Weaving yarn, weaving bag prepared by using weaving yarn, and production method of weaving bag

A technology for woven silk and woven bags, used in the field of woven silk, woven bags and woven bags, can solve the problems of strong resistance, and achieve good tensile and wear resistance, not easy to break or become brittle, and not easy to become brittle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

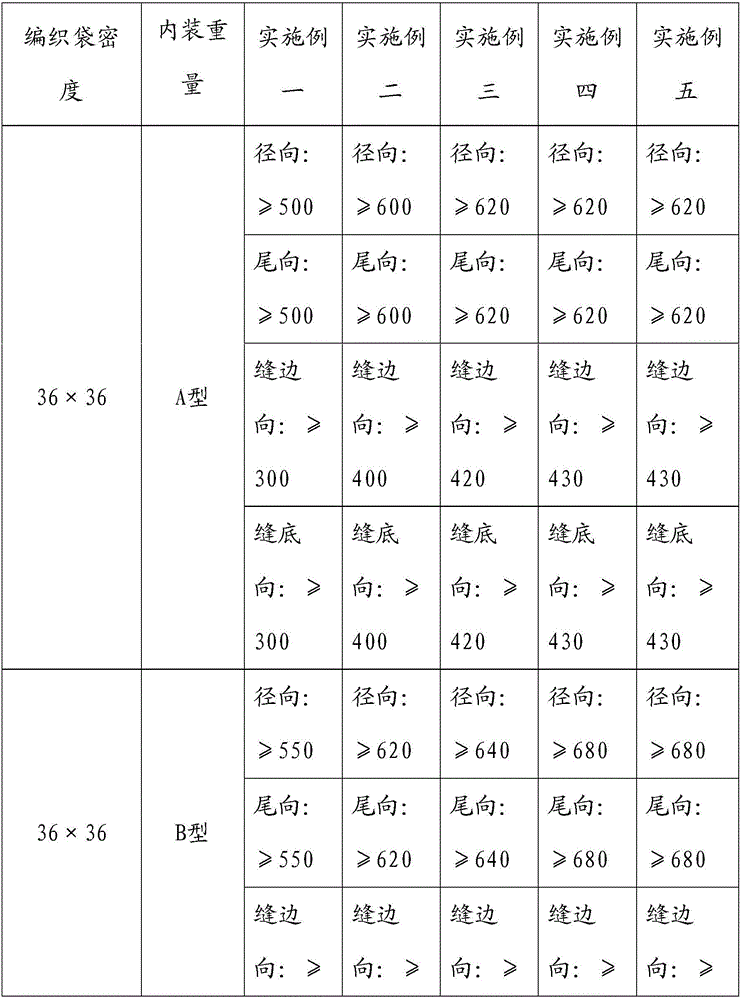

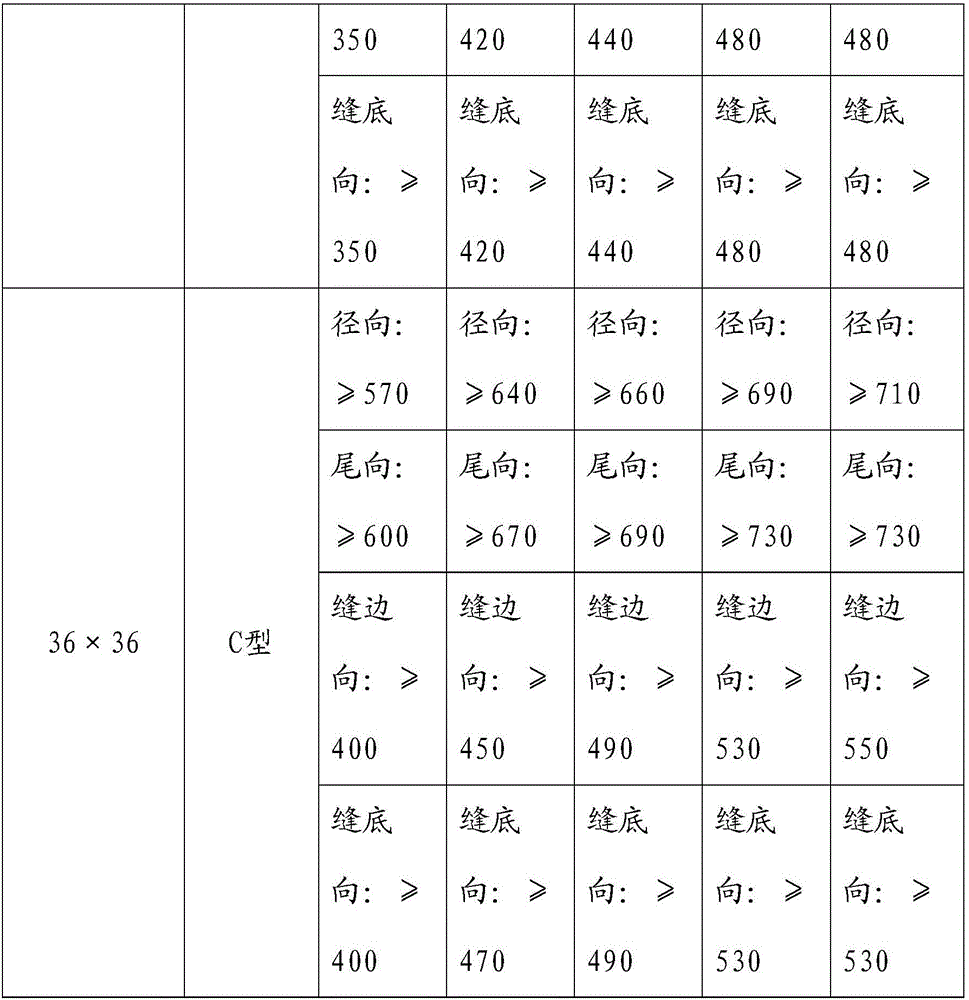

Examples

Embodiment 1

[0017] Embodiment 1: A kind of braided yarn, using the following components (parts by mass): ethylene-vinyl acetate copolymer: 20; polyvinyl alcohol: 35; isocyanate: 10; polyether glycol: 25; Amine: 15, tributyl citrate: 5; turpentine: 1; nano calcium carbonate: 0.5; linear low density polyethylene: 5; isocyanate: 3; polyether diol: 5; diethyltoluene diamine: 12 .

[0018] The surface of the braided silk is also coated with a coating material layer; the coating material layer adopts the following components (parts by mass): diethyltoluenediamine: 5; ultraviolet absorber UV-327: 0.5, auxiliary antioxidant DLTP: 0.8; polypropylene resin: 50; isocyanate: 2; polyether diol: 10.

[0019] A production method of a woven bag, the raw materials are melted, filtered, and extruded into a sheet film; the sheet film is cooled, dried, coated with a material layer, dried and cut into filaments; the filaments are heated, stretched, Cool into common flat yarn; use the above-mentioned flat ya...

Embodiment 2

[0020] Embodiment 2: A kind of braided yarn, using the following components (parts by mass): ethylene-vinyl acetate copolymer: 25; polyvinyl alcohol: 36; isocyanate: 13; polyether glycol: 30; Amine: 20, tributyl citrate: 7; turpentine: 1; nano calcium carbonate: 0.7; linear low density polyethylene: 8; isocyanate: 4; polyether diol: 8; diethyltoluene diamine: 13 .

[0021] The surface of the braided silk is also coated with a coating material layer; the coating material layer adopts the following components (parts by mass): diethyltoluenediamine: 7; ultraviolet absorber UV-327: 0.5, auxiliary antioxidant DLTP: 0.8; polypropylene resin: 60; isocyanate: 3; polyether diol: 13.

[0022] A production method of a woven bag, the raw materials are melted, filtered, and extruded into a sheet film; the sheet film is cooled, dried, coated with a material layer, dried and cut into filaments; the filaments are heated, stretched, Cool into common flat yarn; use the above-mentioned flat ya...

Embodiment 3

[0023] Embodiment 3: A kind of braided yarn, using the following components (parts by mass): ethylene-vinyl acetate copolymer: 28; polyvinyl alcohol: 37; isocyanate: 15; polyether glycol: 35; Amine: 23, tributyl citrate: 10; turpentine: 1; nano calcium carbonate: 2; linear low density polyethylene: 12; isocyanate: 5; polyether diol: 10; diethyltoluene diamine: 15 .

[0024] The surface of the braided silk is also coated with a coating material layer; the coating material layer adopts the following components (parts by mass): diethyltoluenediamine: 8; ultraviolet absorber UV-327: 0.5, auxiliary antioxidant DLTP: 0.8; polypropylene resin: 80; isocyanate: 10; polyether diol: 20.

[0025] A production method of a woven bag, the raw materials are melted, filtered, and extruded into a sheet film; the sheet film is cooled, dried, coated with a material layer, dried and cut into filaments; the filaments are heated, stretched, Cool into common flat yarn; use the above-mentioned flat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com