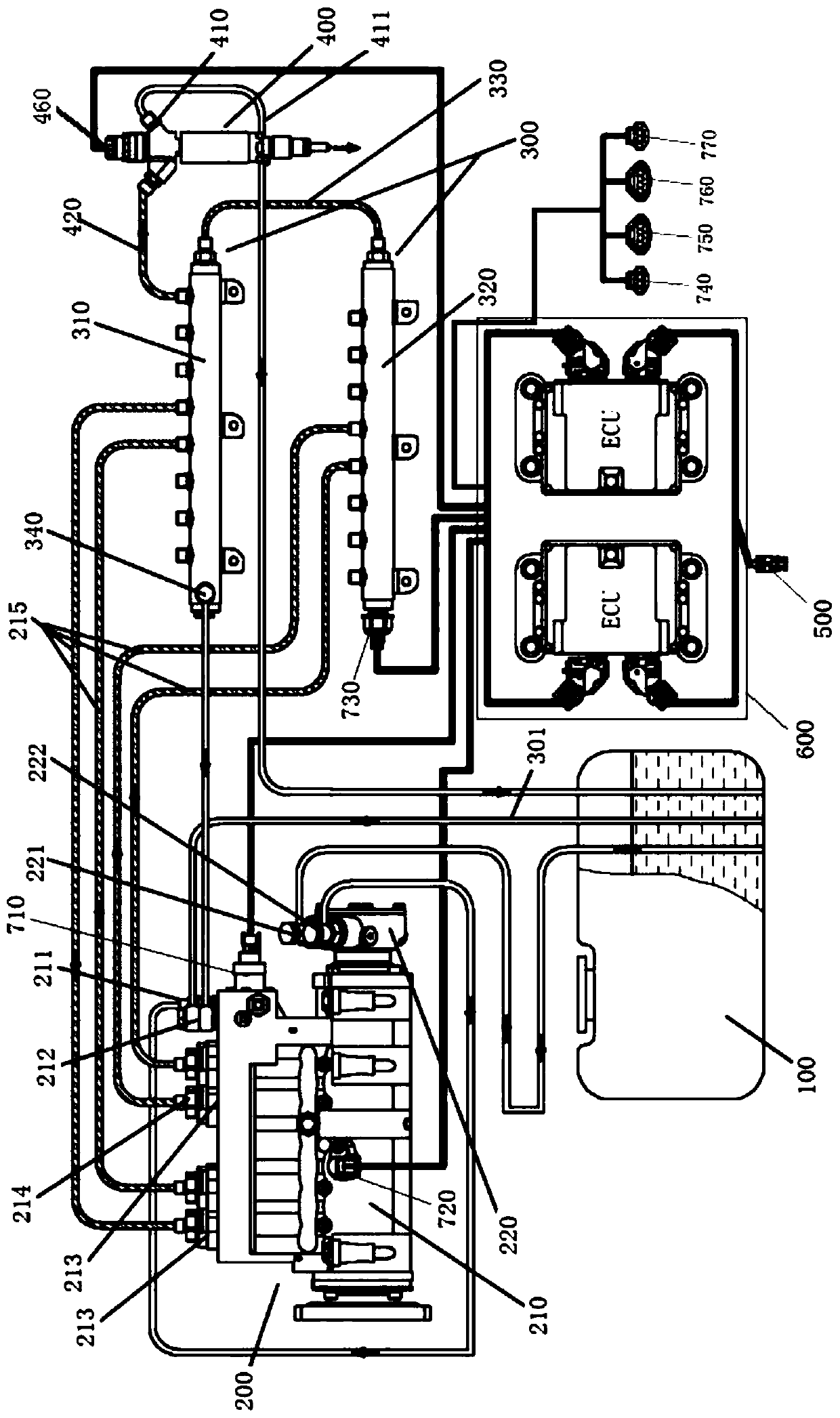

[0038] Such as figure 1 As shown, the present invention provides a diesel engine high-pressure common rail system, including: a mechanical system and an electronic control system;

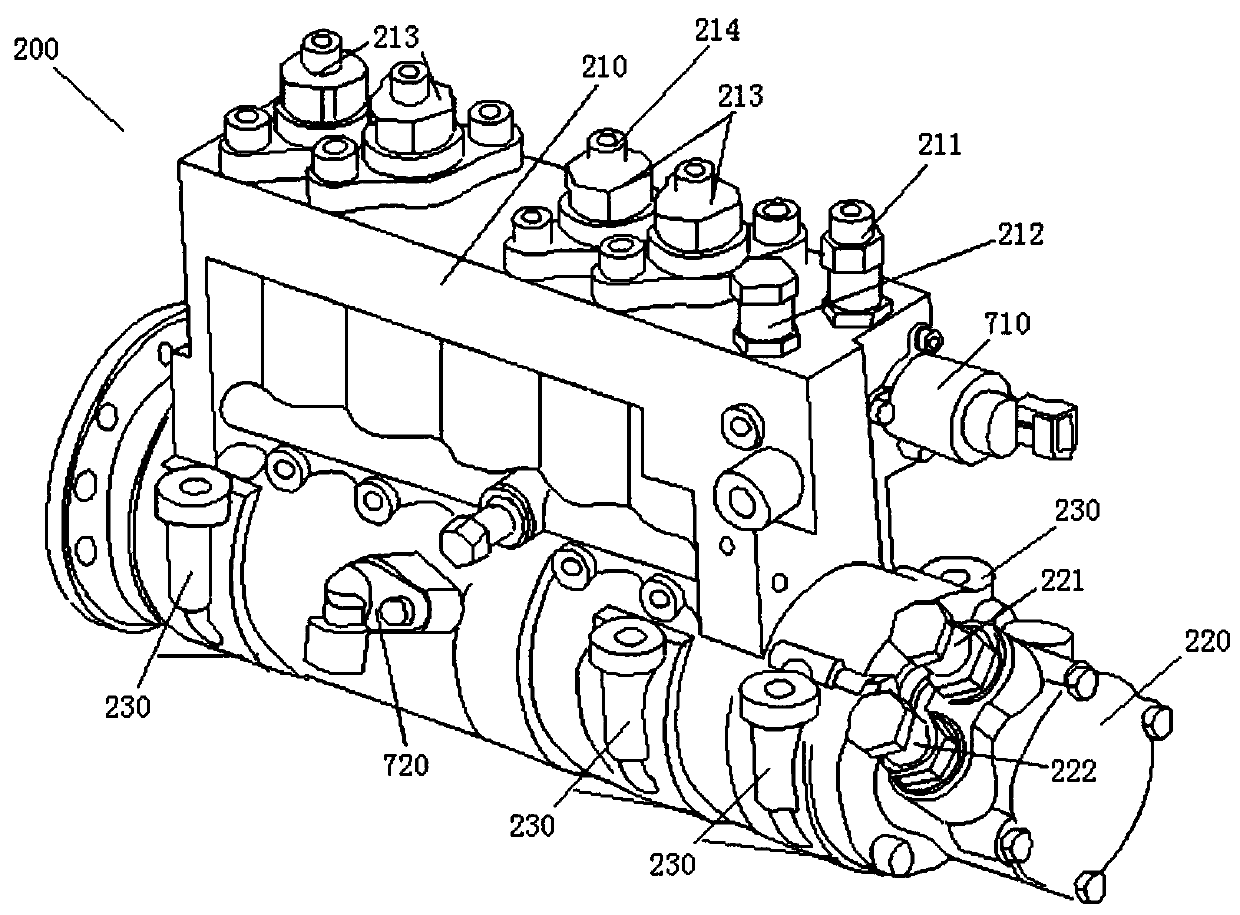

[0039] The mechanical system includes: a high-pressure common rail fuel injection pump 200, a high-pressure common rail pipe 300 and a fuel injector 400; wherein, the structure of the high-pressure common rail fuel injection pump 200 is as follows figure 2 As shown; the high-pressure common rail fuel injection pump 200 includes: a high-pressure pump 210 and a fuel delivery pump 220; the fuel delivery pump 220 is arranged at one end of the high-pressure pump 210, and the other end of the high-pressure pump 210 is connected to the gear of the diesel engine The diesel engine camshaft transmission connection in the tank; the connection ports of the fuel delivery pump 220 include: the fuel oil low-pressure fuel inlet valve 221 of the fuel delivery pump and the fuel low-pressure fuel outlet valve 222 of...

Embodiment 2

[0050] Figure 4 As shown, in this embodiment, on the basis of Embodiment 1, the high-pressure common rail system of the diesel engine further includes: an oil-water separator 800 and a diesel filter 900; The diesel filter 900 and the fuel low-pressure fuel inlet valve 211 of the high-pressure pump are sequentially connected in series through oil pipes. The invention further provides an oil-water separator and a diesel oil filter for the high-pressure common-rail system of the diesel engine to provide cleaner fuel supply for the high-pressure common-rail system of the diesel engine by way of filtering, and provides strong structural support for the stable operation of the diesel engine.

[0051] preferred, such as Figure 4 As shown, in a preferred technical solution of this embodiment, the electronic control unit is also provided with an OBD fault diagnosis interface 780 . The present invention further provides a powerful structural support for the electronic control system...

Embodiment 3

[0053] Figure 5 As shown, in this embodiment, on the basis of the above embodiments, the camshaft rotation position detection device includes: a fuel injection pump camshaft phase sensor 721 and a camshaft phase gear 722; the camshaft phase gear 722 is fixed on the high pressure pump cam shaft, the setting position of the camshaft phase sensor of the fuel injection pump matches the setting position of the camshaft phase gear; a plurality of camshaft phase teeth are uniformly arranged on the camshaft phase gear; when multiple When the camshaft phase teeth of the fuel injection pump respectively pass through the detection area of the camshaft phase sensor of the fuel injection pump, the camshaft phase sensor of the fuel injection pump feeds back a detection signal.

[0054] In the present invention, the high-pressure pump is equipped with a camshaft rotation position detection device, and the technical effect of detecting the diesel engine speed is also achieved by detecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com