Gel electrolyte porous electrode for lithium-sulfur battery and preparation and application of gel electrolyte porous electrode

A gel electrolyte and porous electrode technology, applied in non-aqueous electrolyte battery electrodes, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of inability to stack and dry, high degree of binder crystallization, and energy consumption. Achieve good ion transmission ability, improve rate performance, and improve the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Dissolve 1g of PVDF-HFP in 17g of N-methylpyrrolidone (NMP), stir for 1h, add 2g of S / A-KB600, stir for 5h, adjust the scraper to 300μm, scrape and form a film on the aluminum film, and quickly immerse in water , Take it out after 10 minutes, and dry overnight at 50°C. Subsequent electrode preparation and battery assembly are the same as the comparative example.

[0038]The specific capacity of the first cycle discharge is 1308mA h g -1 , the capacity maintained at 907mA h g after 100 cycles -1 , the capacity retention rate is 69.3%; when the rate is increased to 1C, the discharge specific capacity is 817mA h g -1 .

Embodiment 2

[0040] Weigh 0.7g polyacrylonitrile (PAN, Mw=150000), and 0.3g polyethylene glycol (PEG, Mw=6000), stir and dissolve in 17g DMF solution, add 2g S / A-KB600, stir for 5h , to obtain a mixture. Subsequent electrode preparation, drying, and battery assembly test steps are the same as in Example 1.

[0041] The specific capacity of the first cycle discharge is 1338mA h g -1 , the capacity maintained at 1034mA h g after 100 cycles -1 , the capacity retention rate is 77.3%; when the rate is increased to 1C, the discharge specific capacity is 748mA h g -1 .

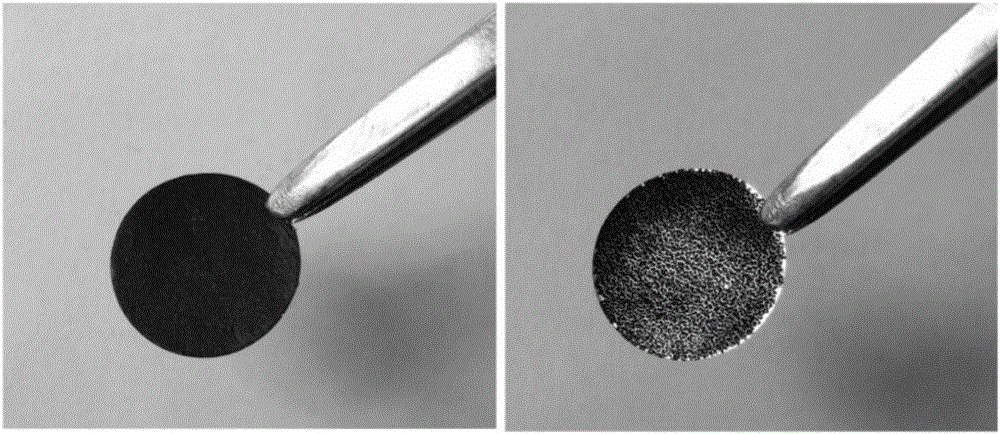

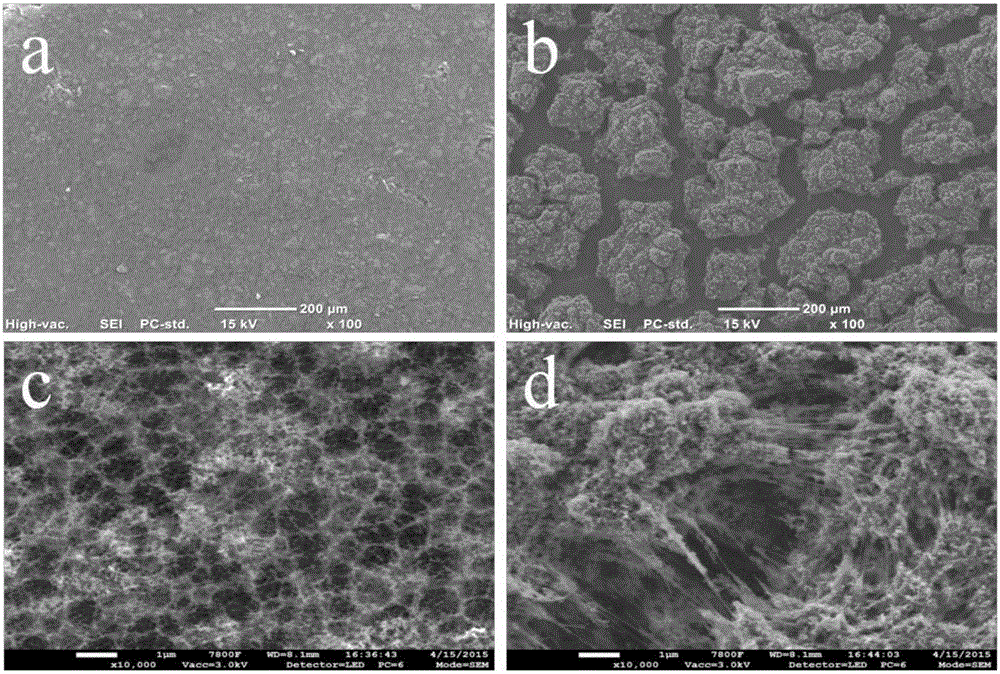

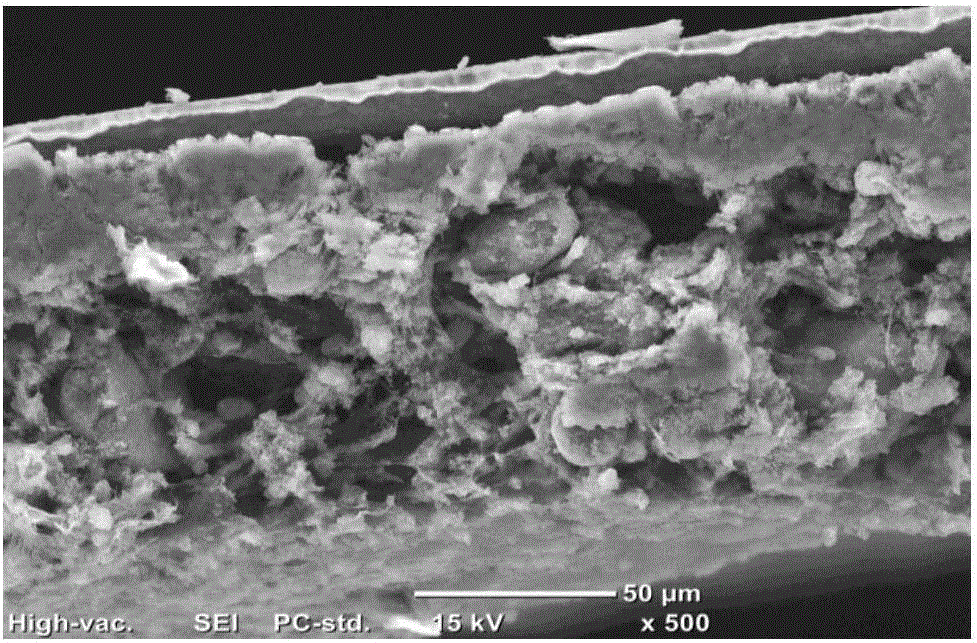

[0042] Depend on figure 1 It can be seen that the electrode of Example 1 is relatively smooth as a whole, and no obvious defects are seen, while the comparative example is severely cracked, and the carbon material on the edge has fallen off, indicating that the gel electrolyte porous electrode prepared by the immersion phase inversion method is better than the electrode prepared by the traditional method. The bond between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com