Ultraviolet-quick-curing dendriform resin, and divergent preparation method and application thereof

A dendritic and ultraviolet light technology, applied in applications, household utensils, inks, etc., can solve the problems of high pollution of thermosetting resins, low production efficiency, slow curing speed, etc., to achieve faster curing speed, cost saving, surface drying time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

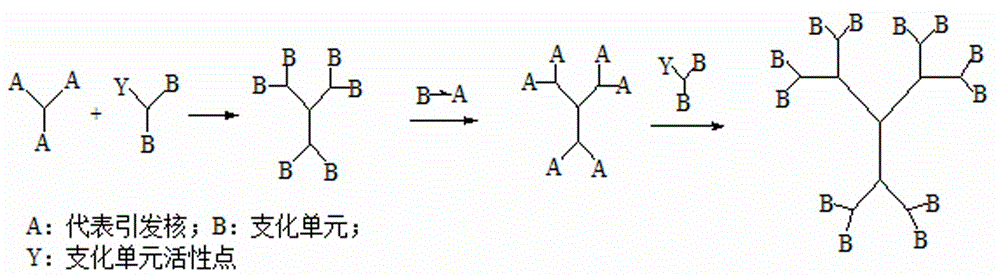

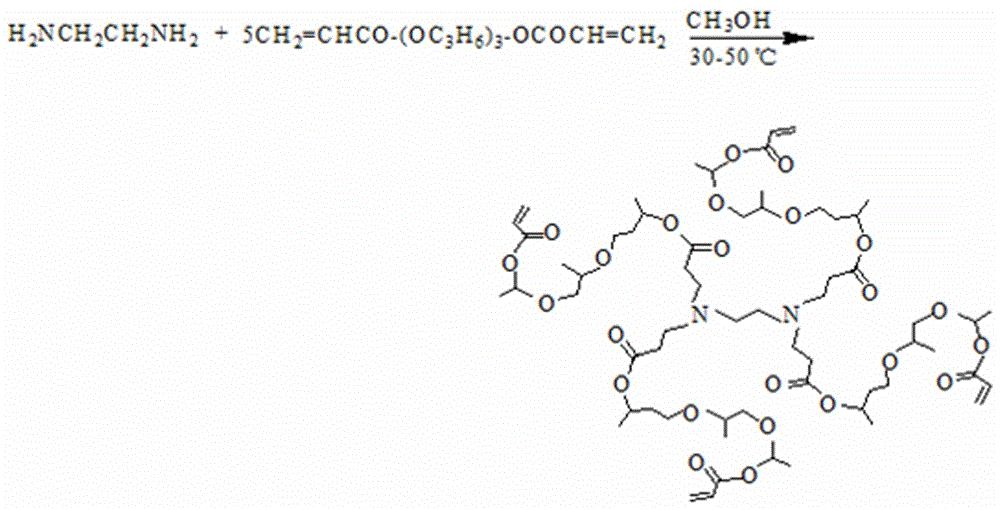

[0036] Such as figure 1 , 2 As shown, the present invention provides a high-speed UV-curable dendritic resin and its preparation method by a divergent method and its application.

[0037] With ethylenediamine (EDA), diethylenetriamine (DETA) and triethylenetetramine (TETA) containing different active H as the initiating core, tripropylene glycol diacrylate (TGPDA), ethoxylated trimethylol Propane triacrylate (TEPTA) is used as the branching unit, and the divergence method is used to prepare regular structure, highly branched, high double bond density, low viscosity, and the end group contains 4, 5, 6, 8, 10, 12 acrylate double Bond's first-generation dendritic series resins;

[0038] Select benzoin diethyl ether and 2-hydroxy-2-methyl-1-phenyl-1-propanone with different photoinitiating activities as photoinitiators, and respectively combine them with dendritic series resins with different acrylate double bonds in the end group in the darkroom. Mix well with each other, an...

Embodiment 1

[0040] The method for preparing ultraviolet light high-speed curing dendritic resin, the specific steps are as follows:

[0041] Product 1: Diamine (EDA) and difunctional acrylate monomer (TGPDA) to synthesize a dendritic resin with 4 acrylate double bonds in the end group.

[0042] (1) Add 25% catalyst methanol, 16.7% EDA, 83.3% TGPDA to a device equipped with a stirrer, a thermometer, and a constant temperature heating device. 2 Warm up to 35°C under protection, keep warm for 6 hours, distill under reduced pressure, and dry in vacuum to obtain a colorless and transparent liquid prepolymer;

[0043] (2) In the prepolymer synthesized in (1), add photoinitiator D-1173 accounting for 6% of the mass fraction of the prepolymer, and mix evenly in the dark room to obtain a colorless and transparent dendritic photosensitive resin product 1 , the viscosity is 10 mPa.s, low odor, good gloss, the prepared product is packed in metal or dark container, and stored away from light;

[004...

Embodiment 2

[0068] The method for preparing ultraviolet light high-speed curing dendritic resin, the specific steps are as follows:

[0069] Product 1: Diamine (EDA) and difunctional acrylate monomer (TGPDA) to synthesize a dendritic resin with 4 acrylate double bonds in the end group.

[0070] (1) Add 28% catalyst methanol, 16.7% EDA, 83.3% TGPDA to a device equipped with a stirrer, a thermometer, and a constant temperature heating device. 2 Under protection, the temperature was raised to 45°C, and the heat preservation reaction was carried out for 8 hours. After vacuum distillation and vacuum drying, a colorless and transparent liquid prepolymer was obtained;

[0071] (2) In the prepolymer synthesized in (1), add photoinitiator D-1173 accounting for 8% of the mass fraction of the prepolymer, and mix evenly in the dark room to obtain a colorless and transparent dendritic photosensitive resin product 1 , the viscosity is 20 mPa.s, low odor, good gloss, the prepared product is packed in m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com