Method for isomerization of 2,5-dichlorotoluene with catalysis of metal Ag modified molecular sieve

A dichlorotoluene and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as dependence on imports, restrict downstream product development and research, and achieve low cost of raw materials, easy reaction control, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

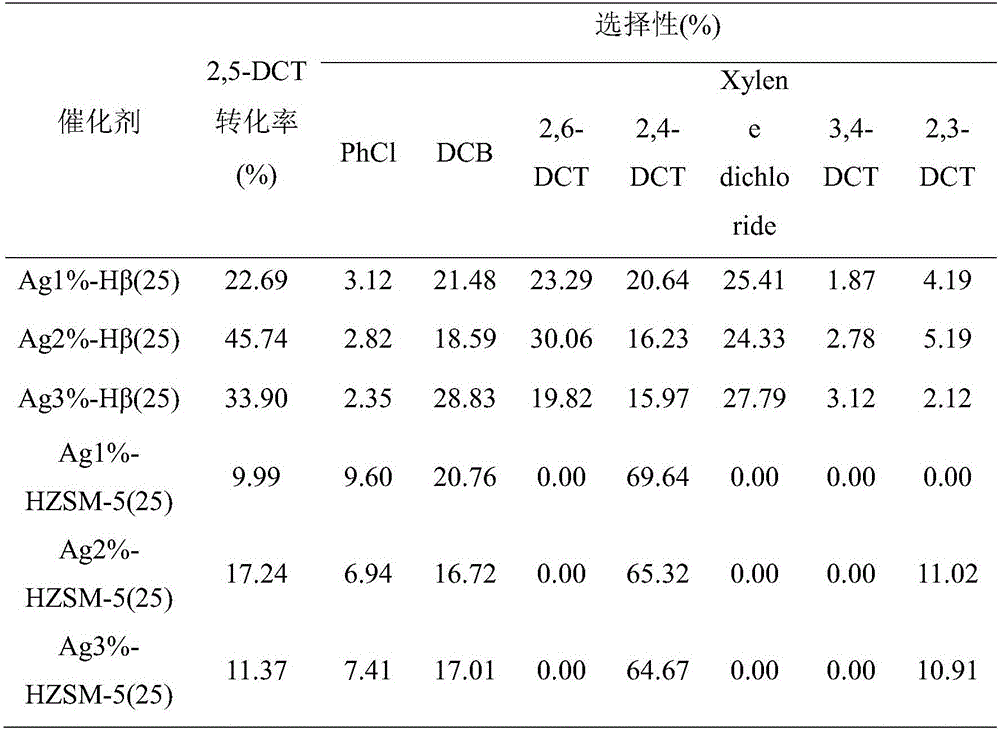

[0026] Changing the type of carrier molecular sieve to be HZSM-5(25) and the amount of loaded metal, it can be seen that different types of catalyst supports and metal loading have a great impact on the isomerization of 2,5-dichlorotoluene catalyzed by the loaded metal type H-type molecular sieve to prepare 2,6- The impact of dichlorotoluene, as shown in Table 1:

[0027] Table 1 The effect of the type of supported metal-type molecular sieve carrier and the amount of loaded metal on the conversion rate of raw materials and product selectivity

[0028]

[0029] Note: PhCl is chlorobenzene, DCB is dichlorobenzene, 2,6-DCT is 2,6-dichlorotoluene, 2,4-DCT is 2,4-dichlorotoluene, Xylene dichloride is dichloroxylene, 3 , 4-DCT is 3,4-dichlorotoluene, 2,3-DCT is 2,3-dichlorotoluene.

[0030] When the catalyst carrier is Hβ(25), the amount of loaded metal is 1%, the reaction temperature is 350°C, and the volume space velocity of the raw material solution is 0.4hr -1 , the convers...

Embodiment 2

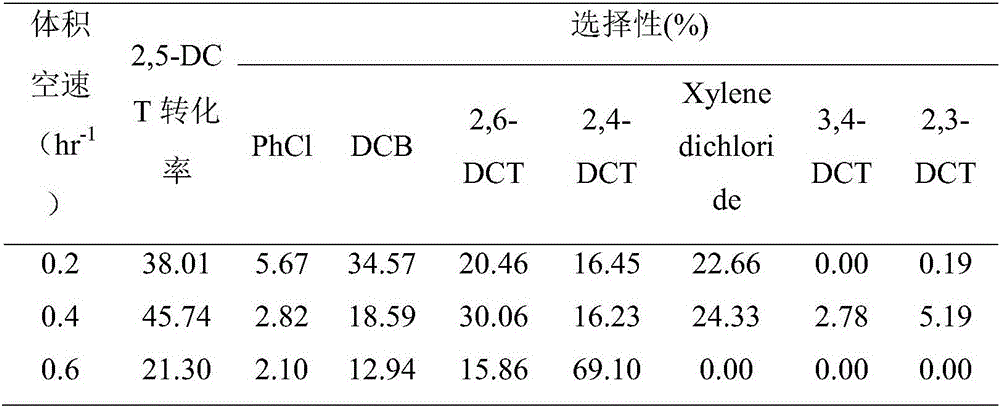

[0034] The process of isomerization of 2,5-dichlorotoluene adopts the same method as in Example 1, but the volume space velocity is 0.2hr when changing the raw material liquid -1 、0.6hr -1 , it can be seen that the volumetric space velocity of the raw material liquid has an influence on the H-type molecular sieve catalyzed isomerization of 2,5-dichlorotoluene to prepare 2,6-dichlorotoluene, as shown in Table 2:

[0035] Table 2 Effect of raw material liquid hourly volume space velocity on raw material conversion and product selectivity

[0036]

[0037] Note: PhCl is chlorobenzene, DCB is dichlorobenzene, 2,6-DCT is 2,6-dichlorotoluene, 2,4-DCT is 2,4-dichlorotoluene, Xylene dichloride is dichloroxylene, 3 , 4-DCT is 3,4-dichlorotoluene, 2,3-DCT is 2,3-dichlorotoluene.

[0038] When the raw material liquid volume space velocity is 0.2hr -1 , the conversion rate of 2,5-dichlorotoluene is 38.01%, the selectivity of 2,6-dichlorotoluene is 20.46%; the volumetric space veloci...

Embodiment 3

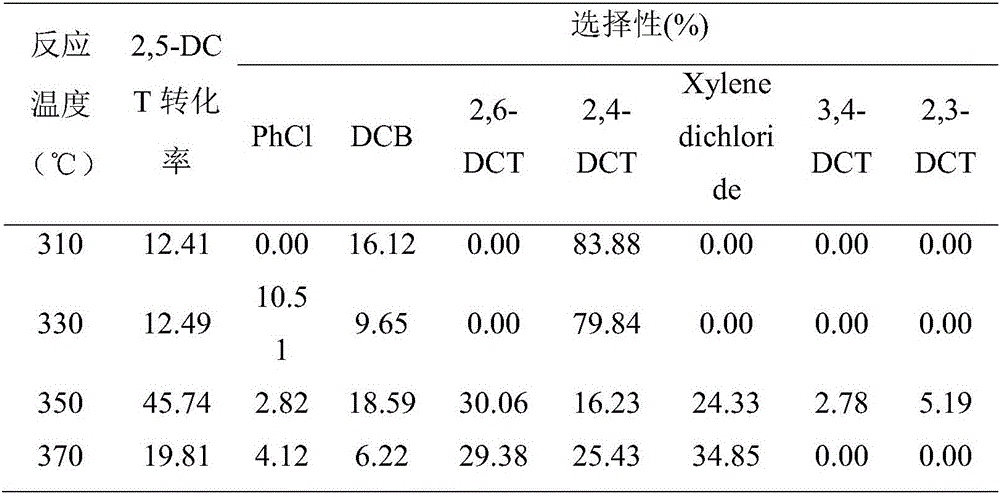

[0041]The process of isomerization reaction of 2,5-dichlorotoluene adopts the same method as that of Example 1, but the reaction temperature is changed to 310°C, 330°C, and 370°C. It can be seen that the reaction temperature has a great influence on the catalysis of 2,5-dichlorotoluene by H-type molecular sieve. The impact of the isomerization of chlorotoluene to prepare 2,6-dichlorotoluene is shown in Table 3:

[0042] Table 3 Effect of H-type molecular sieve types on raw material conversion and product selectivity

[0043]

[0044] Note: PhCl is chlorobenzene, DCB is dichlorobenzene, 2,6-DCT is 2,6-dichlorotoluene, 2,4-DCT is 2,4-dichlorotoluene, Xylene dichloride is dichloroxylene, 3 , 4-DCT is 3,4-dichlorotoluene, 2,3-DCT is 2,3-dichlorotoluene.

[0045] When the reaction temperature is 310°C, the conversion rate of 2,5-dichlorotoluene is 12.41%, and the selectivity of 2,6-dichlorotoluene is 0.00%; when the reaction temperature is 330°C, the conversion rate of 2,5-dich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com