Nickel oxide nano-particles reinforced gas sensor and preparing method thereof

A gas sensor, nanoparticle technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as undiscovered reports, and achieve the effects of simple preparation process, low cost, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

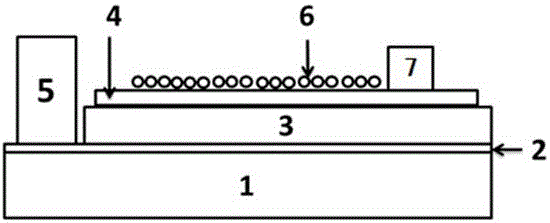

[0016] Example 1: 1) Clean the flexible polyimide substrate in deionized water and dry it; 2) deposit indium-doped magnesium tin oxide with a thickness of 40 nanometers on the flexible polyimide substrate by magnetron sputtering ; 3) Deposit a 6-micron thick magnesium tin oxide layer on the indium-doped magnesium tin oxide layer using physical vapor deposition technology, and reserve an area for growing the first electrode on the ITO layer; 4) transfer the single-layer graphene to the oxide on the magnesium tin layer; 5) Spin-coat the nickel oxide nanoparticle solution on the graphene, and reserve an area for growing the second electrode on the graphene; the diameter of the nickel oxide nanoparticle is 1nm-1μm; 6) on the graphene The reserved area and the reserved area on the ITO layer are coated with silver paste and dried; a graphene / magnesium tin oxide gas sensor reinforced with nickel oxide nanoparticles is obtained.

Embodiment 2

[0017] Example 2: 1) The glass substrate was cleaned in deionized water and dried; 2) Magnetron sputtering was used to deposit 200 nm thick fluorine-doped magnesium tin oxide on the glass substrate;

[0018] 3) Deposit an 8-micron thick magnesium tin oxide layer on the fluorine-doped magnesium tin oxide layer using physical vapor deposition technology, and reserve an area for growing the first electrode on the FTO layer; 4) Transfer three layers of graphene to magnesium oxide on the tin layer; 5) spray nickel oxide nanoparticle solution on the graphene, and reserve an area for growing the second electrode on the graphene layer; the diameter of the nickel oxide nanoparticles is 1nm-1μm; 6) on the graphene layer A gold electrode is thermally evaporated at the reserved area and on the reserved area on the fluorine-doped magnesium tin oxide layer; a graphene / magnesium tin oxide gas sensor enhanced by nickel oxide nanoparticles is obtained.

Embodiment 3

[0019] Example 3: 1) Clean the ceramic substrate in deionized water and dry it; 2) Use electron beam evaporation to deposit nickel metal with a thickness of 60 nanometers on the ceramic substrate; 3) Use a chemical water bath method on the nickel metal layer Deposit a 5 micron thick magnesium tin oxide layer, and reserve the area for growing the first electrode on the nickel metal layer; 4) transfer 10 layers of graphene to the magnesium tin oxide layer; 5) prepare nickel oxide nanoparticles on the graphene particle film, and reserve the area for growing the second electrode on the graphene layer; 6) screen-print silver electrodes on the reserved area of the graphene layer and the reserved area on the nickel metal layer; obtain nickel oxide nanoparticle-enhanced Graphene / MgSnO gas sensor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com