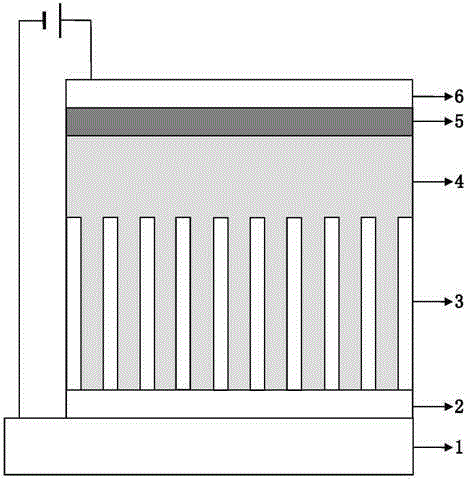

Organic-inorganic hybrid electroluminescent device and preparation method thereof

An electroluminescent device and inorganic composite technology, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of poor stability of organic materials affecting the working life of devices, wide emission spectrum, and hindering the industrialization process of devices, etc. problems, to achieve the effects of easy large-scale production, low preparation cost, and improved electron and hole injection balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

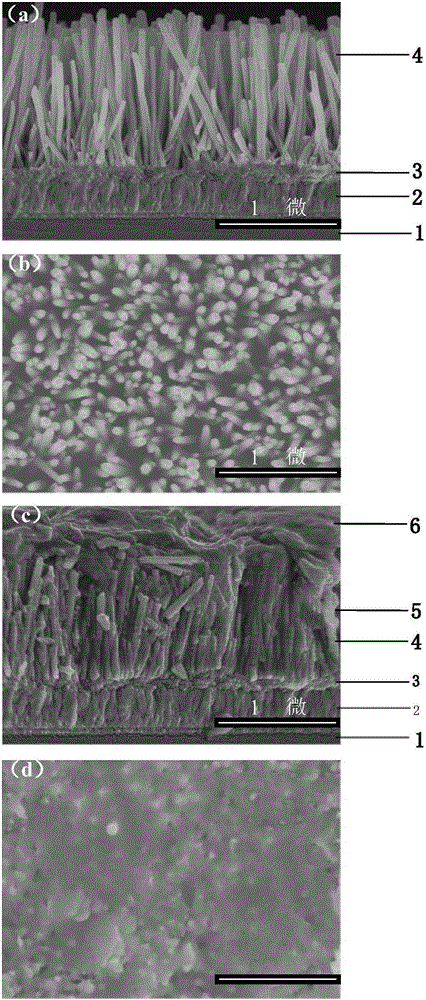

Embodiment 1

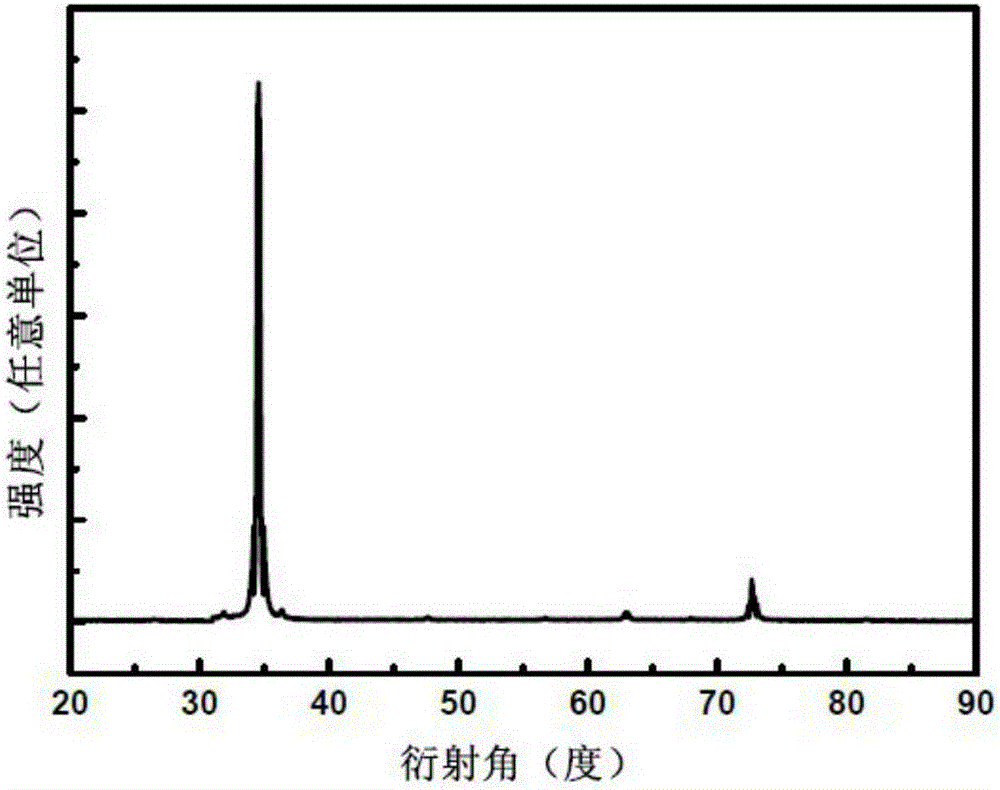

[0047] (1) Preparation of ZnO seed layer

[0048] Alternately ultrasonically clean the ITO glass substrate with deionized water, acetone, isopropanol, and ethanol, repeat 4 times, dry in vacuum at 80°C for 30 minutes, and irradiate with ultraviolet light for 30 minutes; spin-coat the zinc oxide quantum dot solution on The ITO glass substrate was vacuum-dried at 80°C, taken out after 20 minutes, and lowered to room temperature to complete a cycle; repeat this 3 times. The resulting ZnO seed layer had a thickness of 40 nm.

[0049] (2) Setup of ZnO nanoarrays

[0050] Weigh 0.59 g of zinc nitrate hexahydrate and 0.28 g of hexamethylenetetramine, dissolve them in 40 ml of deionized water respectively, mix the two solutions, stir and mix with magnetic force at room temperature for 20 min, and transfer the mixed solution into the autoclave. Put the substrate loaded with the ZnO seed layer into an autoclave with a filling degree of 80%, and keep the temperature at 90°C for 8 hours...

Embodiment 2

[0058] The steps are basically the same as in Example 1, and only the differences are described as follows:

[0059] 1) Use PET coated with ITO conductive film as the substrate;

[0060] 2) Spin coating with 5g of ZnO quantum dots, 3g of PVK, and 1g of PMMA mixed solution to make an organic-inorganic composite luminescent layer;

[0061] 3) Al is used as the metal anode.

Embodiment 3

[0062] Example 3, the steps are basically the same as in Example 1, except that 1g of ZnO quantum dot powder, 1g of PVK, and 0.5g of PMMA are dissolved in 100g of DMF solution to prepare an organic-inorganic composite light-emitting layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com